Beam and column joint structure of timber architecture

A beam-column connection and node structure technology, applied in building construction, construction, etc., can solve the problems of increased construction cost, low rigidity of mortise and tenon joints, and decreased mechanical properties at nodes, and achieves bending and tensile capacity. Improved, easy node installation, simple node structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

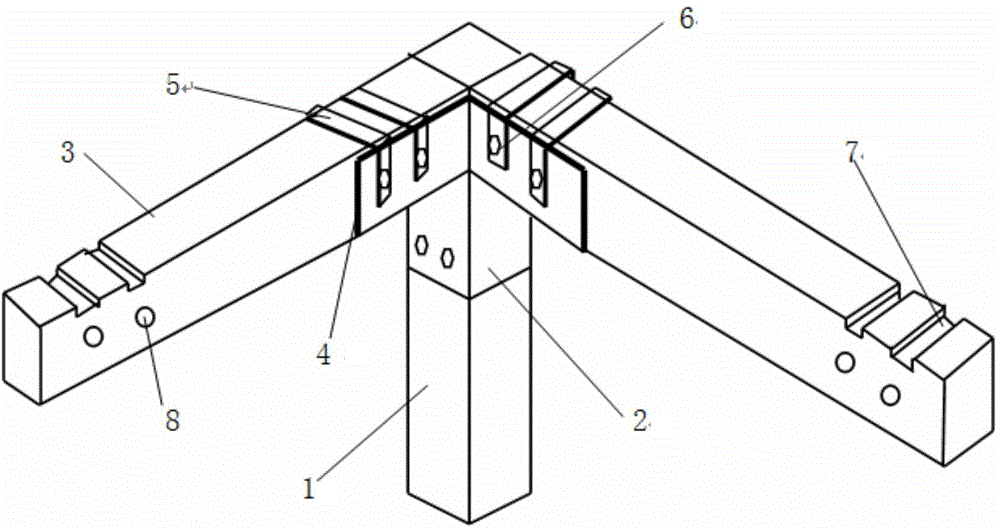

[0021] This embodiment is a connection node formed by the present invention by two wooden beams and a column in a wooden structure building.

[0022] Such as figure 1 As shown, two wooden beams 3 and a wooden column 1 of this node are connected into one body by a steel connector.

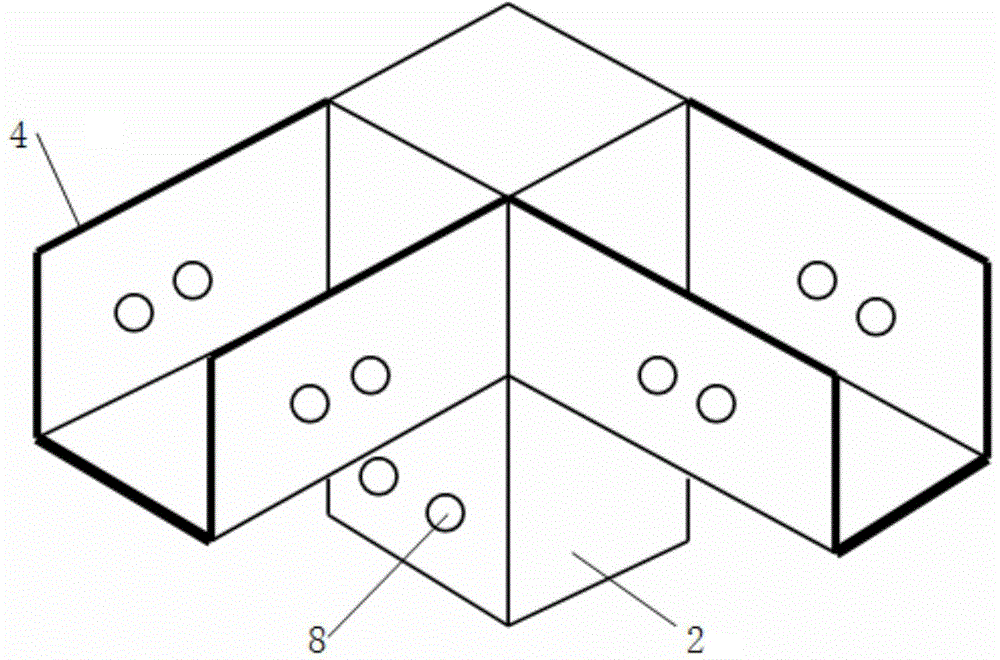

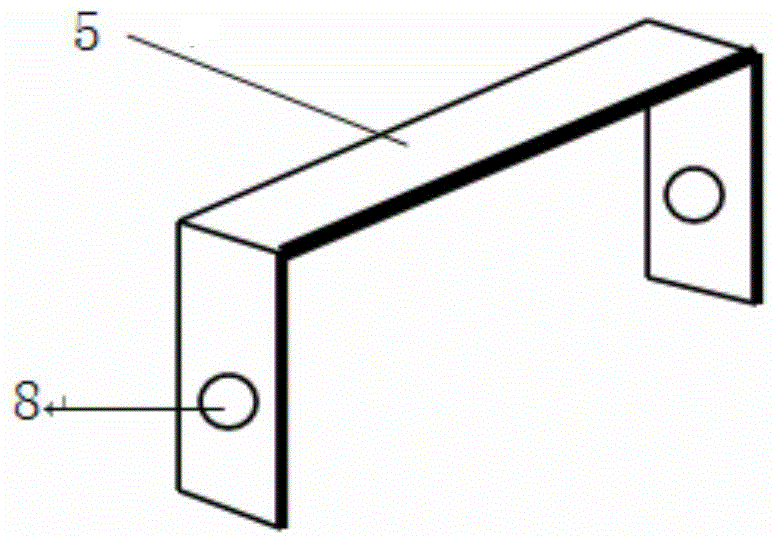

[0023] The steel connectors such as figure 2 As shown, it consists of a square sleeve 2 and two "U" shaped grooves 4 welded vertically to the upper side wall of the square sleeve. The inner dimension of the square sleeve is the same as the external dimension of the wooden column, the groove width of the "U" shaped groove is the same as the width of the wooden beam, and the depth of the "U" shaped groove is smaller than the thickness of the wooden beam, so that the upper surface of the wooden beam It is higher than the wall of the "U"-shaped groove (the height is the same as the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com