High activity small crystal zsm-12

A ZSM-12, porous crystallization technology, applied in the direction of ZSM-12 crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1 (comparison)

[0064] A mixture was prepared from 306 g water, 83 g 50% tetraethylammonium bromide (TEABr), 64.3 g UltrasilPM, 1.55 g aluminum hydroxide and 15.8 g 50% sodium hydroxide solution. This mixture has the following molar composition:

[0065] SiO 2 / Al 2 o 3 =100

[0066] h 2 O / SiO 2 =20

[0067] Oh - / SiO 2 =0.2

[0068] Na + / SiO 2 =0.2

[0069] TEABr / SiO 2 =0.2

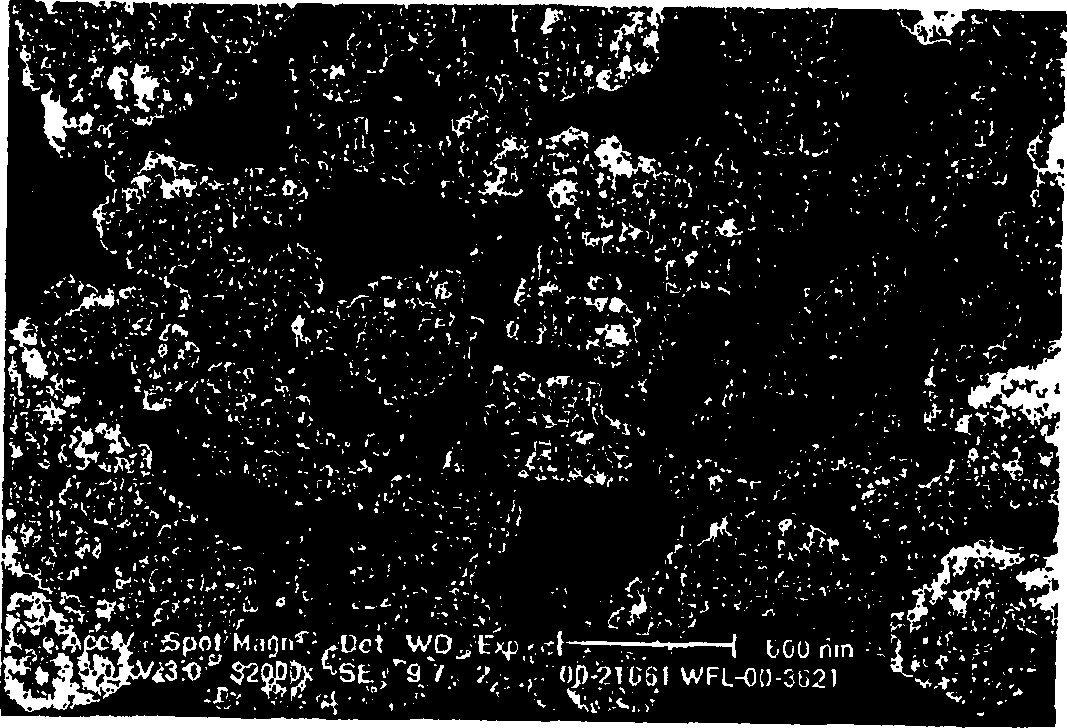

[0070] The mixture was reacted in a 600 ml autoclave at 285°F (140°C) for 168 hours at a stirring speed of 150 RPM. The product was filtered, washed with deionized water (DI) and dried at 250°F (120°C). The XRD pattern of the as-synthesized material shows a typical pure phase of the ZSM-12 topology. The SEM photographs of the as-synthesized materials are shown in figure 1 , and show that the material consists of agglomerates of small crystals (average crystal size approximately 0.05 microns).

[0071] The synthesized crystals were converted to the hydrogen form by ...

Embodiment 2

[0072]Embodiment 2 (comparison)

[0073] The same reactants and reaction procedure as in Example 1 were used except that methyltriethylammonium bromide (MTEA) was used as the directing agent.

