A kind of preparation method of fe-zsm-5 molecular sieve with high iron content

A technology of fe-zsm-5 and molecular sieves, applied in the field of molecular sieves, can solve the problems of low catalytic activity of molecular sieves, environmental pollution, defects in the crystal skeleton of Fe-ZSM-5 molecular sieves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

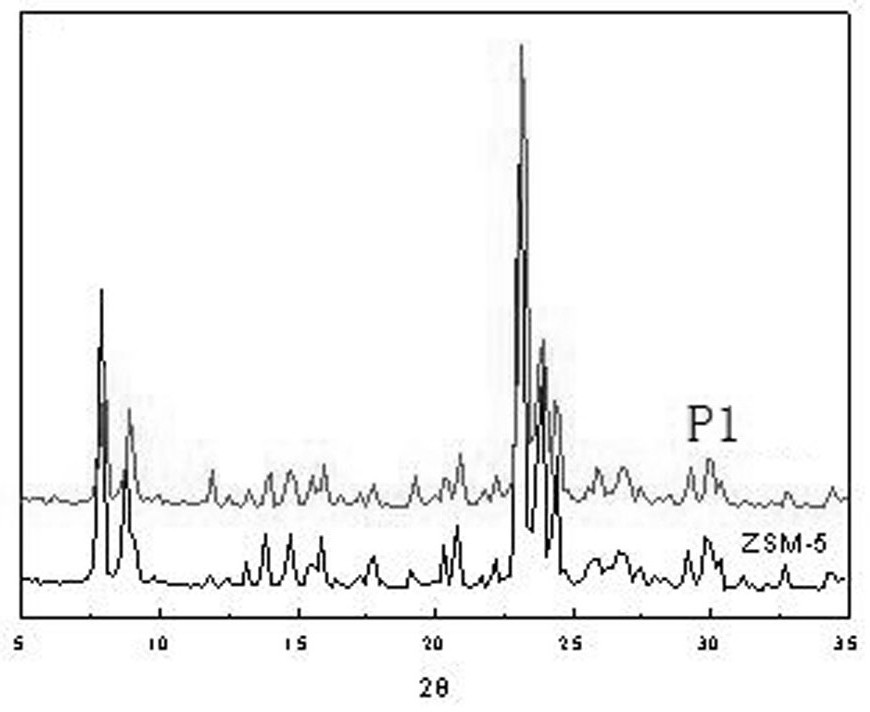

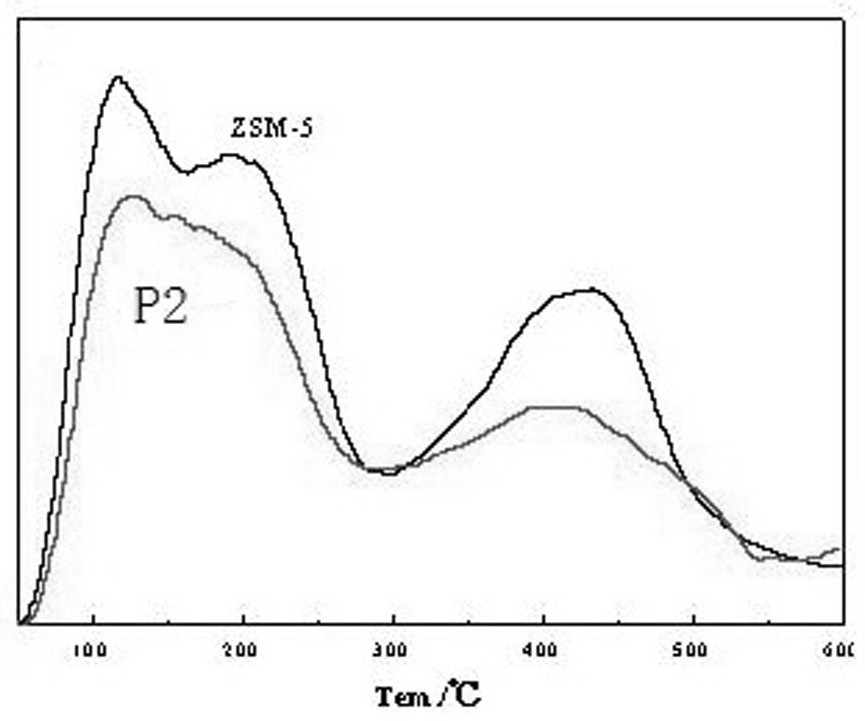

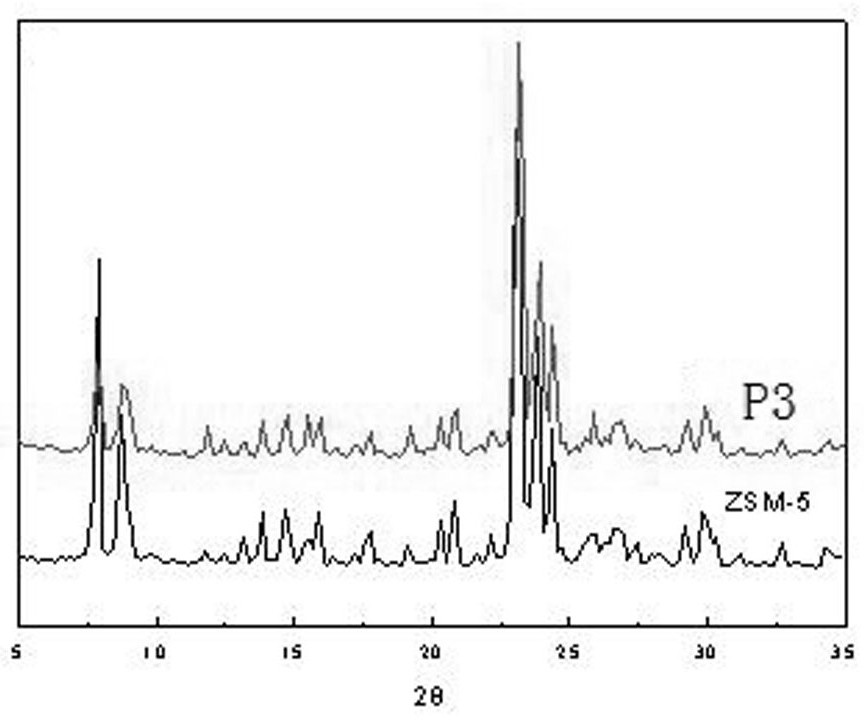

Image

Examples

preparation example Construction

[0034] A preparation method of Fe-ZSM-5 molecular sieve with high iron content, comprising the following steps:

[0035] ① Dissolve aluminum source and iron source in water, and age at 70-90°C for 2-3 hours to obtain solution B; the ratio of aluminum source, iron source and water is based on the molar ratio of aluminum ion, iron ion and water Calculated as 1:0.1~1:100~200; the aluminum source is aluminum sulfate, aluminum chloride or aluminum nitrate; the iron source is ferrous sulfate, ferrous chloride, ferric sulfate, ferric chloride or ferric nitrate ;

[0036] ②Beat the silicon source, alkali source and seed crystal in water evenly to obtain the A solution; the components in the A solution and step ① are Al 2 o3 Calculate the molar ratio of aluminum source to SiO 2 :Na 2 O: A1 2 o 3 :H 2 O=40~120: 8~12: 1: 200~1900; the quality of seed crystal is 0.2~2 times of the aluminum source quality in step 1; described silicon source is white carbon black, silica gel and / or wa...

Embodiment 1

[0056] A preparation method of Fe-ZSM-5 molecular sieve with high iron content, comprising the following steps:

[0057] ① Dissolve 34.24kg of aluminum sulfate and 4.0kg of iron sulfate in 360kg of water, and age at 70°C for 2 hours to obtain solution B;

