Honeycomb lattice enhanced type composite material double-cylinder structure and anti-collision system using same

A composite material and anti-collision system technology, which is applied in the field of honeycomb lattice reinforced composite material double-tube structure and the anti-collision system applying the same, can solve the problems of poor anti-collision effect, high cost, difficult repair, etc. The effect of strong ability, moderate manufacturing cost and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

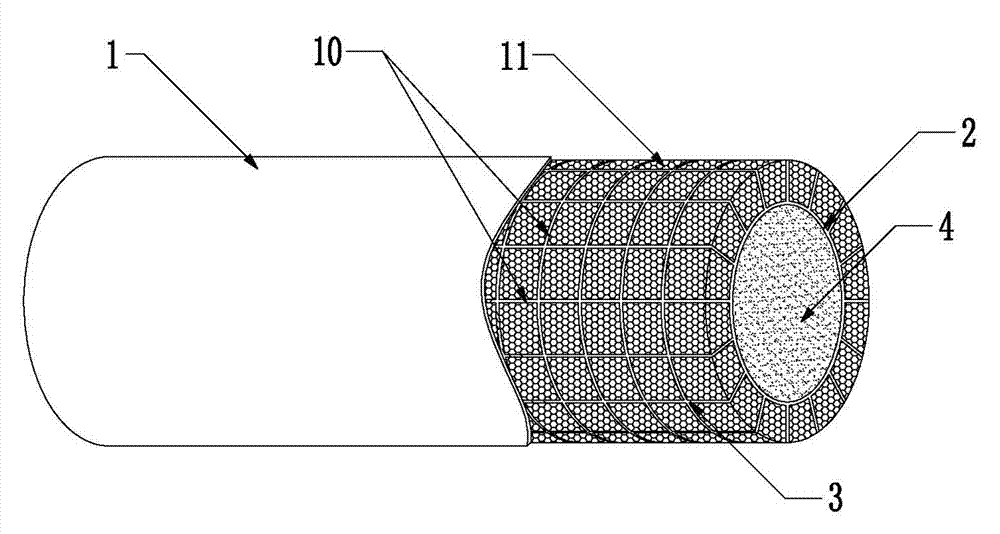

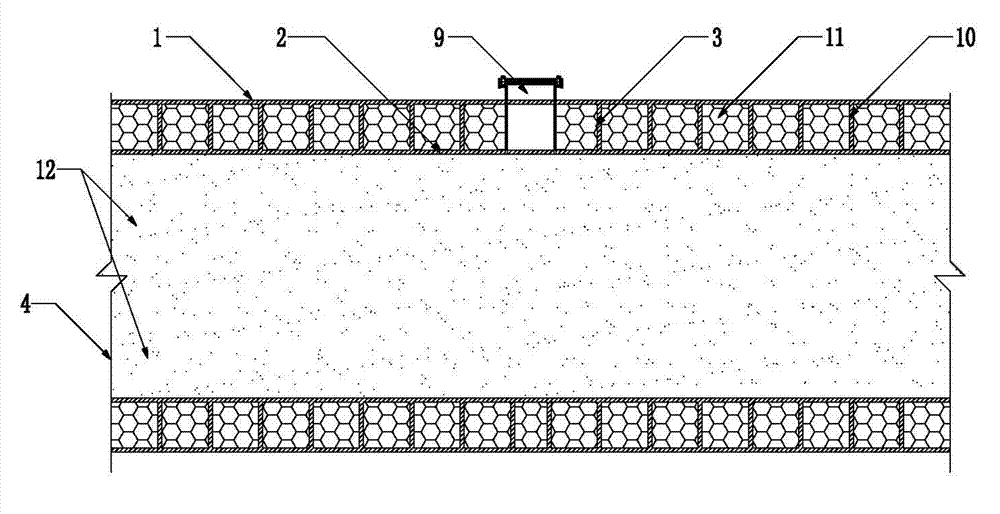

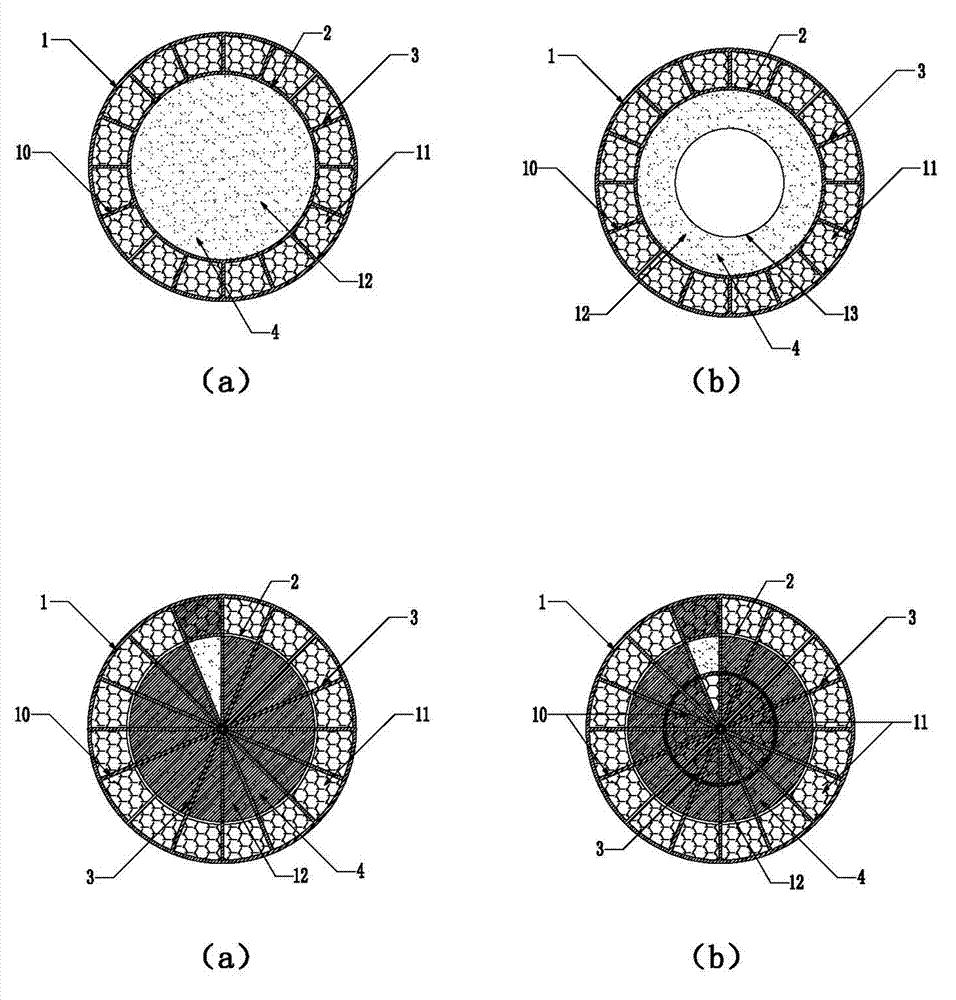

[0033] Such as Figure 6 As shown, a honeycomb lattice-reinforced double-tube structure of composite material, the double-tube structure is composed of 4 straight tube units 5 with equal cross-section and 4 curved tube units 6, and mortise and tenon joints are used between the straight tube units 5 and curved tube units 6 The joint 7 and the latch rod 17 are connected as a whole and arranged around the bridge tower column. In order to realize the anti-collision system floating with the water level, a polytetrafluoroethylene plate is installed between the anti-collision system and the pier as a mobile device 8 . The straight cylinder unit 5 and the curved cylinder unit 6 are mainly composed of an outer cylinder 1, an inner cylinder 2, a honeycomb lattice reinforcement 3 woven between the inner cylinder 1 and the outer cylinder 2, and a filling material body 4 filled in the inner cylinder 2. During specific molding, glass fibers are laid in the mold, and the polyurethane foam w...

Embodiment 2

