Vertical semi-dovetail tenon node connection structure for wood structure building beam column

A node connection and wood structure technology, applied in the direction of building structure, construction, etc., can solve the problems of inability to install and use, weakened column cross-section, easy to pull out tenon and other problems, achieve convenient installation, improve anti-extraction tenon ability, and improve the overall Effects of stiffness and overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0033] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

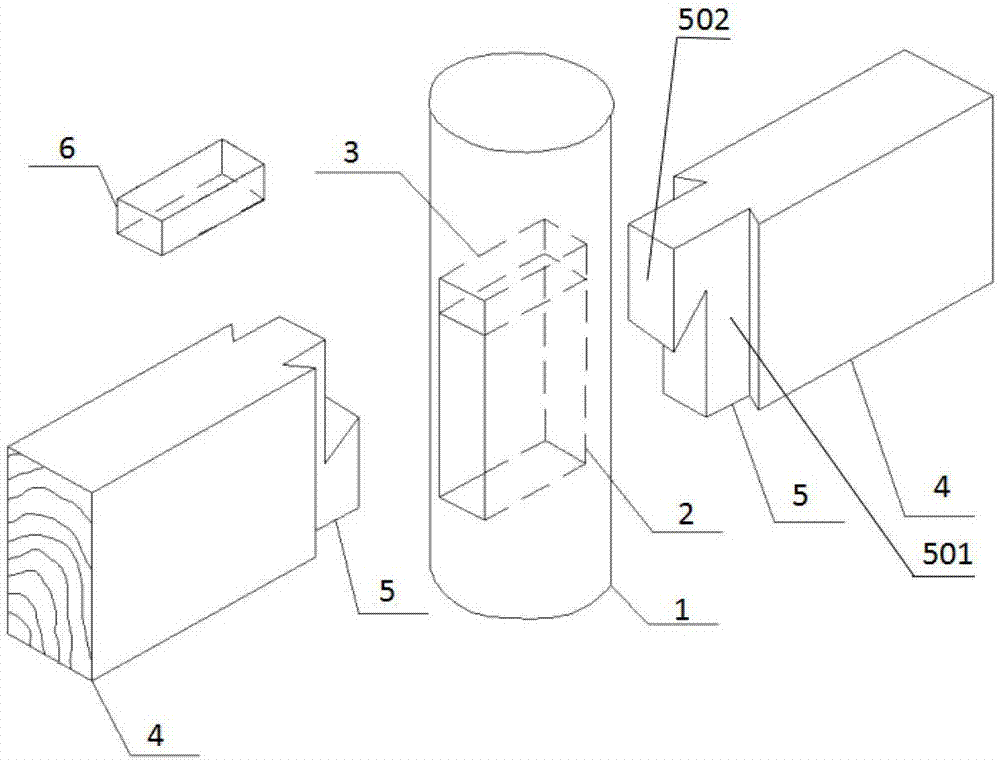

[0034] figure 1 It shows a vertical semi-dovetail joint connection structure for beams and columns of a wooden structure building. A mortise 2 and a center column cork hole 3 above the mortise 2 are arranged on the center column 1 of the wooden structure building; The two wooden beams I4 connected with the central column 1 are respectively provided with matching vertical half-dovetail joints I5; wherein, the two wooden beams I4 are connected to the central column 1 through matching vertical half-dovetail joints I5 After the two wooden beams I4 are matched and connected, a woode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com