Under roof peel and stick tile underlayment

a peel and stick technology, applied in the field of roof coverings, can solve the problems of liquid based adhesives not always providing good bond strength and long-term durability, adhesives that dry out too quickly, and affect the quality of bonding, so as to achieve easy and hassle-free field application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] As used herein, the term “selvage edge” generally refers to an edge designed for certain sheet good materials, e.g., mineral-surfaced sheets. With mineral surfaced sheets, the surfacing is omitted over a portion of the longitudinal edge of the sheet (e.g., mineral surface cap sheet) in order to obtain better adhesion of the overlapping sheet.

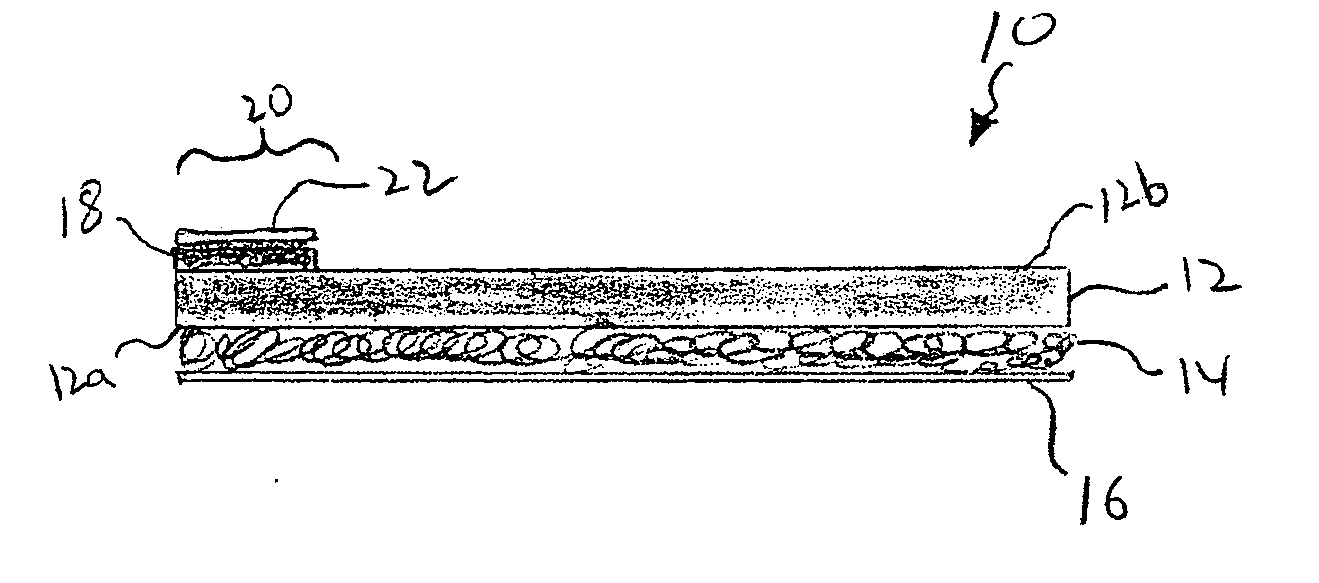

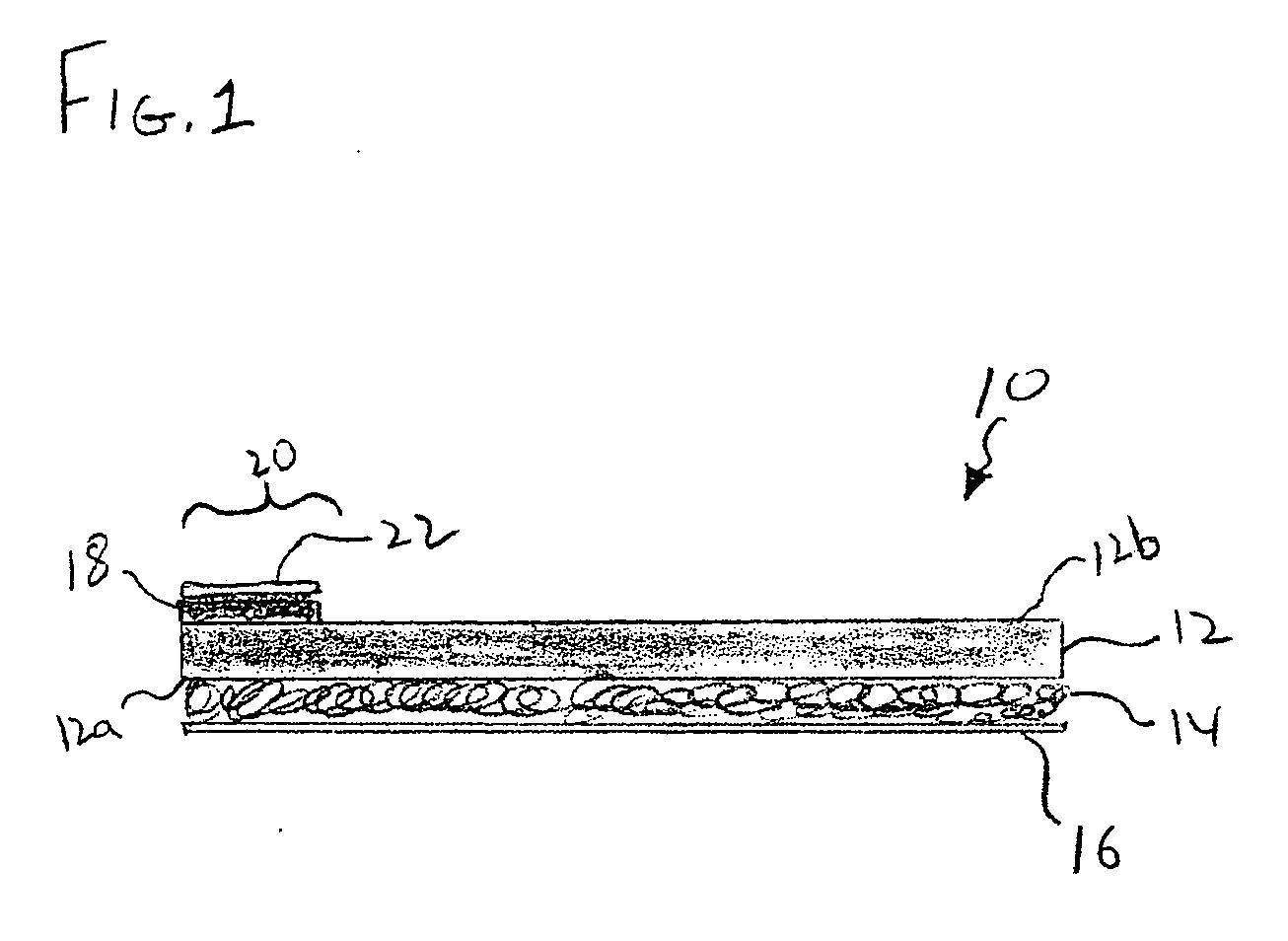

[0013]FIG. 1 is a schematic representation of the layers of the non-asphaltic membrane in accordance with one embodiment of the present invention. In FIG. 1, underlayment sheet 10 includes substrate 12 having a deck side 12a, which is the lower surface of substrate 12 that is applied on a roof substrate (not shown), and a weather side 12b on the opposite side of membrane 12, and which is the upper surface of substrate 12 that is exposed to the environment when deck side 12a of membrane 12 is applied to a roof substrate. An adhesive layer 14 is coated on deck side 12a of membrane 12. Adhesive layer 14 is preferably a self-stick compound. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com