Method for synthesis of high silicon zeolite molecular sieve with universal gel

A high-silica zeolite and molecular sieve technology, which is applied in the directions of crystalline aluminosilicate zeolite, iron conglomerate crystalline aluminosilicate zeolite, borane silicone crystalline aluminosilicate zeolite, etc., can solve the serious discharge of waste liquid and exhaust gas. , high synthesis cost, high toxicity and other problems, to achieve the effect of reducing loss, good crystallinity and purity, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Crystallization of universal precursor at 160°C

[0027] First, the 8.12gH 2 O (deionized water, the same below) and 0.092g of aluminum sulfate are mixed uniformly, then 0.38g of NaOH is added thereto, and then 3.32g of silica sol (silicon dioxide content 30.5%, the same below) is added under stirring, and the stirring is continued until the solution becomes uniform, then add the reaction raw materials into a polytetrafluoroethylene stainless steel reactor, crystallize at 160°C for 24 hours, filter the product with suction, and dry it to obtain the product.

[0028] The ratio of the reaction raw materials is as follows: SiO 2 :0.0083Al 2 o 3 :0.28Na 2 O:35H 2 o

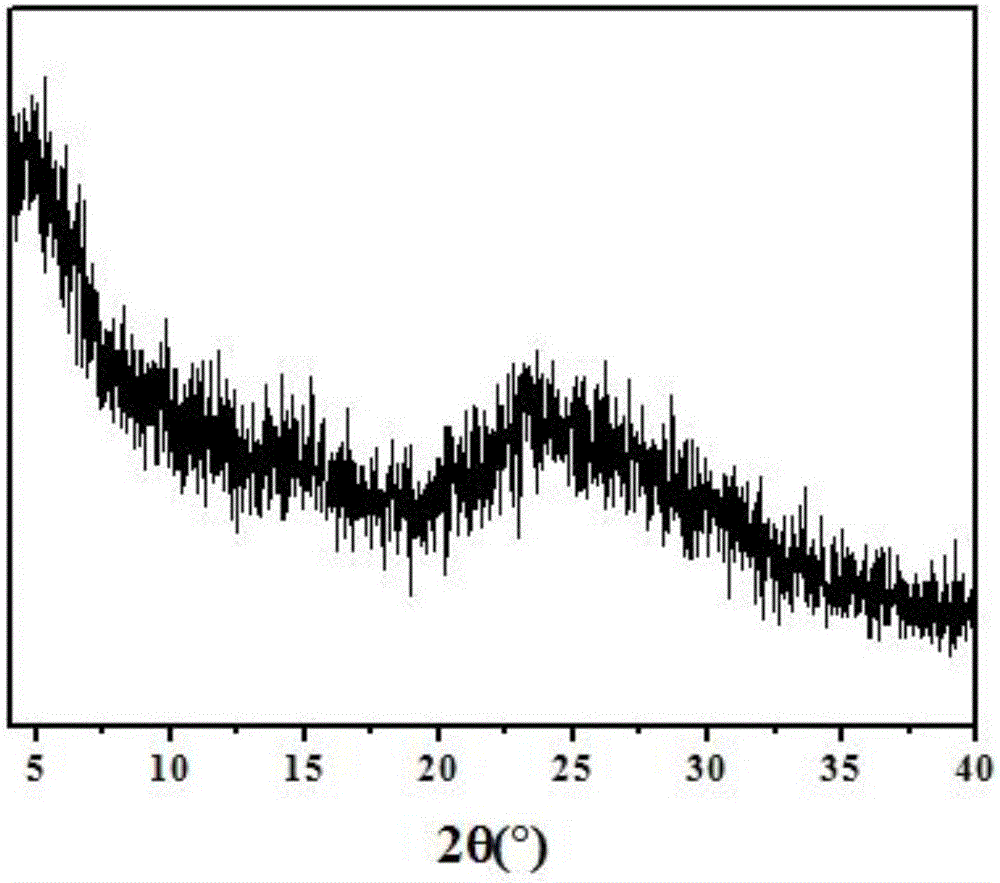

[0029] Its structure is amorphous by X-ray diffraction analysis. attached figure 1 It is the XRD spectrum of the universal precursor after crystallization at 160°C.

