Elevator guide rail automatic production line manufacturing technique and equipment thereof

An automatic production line, elevator guide rail technology, applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve problems such as low production efficiency, work-related accidents, and human resource consumption, so as to avoid product quality differences and reduce work Strength, the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

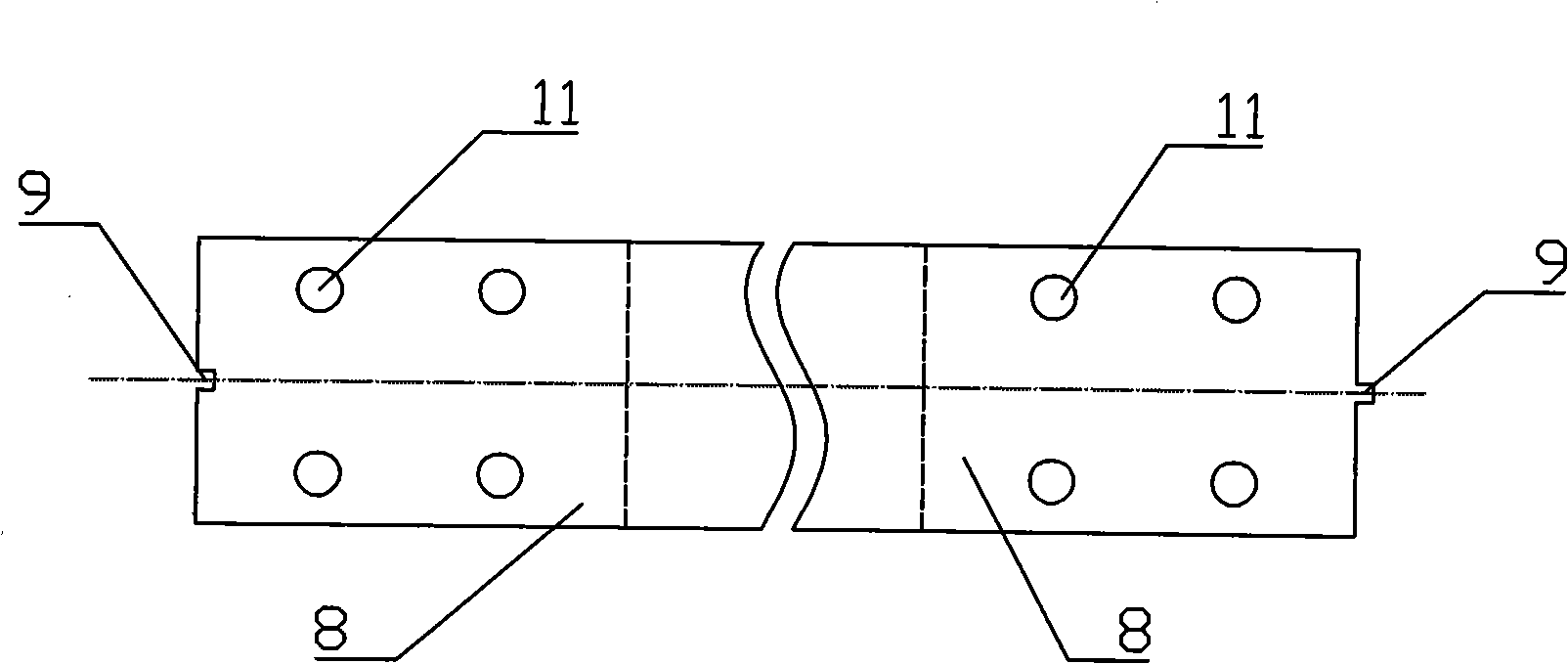

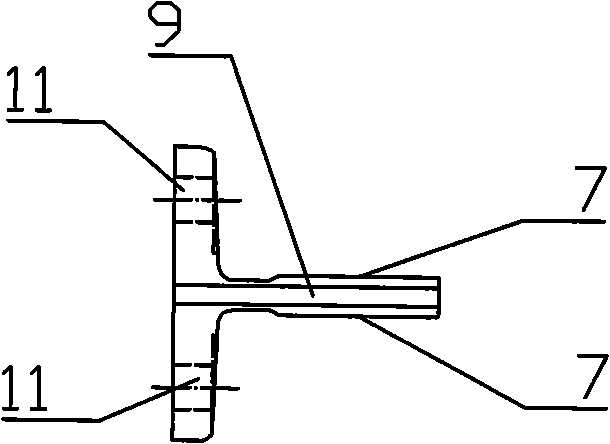

[0024] Such as figure 1 , 2 The elevator guide rail shown is a T-shaped elevator guide rail. The elevator guide rail needs to be processed, including the sides of the two elevator guide rails 7, the large back mounting surface at both ends 8, the female tenon at one end of the elevator, and the male tenon at one end. Large back mounting holes 11 on the back mounting surface 8.