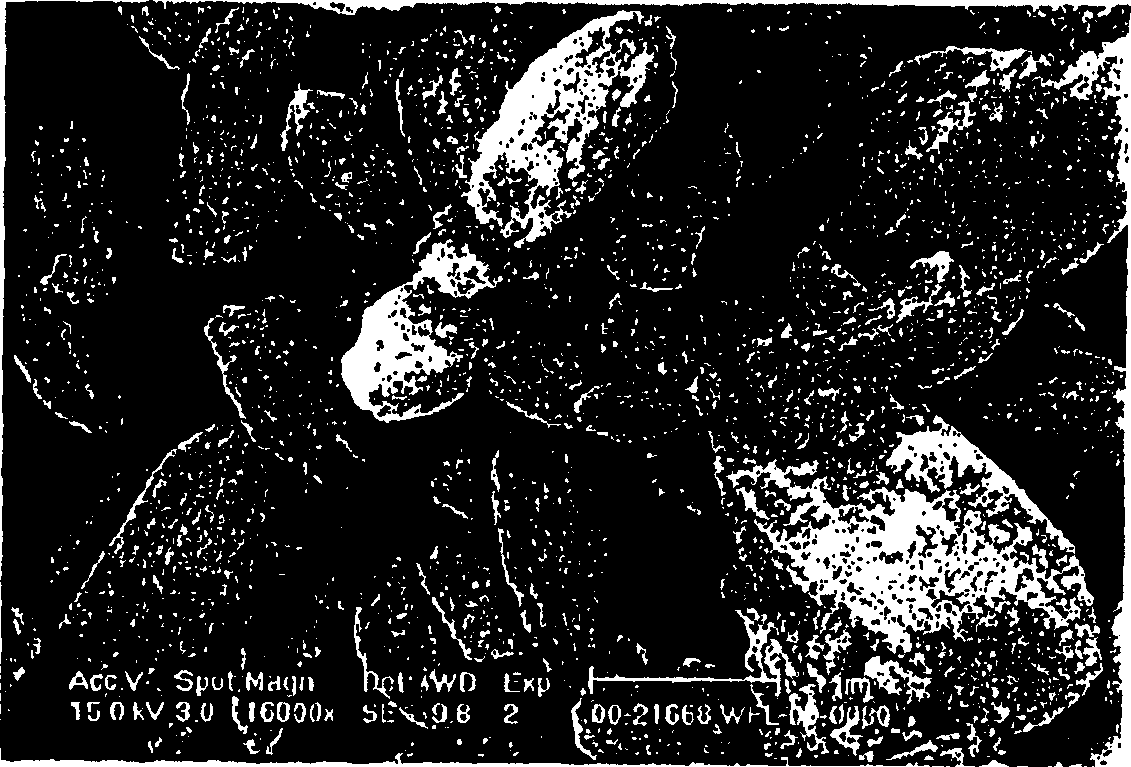

[0074] The SEM photographs of the as-synthesized materials are shown in figure 2 , and showed that the material consisted of agglomerates of rice-like crystals (average crystal size 1-5 microns).

[0075] The synthesized crystals were converted to the hydrogen form by two ion exchanges with ammonium nitrate solution at room temperature, followed by drying at 250°F (120°C) and calcination at 1000°F (540°C) for 6 hours. The resulting ZSM-12 crystals have SiO 2 / Al 2 o 3 Molar ratio of 116, alpha value of 92, and D / r for 1,3,5-trimethylbenzene (mesitylene) at 100°C 2 The parameter is 19×10 -6 .

Embodiment 3

[0076] Embodiment 3 (comparison)

[0077] A mixture was prepared from 348 g water, 30 g methyltriethylammonium chloride (MTEACl), 64.3 g UltrasilPM, 2.33 g aluminum hydroxide and 17.4 g 50% sodium hydroxide solution. This mixture has the following molar composition:

