Multi-level pore channel molecular sieve preparation method

A microporous molecular sieve and molecular sieve technology are applied in the field of preparation of multi-stage porous molecular sieves, which can solve the problems of increased cost, complicated operation process, strong corrosiveness and the like, and achieve the effect of simplifying the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take Beta molecular sieve with Si / Al=19, mix it with 10wt.% urea solution according to the ratio of 1g:100mL, and stir and react for 5h under the condition of back distillation. Suction filtration, washing with deionized water, drying, 550 o C roasting for 5 hours to obtain micro-mesoporous molecular sieves, that is, multi-level channel Beta molecular sieves.

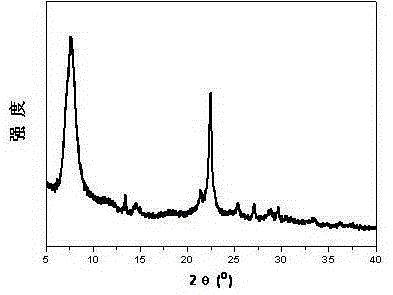

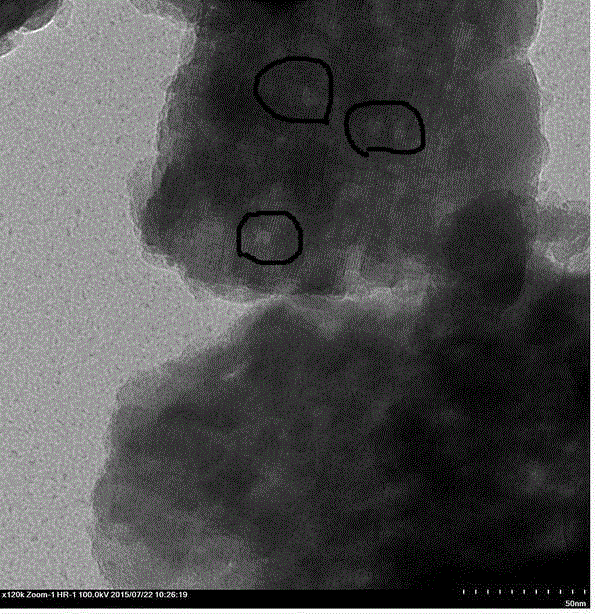

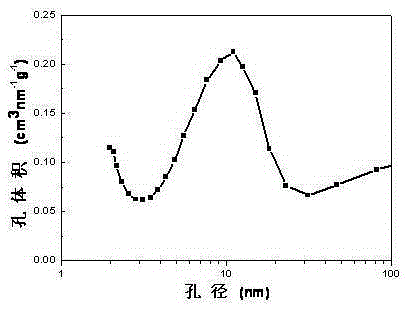

[0020] The X-ray diffraction pattern (XRD) of the obtained sample is shown in the attached figure 1 , the TEM image is shown in the appendix figure 2 , the mesopore size distribution is shown in the attached image 3 , NH 3 -TPD diagram see attached Figure 4 . The specific surface area of the obtained sample is 452m 2 / g, total pore volume 0.34cm 3 .g -1 , mesopore volume 0.18cm 3 .g -1 , the BJH pore size distribution of the mesopores is 3-22nm, and the mesopore diameter of the concentrated distribution is 11nm.

Embodiment 2

[0022] Take Beta molecular sieve with Si / Al=55, mix it with 20wt.% urea solution according to the ratio of 1g:20mL, and stir and react for 10h under the condition of back distillation. Suction filtration, washing with deionized water, drying, 550 o C roasting 5h. Finally, a micro-mesoporous molecular sieve is obtained. The specific surface area of the obtained sample is 438m 2 / g, total pore volume 0.37cm 3 .g -1 , mesopore volume 0.22cm 3 .g -1 , the BJH pore size distribution of the mesoporous is 4-32nm, and the mesopore pore size of the concentrated distribution is 14nm.

Embodiment 3

[0025] Get the Beta molecular sieve of Si / Al=19, mix with 10wt.% urea solution according to the ratio of 1g:100mL, at 80 o C stirred the reaction for 5h. Suction filtration, washing with deionized water, drying, 550 o C roasting 5h. Finally, a micro-mesoporous molecular sieve is obtained. The specific surface area of the obtained sample is 473m 2 / g, total pore volume 0.33cm 3 .g -1 , mesopore volume 0.17cm 3 .g -1 , The BJH pore size distribution of the mesoporous is 3-18nm, and the pore size of the concentrated mesopore is 8nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com