[0058] ②Beat 240kg of white carbon black, 64kg of sodium hydroxide and 6.85kg of seed crystals in 360kg of water to obtain A solution;

[0059] ③Under stirring, drop the B solution obtained in step ① into the A solution obtained in step ②, heat up to 85°C for pre-crystallization for 2 hours, then heat up to 160°C for 5 hours to obtain a slurry, and the stirring speed is 80 rpm / Minute;

[0060] 4. step 3. gained slurry is filtered, and filter cake is washed with the water of 5 times of weight, then adds in the acid solution of 5 times of weight to exchange and remove sodium ion, suction filtration washing, obtains low-sodium Fe-ZSM-5 molecular sieve; Wherein acid solution is 10% ammonium sulfate solution by mass fraction; ...

Embodiment 2

[0063] A preparation method of Fe-ZSM-5 molecular sieve with high iron content, comprising the following steps:

[0064] ①Dissolve 13.33kg of aluminum chloride and 12.68kg of ferrous chloride in 360kg of water, and age at 90°C for 3 hours to obtain solution B;

[0065] 2. Water glass (modulus 3.2) 852.9kg, white carbon black 625.50kg and seed crystal 26.66kg are evenly beaten in water 1710kg to obtain A solution;

[0066] ③Under stirring, drop the B solution obtained in step ① into the A solution obtained in step ②, heat up to 95°C for pre-crystallization for 3 hours, then heat up to 200°C for 48 hours to obtain a slurry, and the stirring speed is 200 rpm / Minute;

[0067] 4. step 3. gained slurry is filtered, and filter cake is washed with the water of 10 times of weight, then adds the acidic solution exchange of 10 times of weight to remove sodium ion, suction filtration washing, obtains low-sodium Fe-ZSM-5 molecular sieve; Wherein acidic solution is quality Fraction 15% a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com