Flexible substrate structure and method of fabricating the same

a flexible substrate and substrate technology, applied in the direction of transportation and packaging, coatings, chemistry apparatuses and processes, etc., can solve the problems of high fabrication cost and consequent peeling problems, and achieve the effect of promoting yield rate and quality of flexible substrate structure and reducing fabrication cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]To provide a better understanding of the presented invention for one skilled in the art, preferred embodiments will be detailed as follows. The preferred embodiments of the present invention are illustrated in the accompanying drawings with numbered elements to elaborate the contents and effects to be achieved.

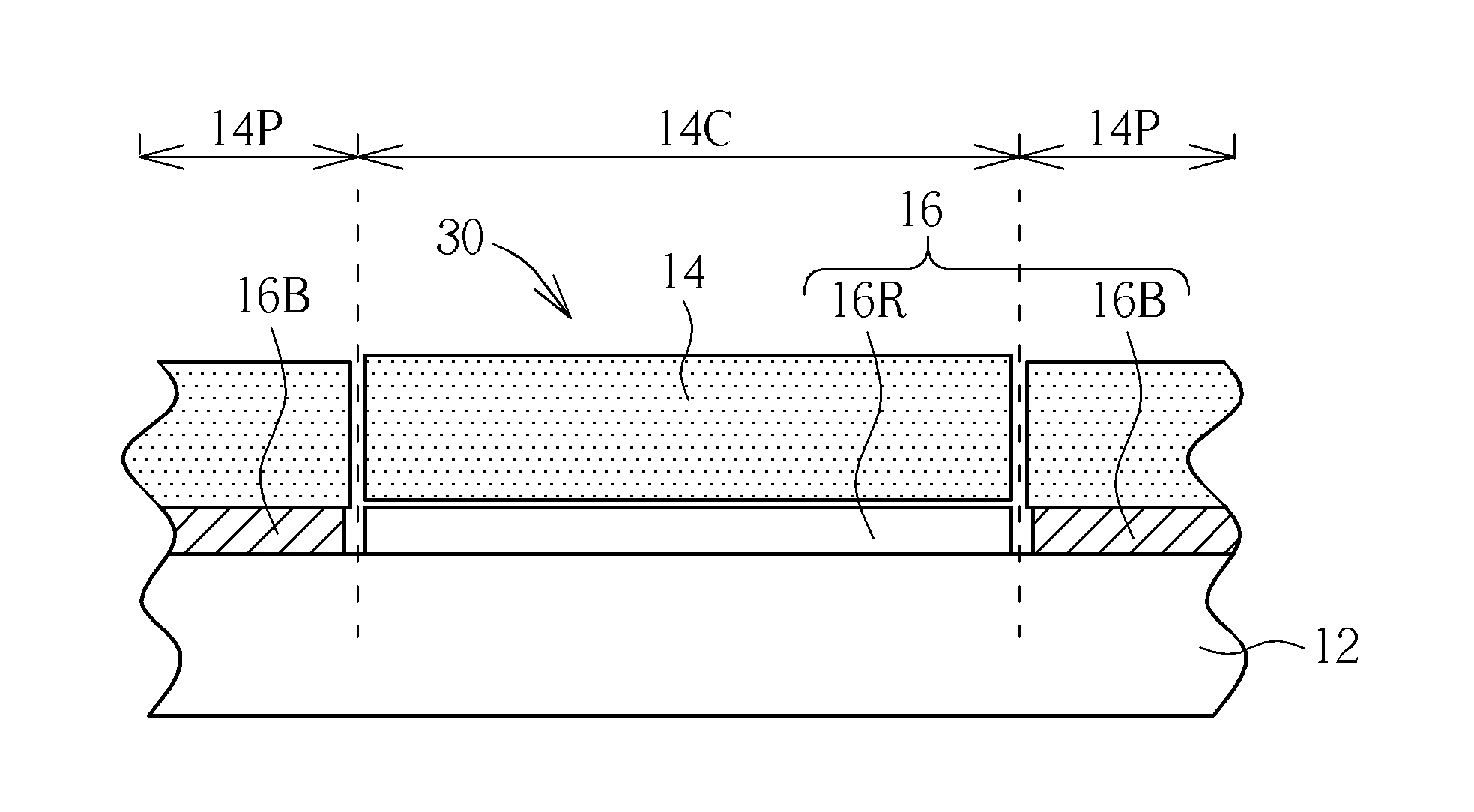

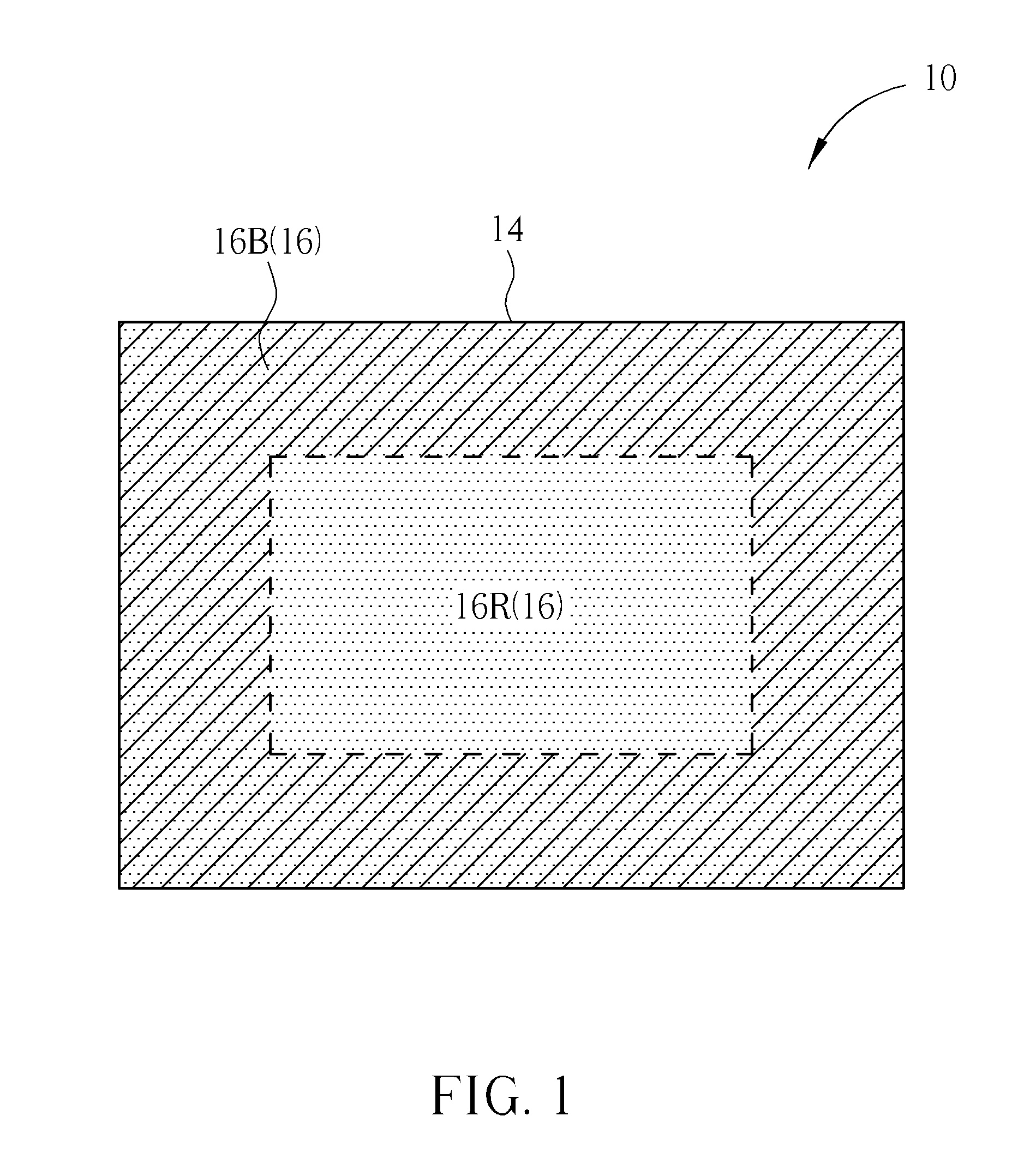

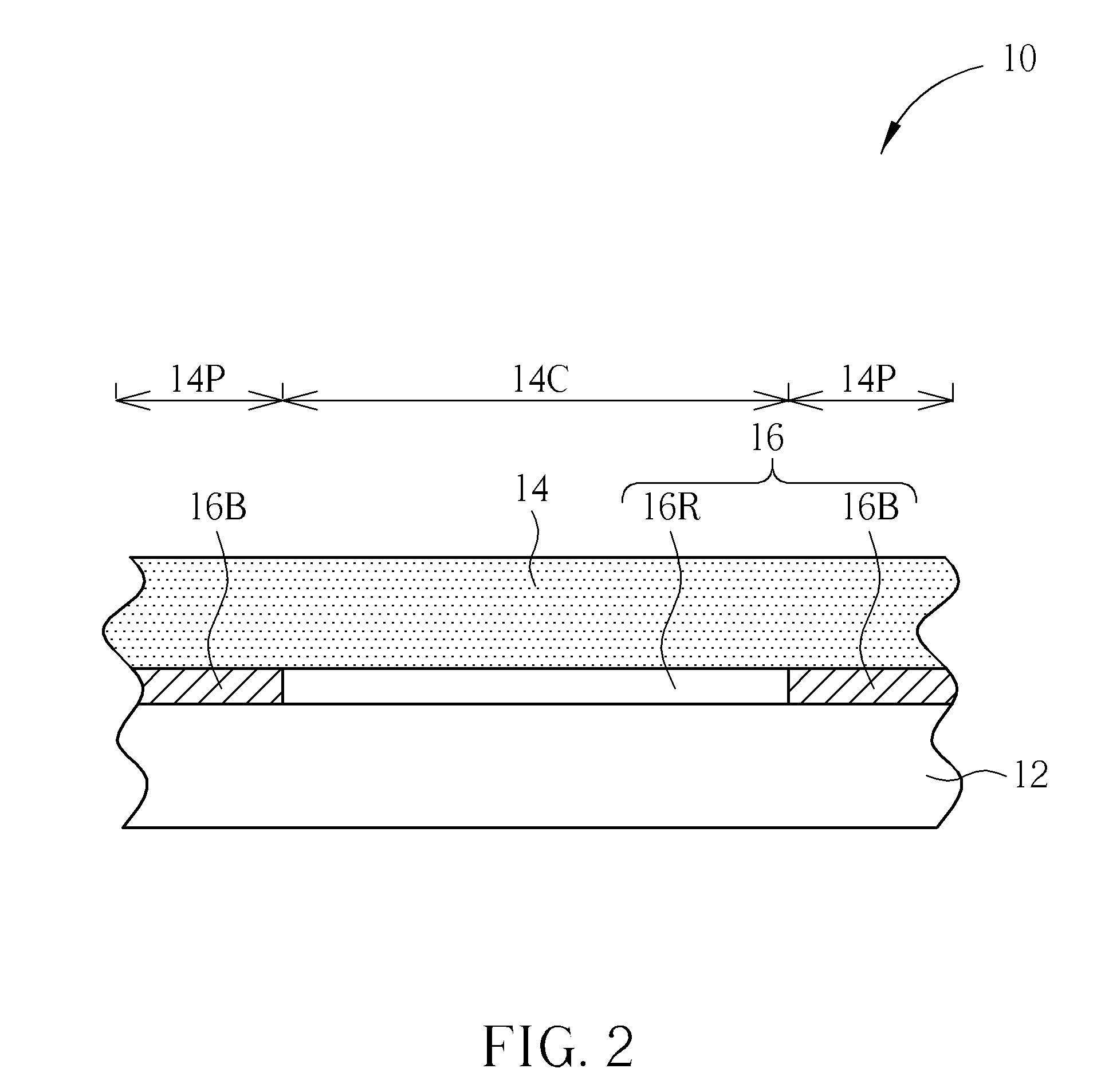

[0015]Please refer to FIG. 1 and FIG. 2, which schematically illustrate a flexible substrate structure according to a preferred embodiment of the present invention. FIG. 1 illustrates a top view of the flexible substrate, and FIG. 2 illustrates a cross-sectional view of the flexible substrate structure. To distinguish features of the flexible substrate structure of the present invention, some components are not shown in FIG. 1. As shown in FIG. 1 and FIG. 2, the flexible substrate structure 10 according to this embodiment includes a supporting carrier 12, a flexible substrate 14, and a release layer 16. Compared to the flexible substrate 14, the supporting carrier 12 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| exposure time | aaaaa | aaaaa |

| exposure time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com