Use of swirl-like adhesive patterns in the formation of absorbent articles

a technology of adhesive patterns and absorbent articles, which is applied in the field of disposable absorbent products, can solve the problems of inability of nozzles to vary the pattern and/or amount of adhesive during operation, and the mechanical stresses which must be resisted by adhesive in a product are rarely uniform, so as to improve the overall properties of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It is to be understood by one of ordinary skill in the art that the present discussion is a description of exemplary embodiments only, and is not intended as limiting the broader aspects of the present invention.

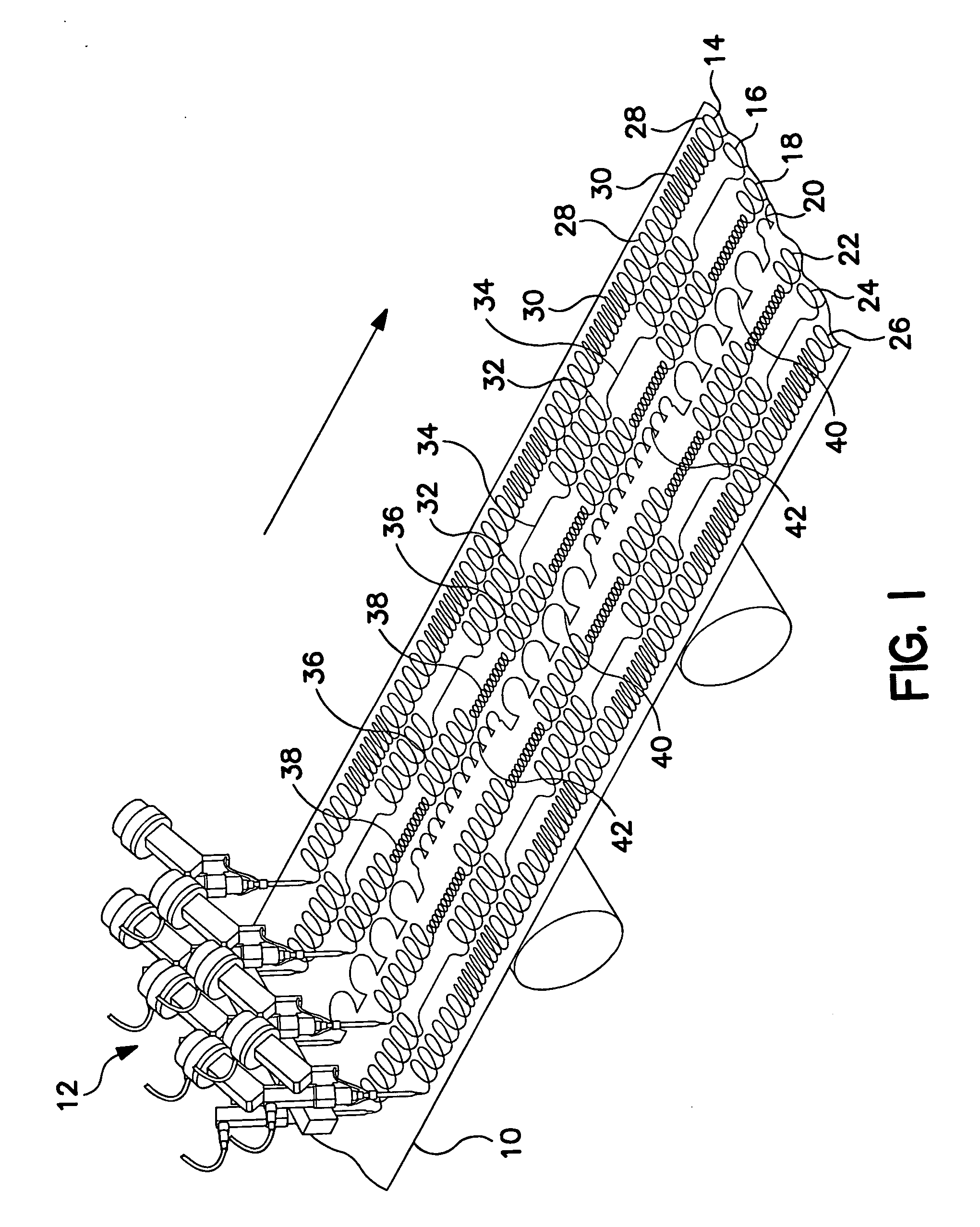

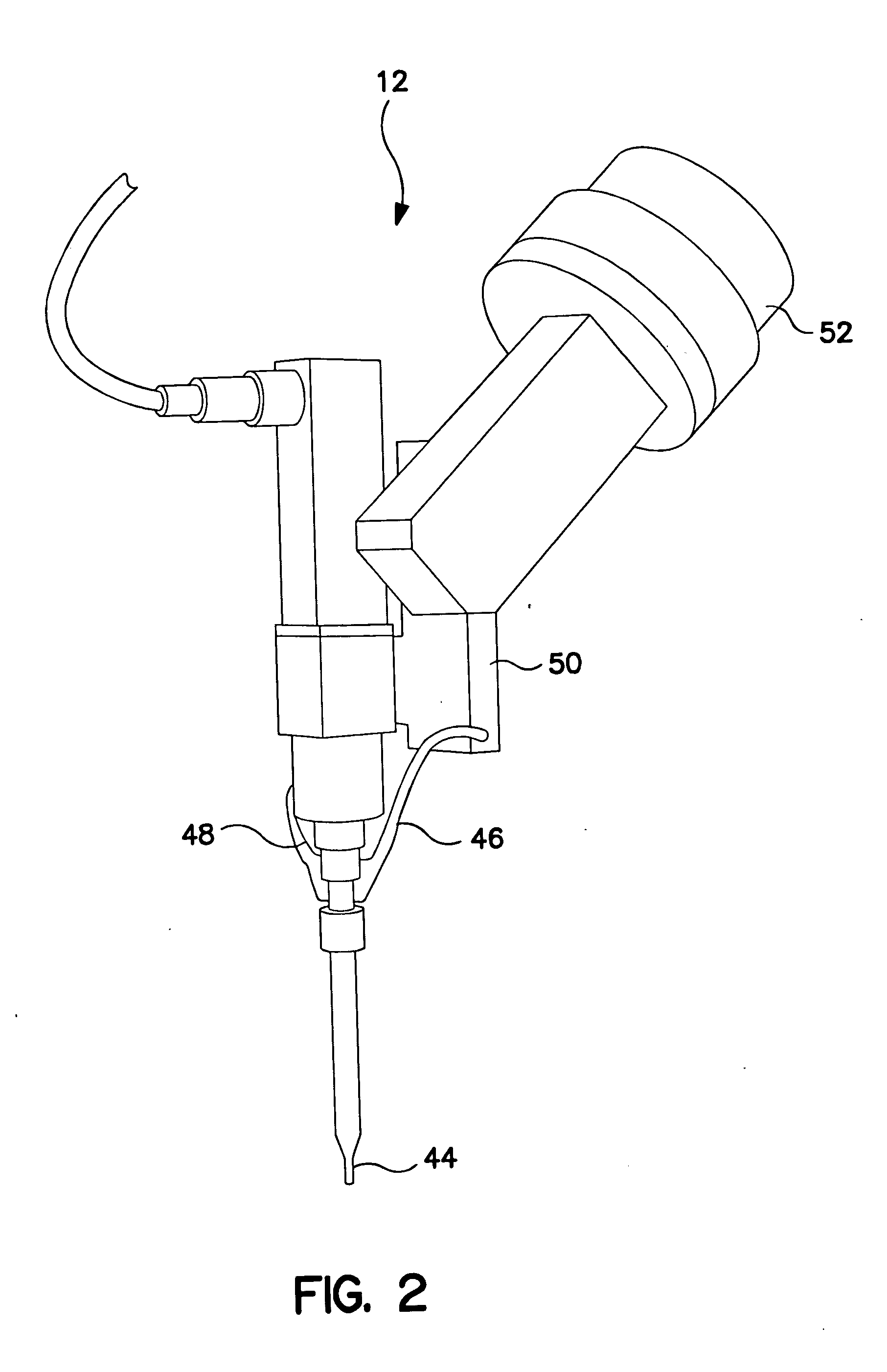

[0020] The present invention is generally directed to a system and process for applying adhesives in between two components in the formation of disposable absorbent products. The disposable absorbent products may be, for instance, diapers, training pants, swim undergarments, sanitary napkins, adult incontinence products, surgical drapes, wound dressings, and the like. Cleaning articles with absorbent components are also contemplated, such as dry or premoistened wipes comprising two or more adhesively joined components, such as a tissue layer joined to a nonwoven web, as disclosed in commonly owned U.S. application Ser. No. 10 / 321,277, “Disposable Scrubby Product,” filed Dec. 17, 2002 by Chen et al., and in commonly owned U.S. application Ser. No. 10 / 036,736, “Sponge-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com