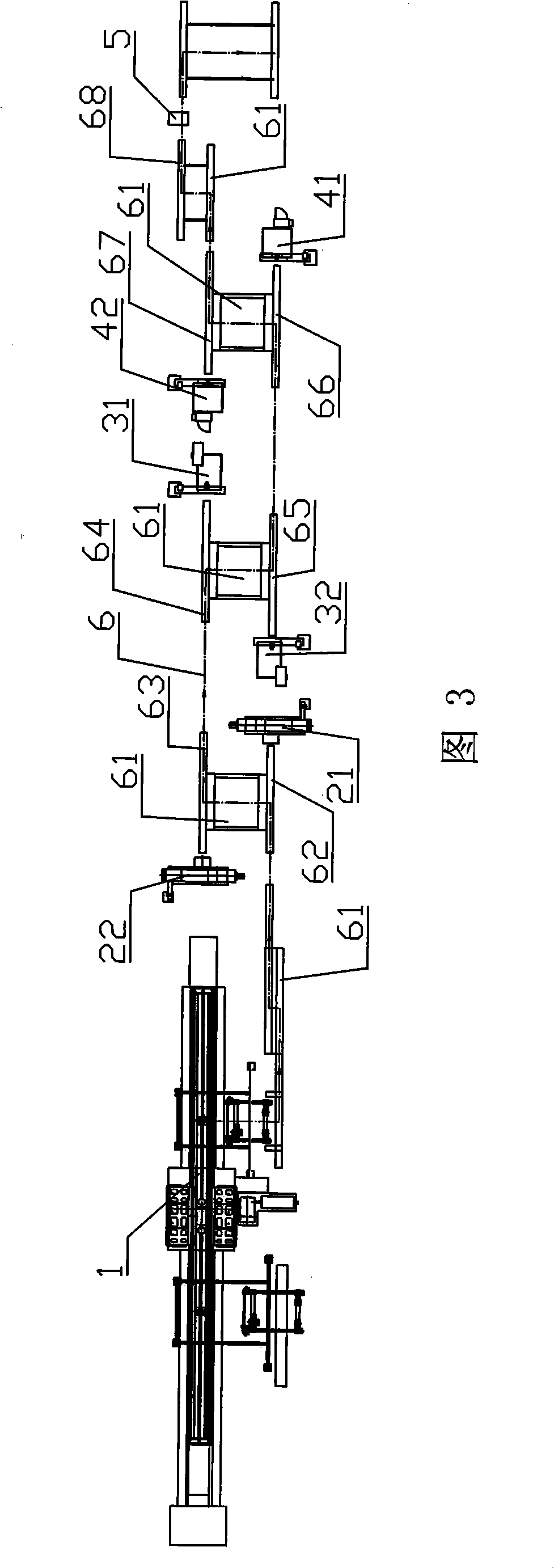

[0025] As shown in Figure 3, a kind of elevator guide rail automatic production line production process, the specific steps of this production process are as follows:

[0026] A. Send the elevator guide rails into the elevator guide rail two side surface processing equipment 1 to process the elevator guide rail both sides (7), after the processing is completed, the elevator guide rails are transported forward by the conveying feeding system 6;

[0027] B. The conveying and feeding system 6 transports the elevator guide rail forward into the first elevator guide rail large back milling processing equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com