[0078] SiO 2 / Al 2 o 3 =67

[0079] h 2 O / SiO 2 =20

[0080] Oh - / SiO 2 =0.22

[0081] Na + / SiO 2 =0.22

[0082] MTEACl / SiO 2 =0.2

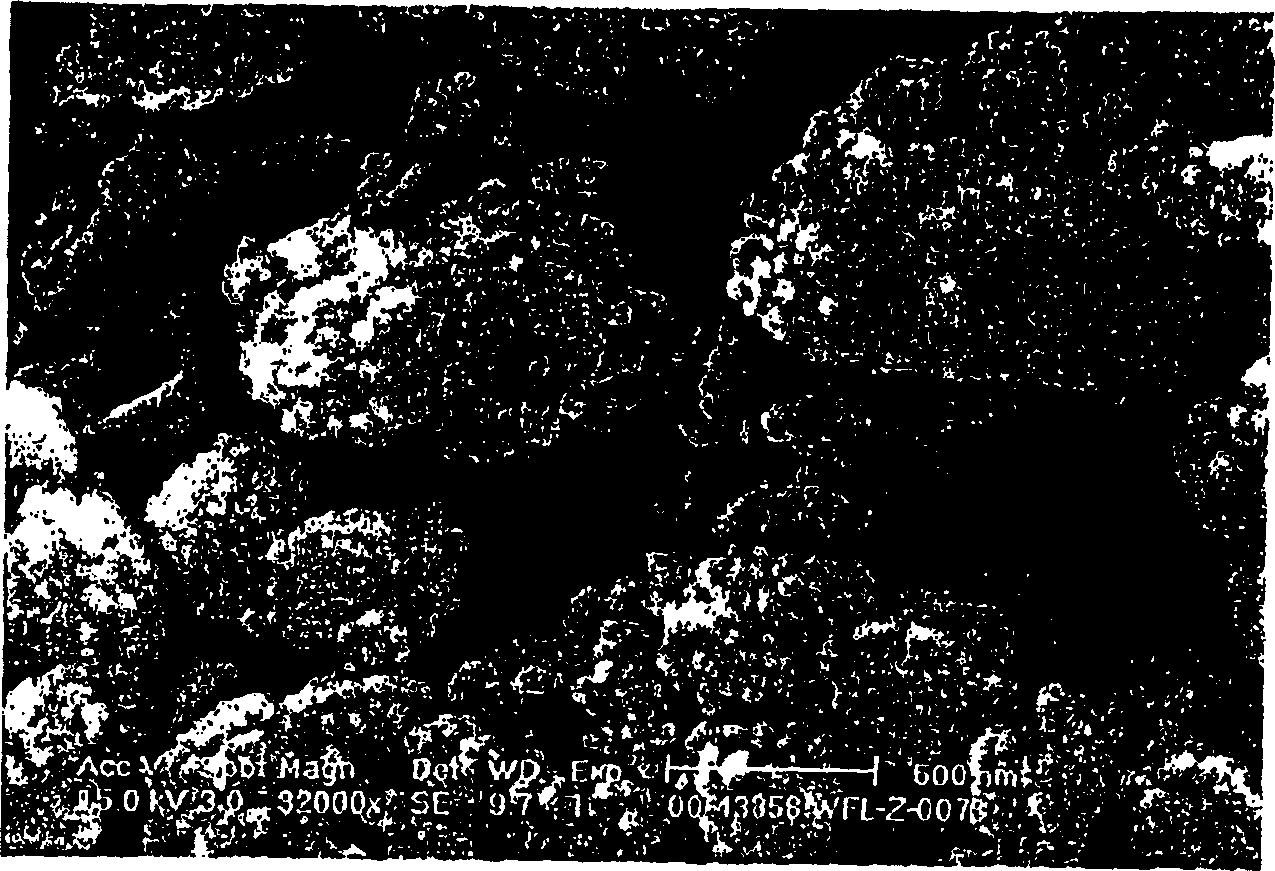

[0083] The mixture was reacted in a 600 ml autoclave at 285°F (140°C) for 168 hours at a stirring speed of 150 RPM. The product was filtered, washed with deionized water (DI) and dried at 250°F (120°C). The XRD pattern of the as-synthesized material shows a typical pure phase of the ZSM-12 topology. The SEM of the synthesized material is shown in image 3 , and show that the material consists of agglomerates of small crystals (average crystal size approximately 0.05 microns).

[0084] The synthesized crystals were converted to the hydrogen form by two ion exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com