Latent curing single-component polyurethane water-proof coating and preparation method thereof

A polyurethane waterproof, one-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of increasing the correctness of the formula and not completely solving the problem of foaming, etc., to solve the slow curing speed, reduce viscosity, improve The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A latent curing one-component polyurethane waterproof coating, calculated in parts by weight, its composition and content are as follows:

[0041] 30 parts of toluene diisocyanate

[0042] 120 parts of polyether diol

[0043] 30 parts of polyether trihydric alcohol

[0044] Chlorinated paraffin 140 parts

[0045] Calcium carbonate 400 parts

[0046] Silane coupling agent 0.3 parts

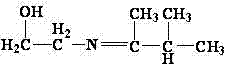

[0047] Acetone-Ethylenediamine Condensate 8 parts

[0048] Catalyst 0.8 parts

[0049] Thinner 120 parts

[0050] Described catalyst is dibutyltin dilaurate;

[0051] Described diluent is 200# solvent naphtha.

[0052] The preparation method of above-mentioned a kind of latent curing one-component polyurethane waterproof coating comprises the steps:

[0053]Add 120 parts of polyether diol, 30 parts of polyether triol, 140 parts of chlorinated paraffin, and 0.3 part of silane coupling agent into the reaction kettle, start stirring, heat to 105°C to dissolve and mix for 30 minutes, an...

Embodiment 2

[0058] A latent curing one-component polyurethane waterproof coating, calculated in parts by weight, its composition and content are as follows:

[0059] 50 parts of diphenylmethane diisocyanate

[0060] 150 parts of polyether diol

[0061] 40 parts of polyether trihydric alcohol

[0062] Chlorinated paraffin 170 parts

[0063] Kaolin 500 parts

[0064] Silane coupling agent 0.5 part

[0065] Methyl isobutyl ketone-ethanolamine condensate 15 parts

[0066] Catalyst 1.1 parts

[0067] Thinner 165 parts

[0068] Described catalyst is stannous octoate;

[0069] Described diluent is solvent naphtha S150.

[0070] The preparation method of above-mentioned a kind of latent curing one-component polyurethane waterproof coating comprises the steps:

[0071] Add 150 parts of polyether diol, 40 parts of polyether triol, 170 parts of chlorinated paraffin, and 0.5 part of silane coupling agent into the reaction kettle, start stirring, heat to 105°C to dissolve and mix for 30 minut...

Embodiment 3

[0076] A latent curing one-component polyurethane waterproof coating, calculated in parts by weight, its composition and content are as follows:

[0077] 26 parts of toluene diisocyanate

[0078] 10 parts diphenylmethane diisocyanate

[0079] 150 parts of polyether diol

[0080] 30 parts of polyether trihydric alcohol

[0081] Chlorinated paraffin 160 parts

[0082] Calcium carbonate 300 parts

[0084] 0.45 parts of silane coupling agent

[0085] Acetone-Ethylenediamine Condensate 5 parts

[0086] Methyl isobutyl ketone-ethanolamine condensate 5 parts

[0087] Catalyst 0.9 parts

[0088] Thinner 150 parts

[0089] The catalyst is a mixture of dibutyltin dilaurate and stannous octoate in a mass ratio of 4:5;

[0090] The diluent is calculated by mass ratio of 200# solvent oil and solvent oil S150, that is, the mixture of 200# solvent oil: solvent oil S150 is 1:1.

[0091] The preparation method of above-mentioned a kind of latent curing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com