A boring machine

A technology of a boring machine and a boring tool holder, which is applied in the field of boring machines to achieve the effects of good boring controllability, high precision and improved operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

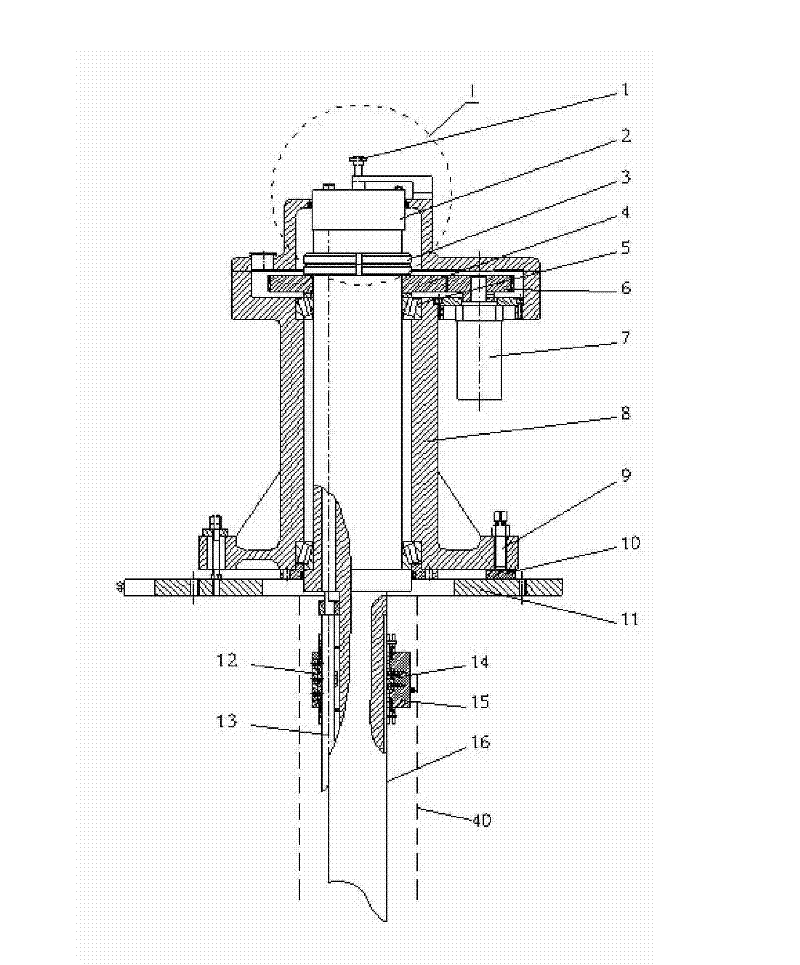

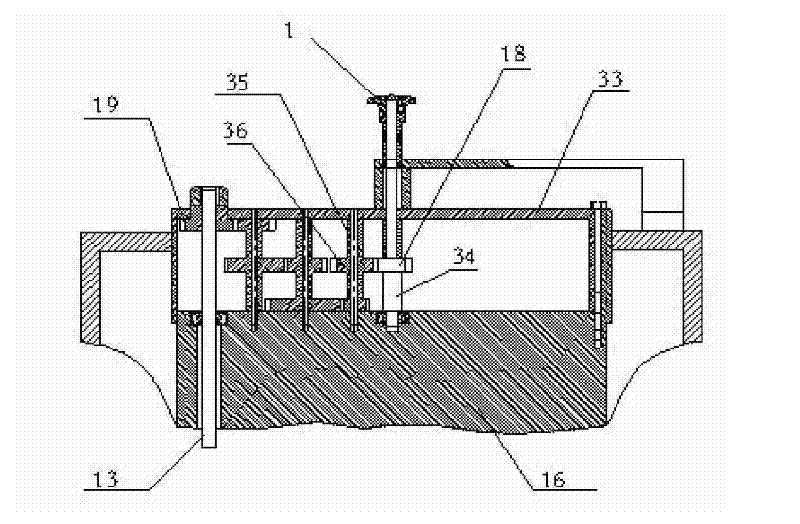

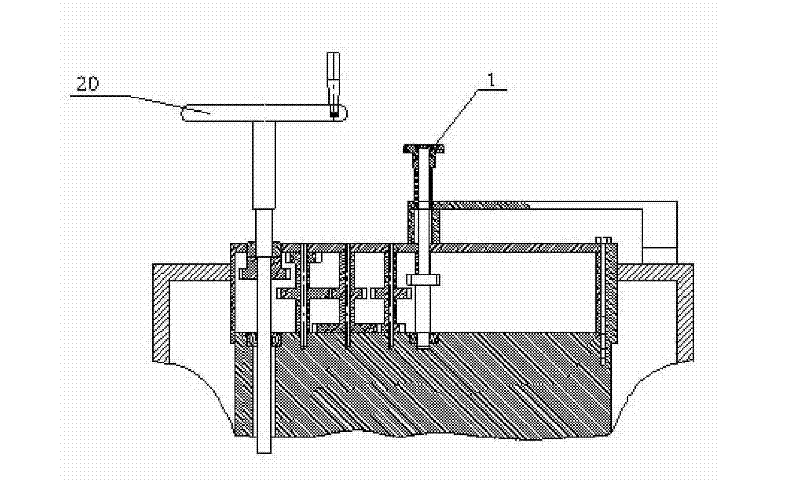

[0016] The boring machine of this specific embodiment is designed and manufactured for the boring process on the shipbuilding site. It needs to bore holes with a depth of φ220~φ340mm and a depth of 1500mm and an end face of φ200~φ500mm. The xxx ship stern rudder is made of MACR special steel with high strength and hardness. Large, general equipment can not be processed, and can not meet the technical requirements, hole cylindricity ≤ 0.03mm, verticality between the end face and the hole center line ≤ 0.03mm, surface roughness of the boring ≤ 3.2.

[0017] Such as figure 1 As shown, the stepless speed regulating machine 7 is driven by the hydraulic station, the stepless speed regulating machine 7 is connected with the driving gear 6 , and the driving gear 6 is connected with the driven gear 4 . The boring bar 16 is installed in the shell 8 through the round nut 3 located in the shell 8 and the E-class conical liquid subbearing. The shell 8 is fixedly connected with the ship pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com