Method for preparing microstructured laminating adhesive articles

a technology of adhesive articles and laminating adhesives, applied in the direction of film/foil adhesives, other domestic articles, transportation and packaging, etc., can solve the problems of stress introduced into the adhesive, adversely affecting the optical properties of the adhesive, etc., and achieves low opacity, low haze, and high luminous transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0036] These examples are merely for illustrative purposes only and are not meant to be limiting on the scope of the appended claims. All parts, percentages, ratios, etc. in the examples and the rest of the specification are by weight, unless noted otherwise. Solvents and other reagents used were obtained from Sigma-Aldrich Chemical Company; Milwaukee, Wis. unless otherwise noted.

Table of AbbreviationsAbbreviationor TradeDesignationDescriptionAdhesive3M Optically Clear Adhesive 8141, adhesive thicknessLaminate-125 micrometers (1 mil) between 2 release liners, usedas obtained. Commercially available from 3M Company,St. Paul, MN.Adhesive3M Optically Clear Adhesive 8142, adhesive thicknessLaminate-251 micrometers (2 mils) between 2 release liners,used as obtained. Commercially available from 3MCompany, St. Paul, MN.Adhesive3M Paint Protection Film 84824, adhesive thicknessLaminate-351 micrometers (2 mils) between a paper release linerand a urethane film, used as obtained. Commerciall...

example 1

[0042] For Example 1 a sample of Adhesive Laminate-2 was obtained and one liner was removed and Liner-2 was laminated to the PSA using a laminator. Liner-2 was removed to determine whether the structure had embossed into PSA-1 surface. The embossed surface was placed in contact with a glass plate and pressure was applied with a simple finger rub-down to one half of the sample and the other half of the sample was left untouched. The rubbed portion showed complete wet out as viewed by the eye.

example 2

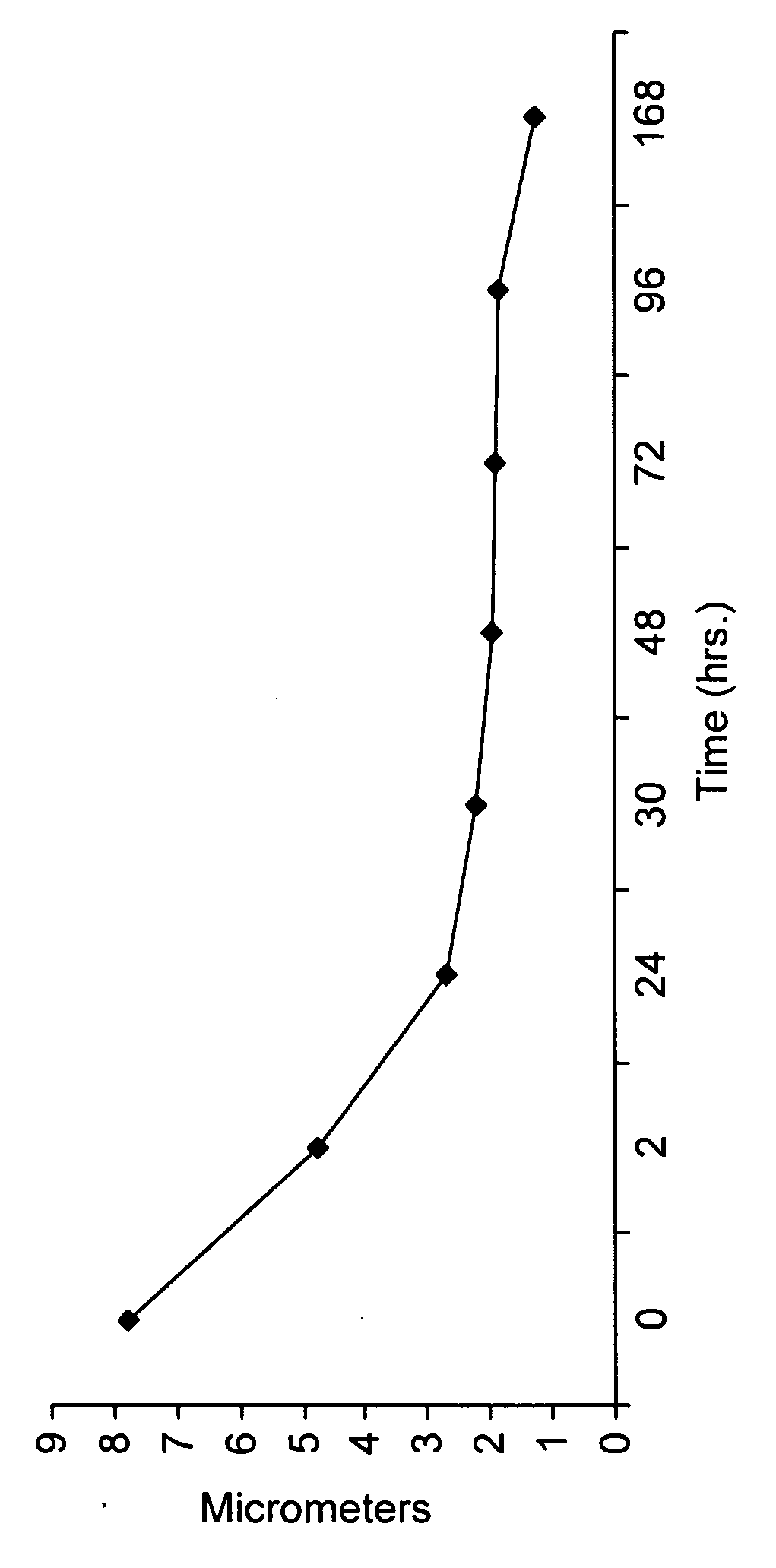

[0043] The same procedure described for Example 1 was followed except that Adhesive Laminate-2 was used. Tape samples were prepared from the sample of Adhesive Laminate-1 by removing one liner, laminating to a 127 micrometer (5 mil) polyethylene terephthalate film and then removing the other liner and laminating Liner-2 to this construction. 180° Peel Adhesion was measured as described in the Test Method above, immediately after adhesion to the glass plate or after a 24 hour dwell on the glass plate. The results are shown in Table 1. Rebound Testing of a tape sample was made. The results are shown in Table 2 and graphically in FIG. 1.

TABLE 1180° Peel Adhesion180° Peel Adhesion AfterExampleInitial (N / dm)24 Hour Dwell (N / dm)C1606024862

[0044]

TABLE 2Elapsed TimeFeature Depth(hours)(Micrometers)07.824.8242.7302.2482.0721.9961.81681.3

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| transmittance | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com