ZSM-12 molecular sieve with special crystal orientation as well as preparation method thereof

A technology of crystal orientation and molecular sieve, applied in the direction of ZSM-12 crystalline aluminosilicate zeolite, organic chemistry, crystalline aluminosilicate zeolite, etc., can solve the problem of inability to control the crystal orientation of ZSM-12 molecular sieve, and improve the conversion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Stir 3.283ml of water glass and 11.866ml of water first, then add 4.802ml of 23.08% MTEABr solution and stir evenly, then add 2.779ml of 7.41% nonahydrate aluminum nitrate solution, and add 0.271ml of 30% sulfuric acid under strong stirring solution, forming a mixture with the following molar composition: SiO2 / Al 2 o 3 =60, OH / SiO 2 =0.3, Na 2 O / (MTEA) 2 O=1.5, H 2 O / OH=225.

[0027] 2. Pour the sample into a polytetrafluoroethylene-lined reactor and crystallize at 160 oC for 156 hours.

[0028] 3. The above product is cooled, filtered, washed and dried to obtain a product sample.

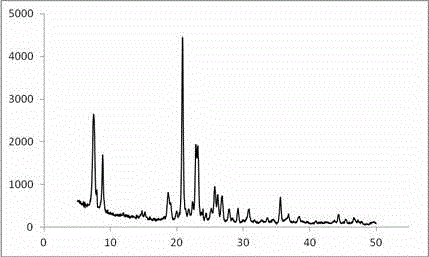

[0029] The results of the XRD pattern of the product are shown in the appendix of the instruction manual. figure 1 : Its XRD pattern shows ZSM-12 topological structure, and the relative intensity of characteristic peaks is B / A=1.7, C / A=0.8.

[0030]

Embodiment 2

[0032] 1. First, stir 4.894ml of 40% TEABr solution and 3.709ml of water evenly, add 0.14g of sodium metaaluminate and stir until the solid dissolves, then add 13.461ml of 30% silica sol, and stir well to form a mixture with the following molar composition: SiO 2 / Al 2 o 3 =120, OH / SiO 2 =0.1, TEA + / SiO 2 =0.125,H 2 O / SiO 2 =13.

[0033] 2. Pour the sample into a polytetrafluoroethylene-lined reactor and crystallize at 160 oC for 120 hours.

[0034] 3. The above product is cooled, filtered, washed and dried to obtain a product sample.

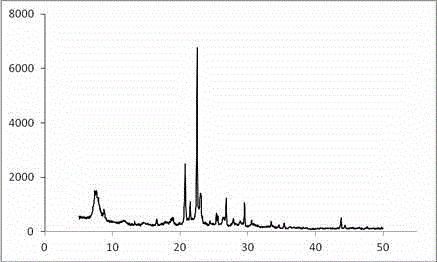

[0035] The XRD of the product is shown in the attached manual figure 2 : Its XRD pattern shows ZSM-12 topological structure, and the relative intensity of characteristic peaks is B / A=1.5, C / A=4.5.

[0036]

Embodiment 3

[0038] 1. First, stir 10.380 ml of 25% TEAOH solution and 0.485 ml of water evenly, add 0.128 g of sodium metaaluminate and stir until the solid dissolves, then add 12.076 ml of 30% silica sol, and stir well to form the following mixture with molar composition: SiO 2 / Al 2 o 3 =116, OH / SiO 2 =0.245,TEA + / SiO 2 =0.245,H 2 O / SiO 2 =14.

[0039] 2. Pour the sample into a polytetrafluoroethylene-lined reactor and crystallize at 160 oC for 132 hours.

[0040] 3. The above product is cooled, filtered, washed and dried to obtain a product sample.

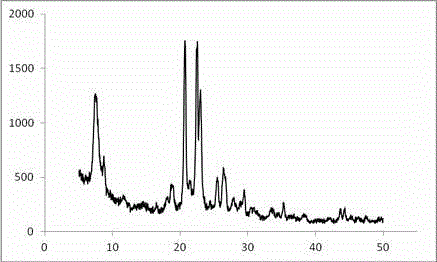

[0041] The XRD of the product is shown in the attached manual image 3 : Its XRD pattern shows ZSM-12 topological structure, and the relative intensity of characteristic peaks is B / A=1.4, C / A=1.4.

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com