Embodiment 2

[0030] Example 2: Crystallization of the universal precursor with the addition of ZSM-5 zeolite molecular sieve seeds at 160°C

[0031] 8.12gH 2 O and 0.092g aluminum sulfate are mixed uniformly, then add 0.38g NaOH, then add 3.32g silica sol under stirring, continue to stir until the solution becomes uniform, add ZSM-5 molecular sieve accounting for 10% of the mass of the silicon source as a seed crystal, and stir After uniformity, the gel was added into a polytetrafluoroethylene stainless steel reactor, and crystallized in an oven at 160°C for 8 hours. The product was filtered with suction and dried.

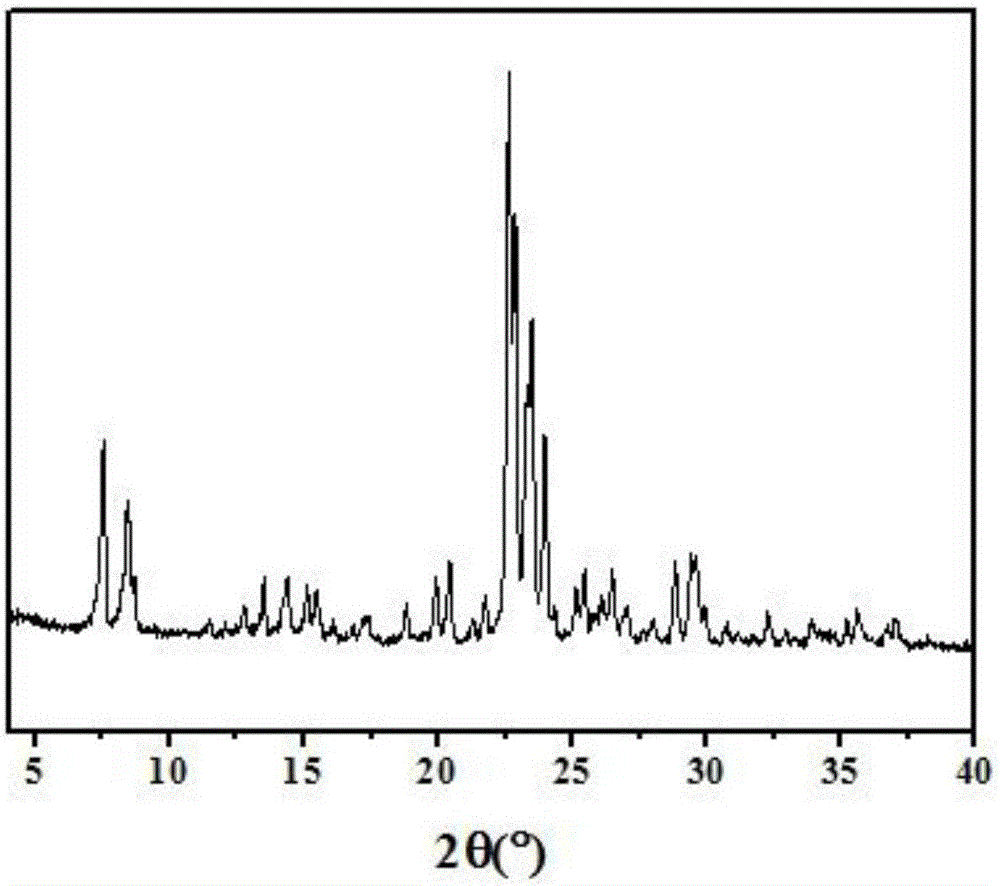

[0032] attached figure 2 The XRD spectrum of the ZSM-5 zeolite molecular sieve prepared by the seed crystal method shows that the product has a typical ZSM-5 zeolite molecular sieve structure, and the sample has a high degree of crystallinity.

