Wet cured polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive, moisture-curing technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc. Low problems, to achieve the effect of improving performance requirements, convenient viscosity, and high initial viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

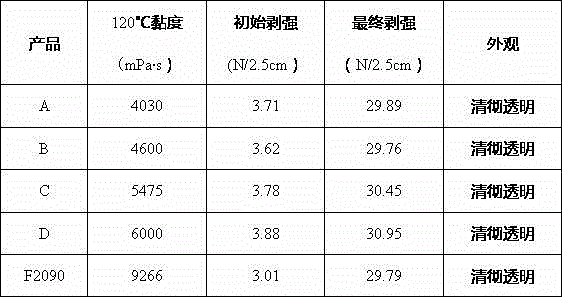

Examples

Embodiment 1

[0030] (1) Weigh 40.00g of propylene oxide diol with a molecular weight of 1000, 42.00g of polybutylene adipate diol with a molecular weight of 3000, 43.20g of propylene oxide diol with a molecular weight of 4000, and a total of 1.82g of antioxidants 1076 and 1010 , put it into a 500ml three-neck flask, and heat and stir at 120-130°C for vacuum dehydration for 30min, and the absolute pressure is lower than 100Pa;

[0031] (2) Release the vacuum, then add 45.39g of polyacrylic acid resin while stirring, then raise the temperature to 130-140°C, and vacuumize and dehydrate for 90min at the same time;

[0032] (3) Release the vacuum, stop heating and cool down to 90°C, then add 45.36g of 4,4'-diphenylmethane diisocyanate (MDI), catalyst stannous octoate and bis(2,2-morpholine ethyl) ether complex Compound 0.18g, vacuum reaction for 60min at 100°C-110°C, absolute pressure less than 100Pa, to obtain prepolymer;

[0033] (4) Release the vacuum, add 9.54g of pentaerythritol triacryla...

Embodiment 2

[0038] (1) Weigh 44.78g of propylene oxide diol with a molecular weight of 1000, 60.46g of polybutylene adipate diol with a molecular weight of 3000, 53.74g of propylene oxide diol with a molecular weight of 4000, and a total of 2.46g of antioxidants 1076 and 1010 , put it into a 500ml three-neck flask, and heat and stir at 120-130°C for vacuum dehydration for 30min, and the absolute pressure is lower than 100Pa;

[0039] (2) Release the vacuum, then add 73.60g of polyacrylic acid resin while stirring, then raise the temperature to 130-140°C, and vacuumize and dehydrate for 90min at the same time;

[0040] (3) Release the vacuum, stop heating and cool down to 90°C, then add 68.40g of 4,4'-diphenylmethane diisocyanate (MDI), catalyst stannous octoate and bis(2,2-morpholine ethyl) ether complex Compound 0.25g, vacuum reaction at 100°C-110°C, absolute pressure less than 100Pa for 60min to obtain prepolymer;

[0041] (4) Release the vacuum, add 16.01g of pentaerythritol triacryla...

Embodiment 3

[0046] (1) Weigh 37.87g of propylene oxide diol with a molecular weight of 1000, 45.45g of polybutylene adipate diol with a molecular weight of 3000, 53.02g of propylene oxide diol with a molecular weight of 4000, and 2.03g of antioxidants 1076 and 1010 , put it into a 500ml three-neck flask, and heat and stir at 120-130°C for vacuum dehydration for 30min, and the absolute pressure is lower than 100Pa;

[0047] (2) Release the vacuum, then add 71.11g of polyacrylic acid resin while stirring, then raise the temperature to 130-140°C, and vacuumize and dehydrate for 90min at the same time;

[0048] (3) Release the vacuum, stop heating and cool down to 90°C, then add 52.41g of 4,4'-diphenylmethane diisocyanate (MDI), catalyst stannous octoate and bis(2,2-morpholine ethyl) ether complex Compound 0.20g, vacuum reaction at 100°C-110°C, absolute pressure less than 100Pa for 60min to obtain prepolymer;

[0049] (4) Release the vacuum, add 12.72g of dipentaerythritol pentaacrylate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com