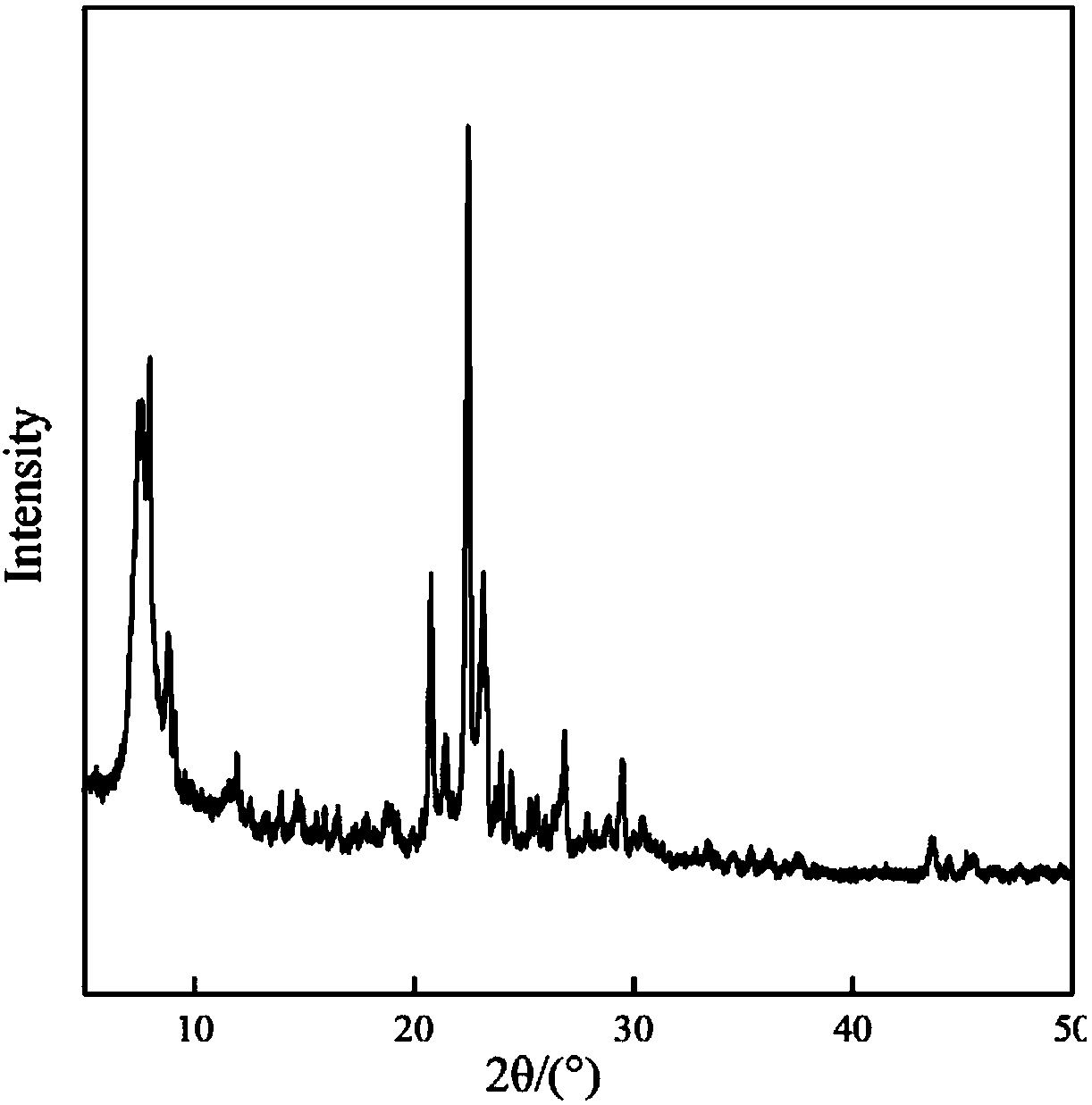

Beta/ZSM-12 intergrowth zeolite molecular sieve and preparation method thereof

A technology of symbiotic molecular sieves and seed crystals, which is applied in the direction of ZSM-12 crystalline aluminum silicate zeolite, molecular sieve catalysts, molecular sieves and alkali exchange compounds, can solve the problems of high cost, single shape of symbiotic molecular sieves, complex preparation, etc., and achieve Reduced emissions, simple process, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Raw material configuration: Take 5.2g of tetraethylammonium bromide (0.025mol, equivalent to 0.3 times of coarse-pore silica gel) and add it to 28.71g of water (1.595mol, equivalent to 20 times of coarse-pore silica gel), and add to the solution 3.37g of ammonia water (0.0525mol, equivalent to 0.64 times of coarse-pore silica gel) was added dropwise, followed by 0.61g of sodium hydroxide (0.015mol, equivalent to 0.18 times of coarse-pore silica gel) and 0.42g of potassium hydroxide (0.0063mol, Equivalent to 0.077 times of coarse-porous silica gel), stir for 5-10min to dissolve and add 0.31g pseudo-boehmite (0.002mol Al 2 o 3 , equivalent to 0.025 times of coarse-pore silica gel), continue to stir for 10-80min until the solution is clear, slowly add coarse-pore silica gel 5g (0.082mol) and stir at a constant speed for 3h.

[0044] Introduction of seed crystals: the seed crystals are Beta zeolite with a silicon-aluminum ratio of 140, the amount of which is 0.5 g, whi...

Embodiment 2

[0051] (1) Raw material configuration: Take 5.2g of tetraethylammonium bromide (0.025mol, equivalent to 0.3 times of coarse-pore silica gel) and add it to 28.75g of water (1.597mol, equivalent to 20 times of coarse-pore silica gel), and add to the solution 3.15g of ammonia water (0.049mol, equivalent to 0.60 times of coarse-pore silica gel) was added dropwise, followed by 0.48g of sodium hydroxide (0.011mol, equivalent to 0.13 times of coarse-pore silica gel), and 0.33g of sodium bromide (0.003mol , equivalent to 0.037 times of coarse-pore silica gel) to adjust the sodium ion content and 1.13g potassium hydroxide (0.017mol, equivalent to 0.21 times of coarse-pore silica gel), stirring for 5-10min to dissolve and then adding 0.31g of pseudo-boehmite ( 0.002mol Al 2 o 3 , equivalent to 0.025 times of coarse-pore silica gel), continue to stir for 10-80min until the solution is clear, slowly add coarse-pore silica gel 5g (0.082mol) and stir at a constant speed for 3h.

[0052] I...

Embodiment 3

[0057] (1) Raw material configuration: Take 5.2g of tetraethylammonium bromide (0.025mol, equivalent to 0.3 times of coarse-pore silica gel) and add it to 28.77g of water (1.598mol, equivalent to 20 times of coarse-pore silica gel), and then add 0.75g sodium hydroxide (0.018mol, equivalent to 0.22 times of coarse-pored silica gel) and 0.51g potassium hydroxide (0.0077mol, equivalent to 0.094 times of coarse-pored silica gel), and 3.07g of ammonia water (0.048mol, equivalent to 0.094 times of coarse-pored silica gel) was added dropwise to the solution. Equivalent to 0.59 times that of coarse-porous silica gel), stir for 5-80min to dissolve and add 0.31g pseudo-boehmite (0.002mol Al 2 o 3 , equivalent to 0.025 times that of coarse-pore silica gel), continue to stir for 10-50min until the solution is clear, slowly add coarse-pore silica gel 5g (0.082mol) and stir at a constant speed for 3h.

[0058] Introduction of seed crystals: the seed crystals are Beta zeolite with a silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com