High-elasticity heat-conducting environment-friendly polyurethane sealant

A polyurethane sealant, environmentally friendly technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of long-term heat resistance, environmental pollution, insufficient elasticity, etc., to save wood, save The effect of natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0043] Preparation of prepolymer (I):

[0044] Raw materials and their weight percentages:

[0045] Polyoxypropylene Triol 76%

[0046] Diphenylmethane-4,4'diisocyanate 12.5%

[0047] Diisodecyl phthalate 11.5%

[0048] The prepared prepolymer has an isocyanate content of 2.9%

[0049] Preparation of prepolymer (II):

[0050] Raw materials and their weight percentages:

[0051] Polyoxypropylene glycol 80%

[0052] Diphenylmethane-4,4'diisocyanate 8.5%

[0053] Diisodecyl phthalate 11.5%

[0054] The prepared prepolymer has an isocyanate content of 2.3%

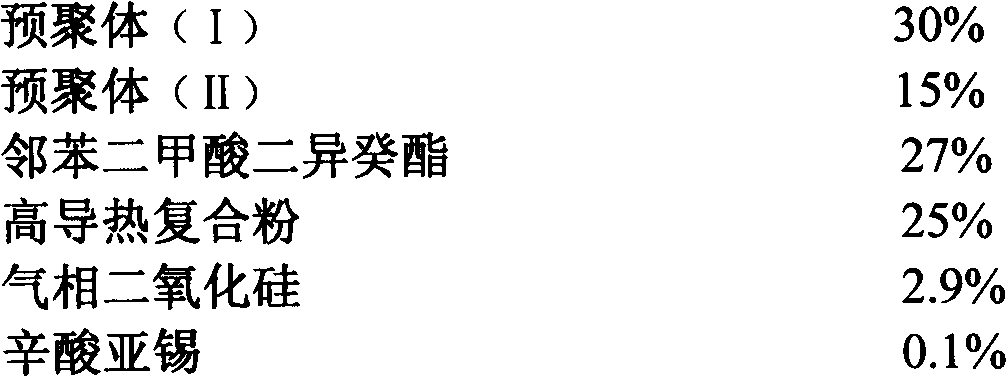

[0055] Preparation of sealant:

[0056]

example 2

[0058] Preparation of prepolymer (I):

[0059] Raw materials and their weight percentages:

[0060]Polyoxypropylene Triol 77%

[0061] Toluene diisocyanate 9.1%

[0062] Diisodecyl phthalate 13.9%

[0063] The prepared prepolymer has an isocyanate content of 3.2%

[0064] Preparation of prepolymer (II):

[0065] Raw materials and their weight percentages:

[0066] Polyoxypropylene glycol 82%

[0067] Toluene diisocyanate 6.1%

[0068] Diisodecyl phthalate 11.9%

[0069] The prepared prepolymer has an isocyanate content of 2.3%

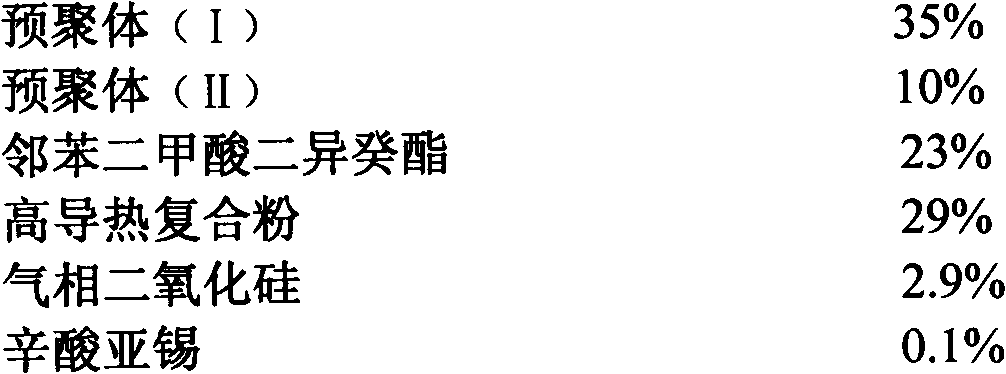

[0070] Preparation of sealant:

[0071]

example 3

[0073] Preparation of prepolymer (I):

[0074] Raw materials and their weight percentages:

[0075] Polyoxypropylene Triol 76%

[0076] Diphenylmethane-4,4'diisocyanate 12.5%

[0077] Diisodecyl phthalate 11.5%

[0078] The prepared prepolymer has an isocyanate content of 2.9%

[0079] Preparation of prepolymer (II):

[0080] Raw materials and their weight percentages:

[0081] Polyoxypropylene glycol 80%

[0082] Diphenylmethane-4,4'diisocyanate 8.5%

[0083] Diisodecyl phthalate 11.5%

[0084] The prepared prepolymer has an isocyanate content of 2.3%

[0085] Preparation of sealant:

[0086]

[0087]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com