[0035] Such as Figure 7 As shown, a honeycomb lattice-reinforced double-tube structure of composite material, the anti-collision structure is composed of 6 straight tube units 5 with equal cross-section, 4 straight tube units 5 with variable cross-section and 8 curved tube units 6, and the adjacent straight tube units 5 Between them or between the straight cylinder unit 5 and the curved cylinder unit 6, they are connected as a whole by mortise and tenon joints 7 and latch rods 17, and are arranged around the bridge cap. In order to realize the anti-collision system floating with the water level, a honeycomb lattice reinforced column is installed between the anti-collision system and the bridge pier as a mobile device 8, and the honeycomb lattice reinforced column is formed by vacuum introduction of glass fiber and paulownia wood. Considering the different risks of ship collision on each side of the pier, a large-diameter double-tube structure is set on the collision side, and...

Embodiment 3

[0037] Such as Figure 8 As shown, a honeycomb lattice-reinforced double-tube structure of composite material, the anti-collision structure is composed of 10 straight tube units 5 of equal cross-section and 6 curved tube units 6, between adjacent straight tube units 5 or straight tube units 5 and curved tube units The cylinder units 6 are connected as a whole by mortise and tenon joints 7 and latch rods 17, and are arranged around the bridge pier body. In order to realize the anti-collision system floating with the water level, a plastic slide plate is installed between the anti-collision system and the pier as the mobile device 8 . In order to effectively shift away from the ship's driving direction, the anti-collision section on the collision side is set as a sharp point, so as to ensure that the ship will not directly hit the pier. The straight cylinder unit 5 and the curved cylinder unit 6 are mainly composed of an outer cylinder 1, an inner cylinder 2, a honeycomb lattic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com