Turning-milling combined machining center of woodworking lathe

A compound machining center and woodworking lathe technology, which is applied to wood processing equipment, metal processing equipment, grinding machines, etc., can solve the problem of unprocessable asymmetric workpieces, save time for switching machines, avoid repeated positioning errors, and improve positioning progress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

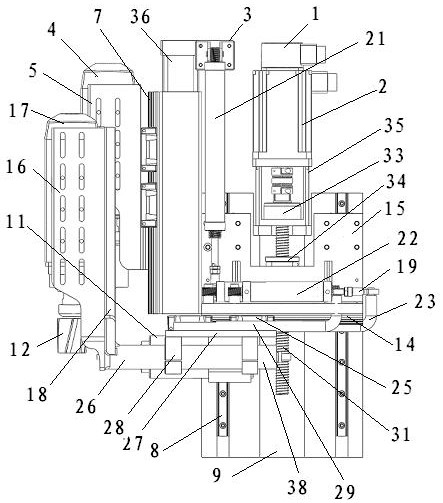

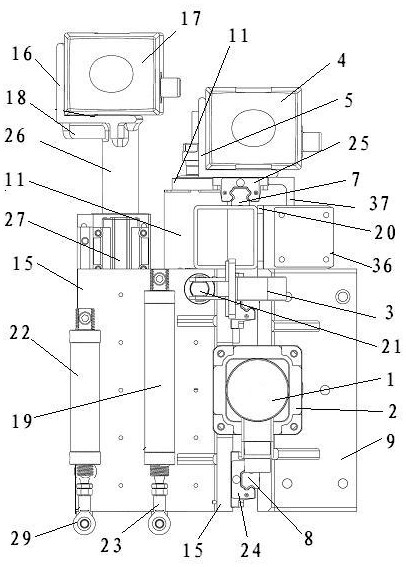

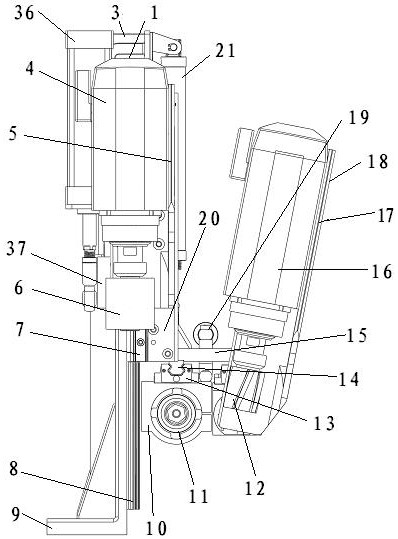

[0019] A woodworking lathe turning and milling compound machining center, including an assembly seat 9, a shaft grinding mechanism, a drilling shaft mechanism, a milling shaft mechanism, and a shaft slide plate 15, the shaft slide plate 15 and the assembly seat 9 are both in an “L” design, and the shaft slide plate 15 The two facades of the assembly seat 9 face away from the warp beam slider 24 and are relatively mobile connected with the shaft slide guide rail 8; On one side, move relatively up and down with shaft slide plate 15; The connection between the shaft slide plate 15 and the assembly seat 9 includes the shaft movement servo motor 2, the servo motor support 35, the screw rod 31, the axle sleeve 33, the thread sleeve 34, the servo motor support 35 is installed on the assembly seat 9, and the shaft movement servo The motor 2 is installed on the servo motor bracket 35, the shaft sleeve 33 is installed on the servo motor bracket 35, the screw rod 31 is connected to the s...

Embodiment 2

[0021] On the basis of Embodiment 1, a buffer cylinder 21 is also included. One end of the buffer cylinder 21 is connected to the shaft slide plate 15, and the other end is connected to the assembly seat 9 for pulling the shaft slide plate 15 so that it can move up and down easily and smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com