Combined tenon-groove mechanism adapted to various shapes of slotted holes and tenon-groove method

A combined, mortise-and-groove technology, which is applied in the processing of dovetail tenon, wood processing equipment, manufacturing tools, etc., can solve the problems of low precision, achieve high precision, improve product quality, and reduce supplementary processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

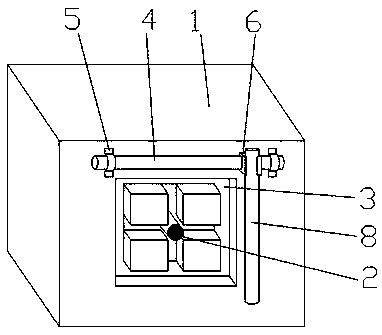

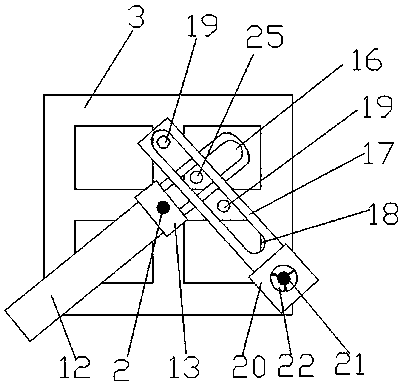

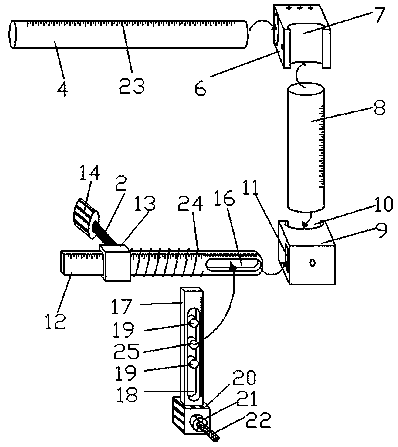

[0031] refer to Figure 1-4 , a combined tongue-and-groove mechanism adaptable to various shapes of slotted holes, including a rectangular frame body 1 and a drive shaft 2 pierced through the center of one side of the rectangular frame body 1, and one side of the rectangular frame body 1 is provided with a "Tian" shape The tank body 3 and the driving shaft 2 are set at the center point of the "Tian"-shaped tank body 3, and a horizontal slide bar 4 is arranged above the "Tian"-shaped tank body 3, and the two ends of the horizontal slide bar 4 are respectively hung by supports The ear 5 is fixed on the surface of the rectangular frame body 1 and there is a gap between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com