Embodiment 3

[0033] Example 3: Crystallization of the universal precursor with the addition of MOR zeolite molecular sieve seeds at 160°C

[0034] 8.12gH 2 O and 0.092g of aluminum sulfate are mixed evenly, and then 0.38g of NaOH is added to it, and then 3.32g of silica sol is added under stirring, and the stirring is continued until the solution becomes uniform, and 10% of the mass of the silicon source is added as a MOR molecular sieve as a seed crystal, and after stirring , put the gel into a polytetrafluoroethylene stainless steel reactor, and crystallize it in an oven at 160°C for 12h. The product was filtered with suction and dried.

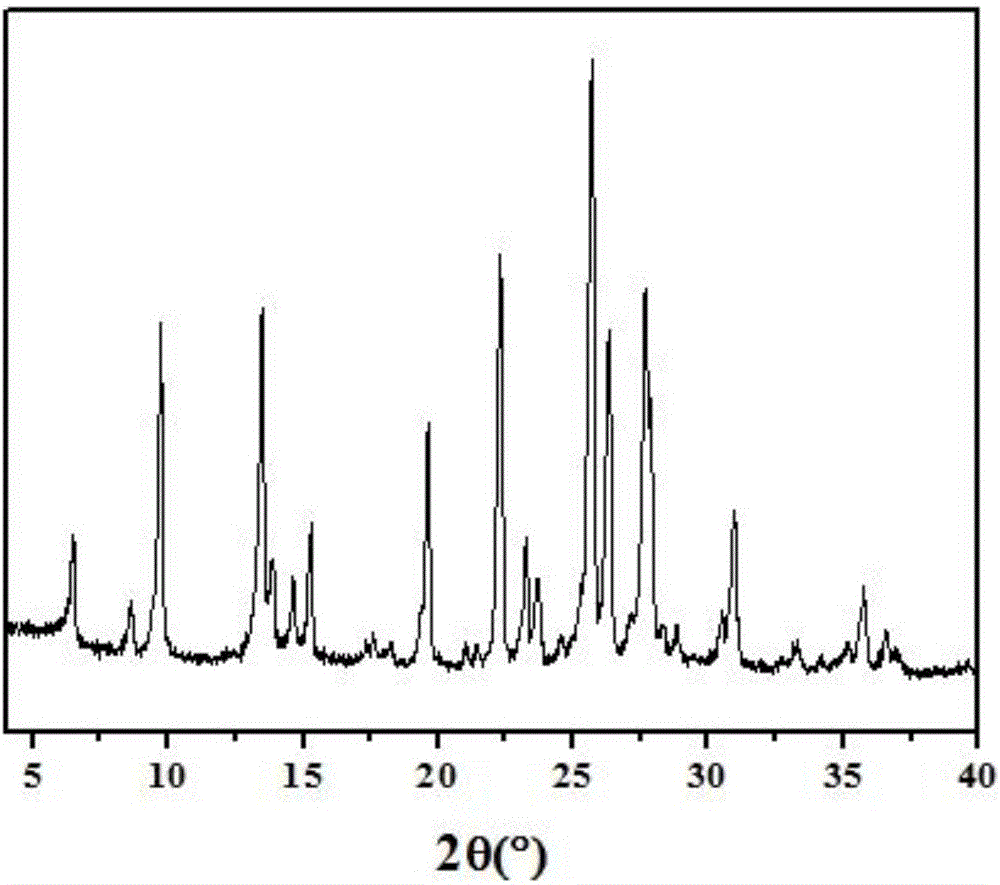

[0035] attached image 3 The XRD spectrum of the MOR zeolite molecular sieve prepared by the seed crystal method, it can be seen from the spectrum that the product has a typical MOR zeolite molecular sieve structure, and the sample has a high degree of crystallinity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com