A highway composite material sandwich anti-collision guardrail

A composite material, anti-collision guardrail technology, applied in the direction of roads, roads, road safety devices, etc., can solve the problems of infrastructure, uneconomical utilization of resources and land, heavy structures of concrete guardrails and metal guardrails, and loss of protective effect of protective coatings. , to achieve the effect of flexible shape design, low maintenance cost and good energy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In conjunction with the accompanying drawings, the working principle and specific technical solutions of the patent of the present invention are described in detail:

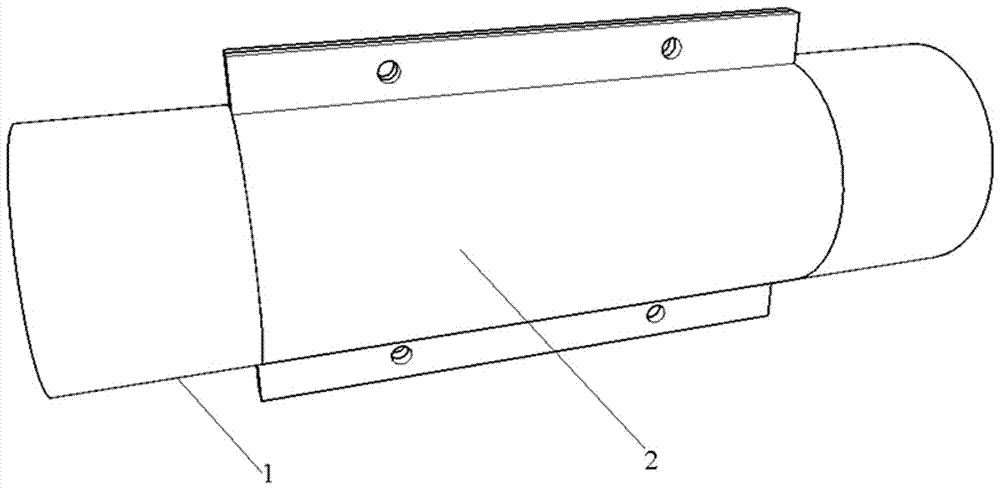

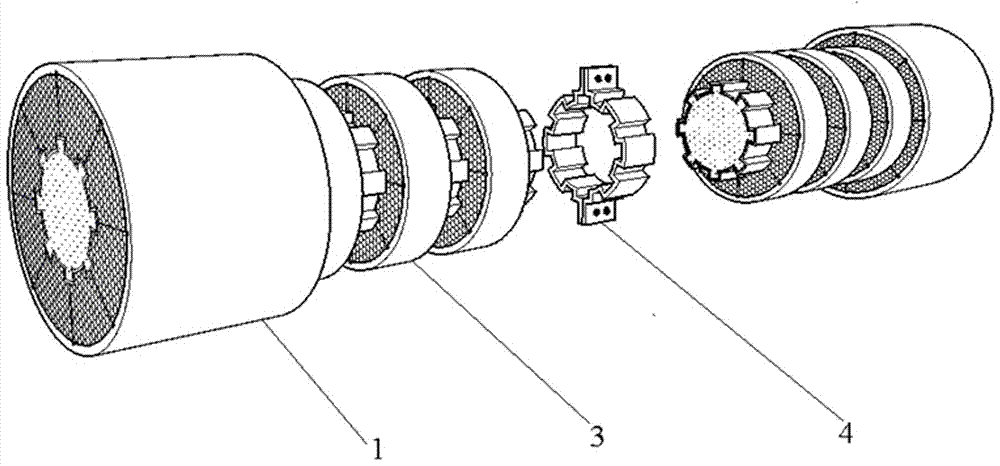

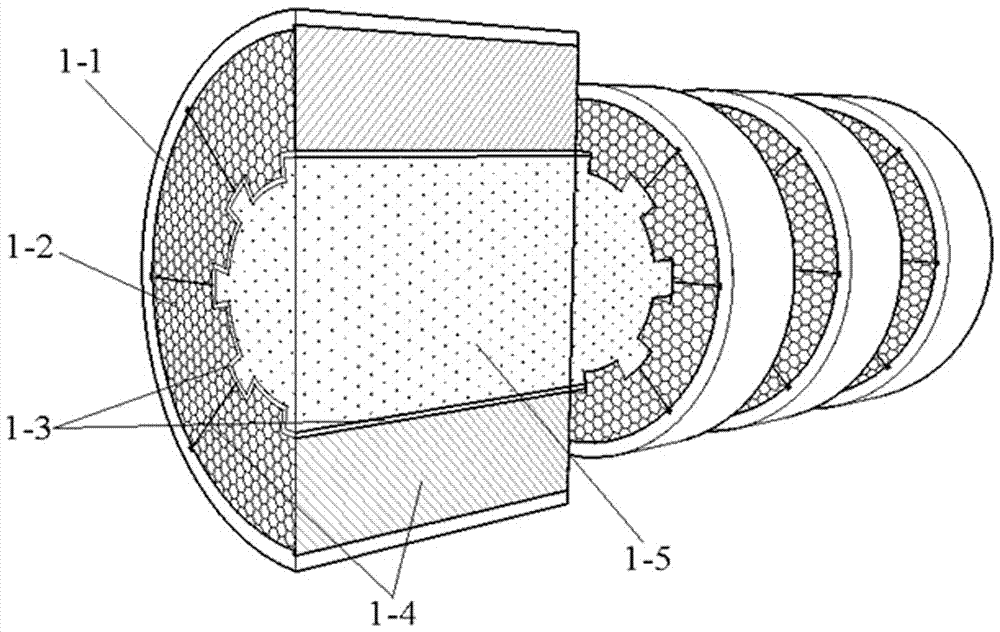

[0021] Such as figure 1 , 2 , 3, 4, and 5, a composite material sandwich highway crash barrier includes a number of crash bar units 1, convex rings 3, fasteners 4 and curved cover plates 2. Wherein the crash bar unit 1 includes a hollow cylindrical shell 1-1, a hollow cylindrical inner shell 1-3, a metal rib 1-4 on the inner shell, a sandwich filler 1-5 and an energy dissipation filler 1- 2. The shell 1-1 is made of fiber reinforced materials, including at least one of carbon fiber, glass fiber, basalt fiber, aramid fiber, hybrid fiber and unsaturated polyester resin, vinyl resin, epoxy resin, inorganic resin or thermoplastic resin At least one of the materials is solidified and molded, the inner shell 1-3 is made of light metal thin-walled pipes such as aluminum or aluminum alloy, the longitudinal sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com