Mortise type prefabricated comprehensive pipe gallery longitudinal connector

A technology for longitudinal joints and comprehensive pipe galleries, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as incomplete waterproof performance, achieve rich structural forms, improve mechanical and waterproof performance, and have good waterproof performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the accompanying drawings and embodiments.

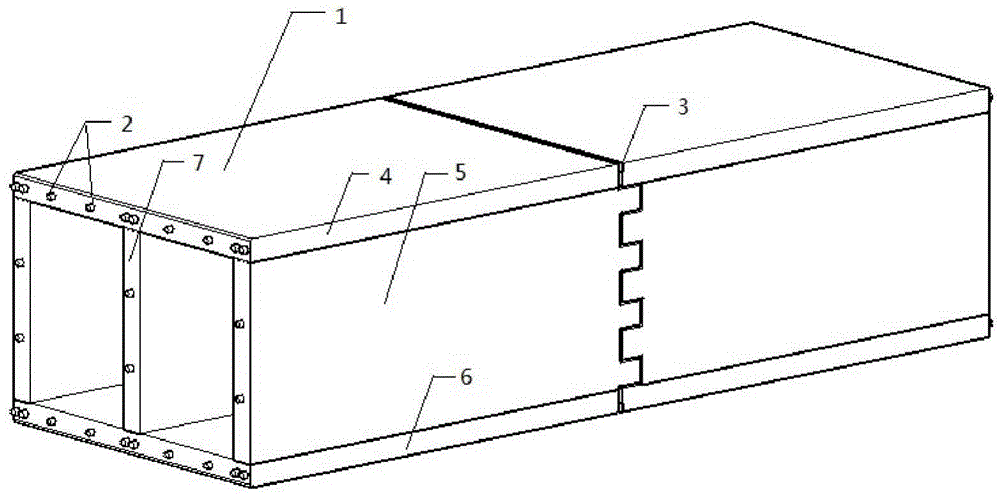

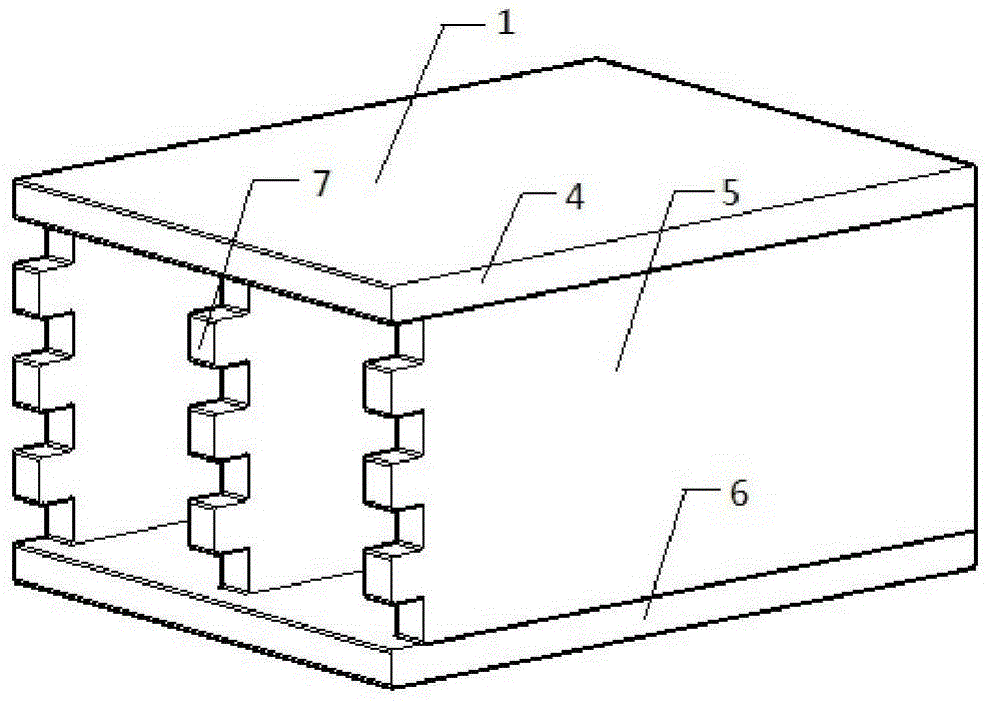

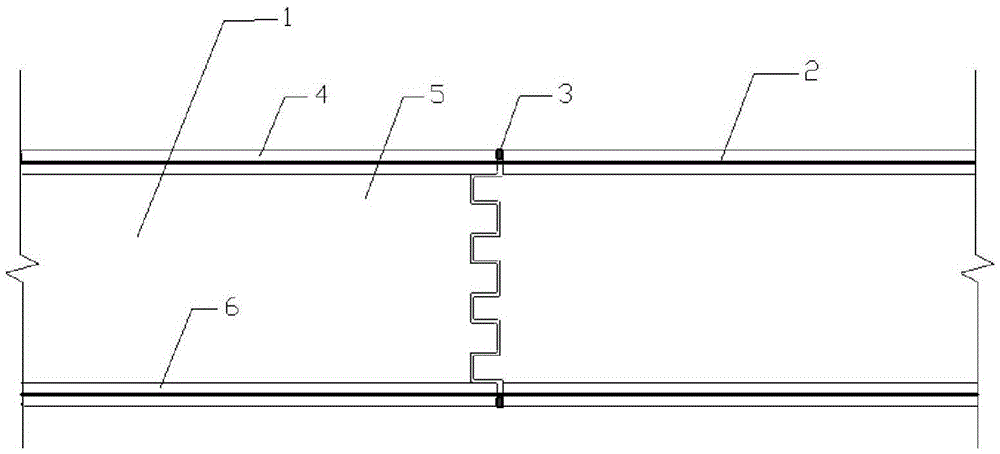

[0016] like Figures 1 to 2 As shown, the present invention is a longitudinal joint of a tongue and groove type prefabricated integrated pipe gallery, which is characterized in that: the longitudinal joint comprises a prefabricated pipe gallery segment 1, a longitudinal prestressed rib 2 and a water-stop rubber belt 3, wherein the prefabricated pipe gallery Section 1 includes a top plate 4, a side plate 5, and a bottom plate 6; the two ends of each pipe gallery side plate 5 are respectively made into mortise and tenon members that match each other. The relationship is matched with each other, water-stop rubber belts are reasonably arranged at the joints, and then prestressed by longitudinal prestressing ribs for tensioning, so that the prefabricated pipe gallery forms an overall structure.

[0017] In the present invention:

[0018] The cross-sectional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com