Hydrocarbon dehydrogenation catalyst and process

A catalyst and dehydrogenation technology, applied in contact with catalyst composition under dehydrogenation conditions, in the field of hydrocarbon dehydrogenation, to achieve excellent dehydrogenation performance and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Basically follow the exemplary procedure described above to prepare a test promoted catalyst containing 1.91% by weight of sodium. The conversion rates of propane and ethylene of the test promotion catalyst containing 1.91% by weight of sodium are shown in Table 1 below.

Embodiment 2

[0088] Basically follow the exemplary steps described above to prepare a test promoted catalyst containing 1.96% by weight of sodium. The conversion rates of propane and ethylene of the test promoting catalyst containing 1.96% by weight of potassium are shown in Table 1 below.

Embodiment 3

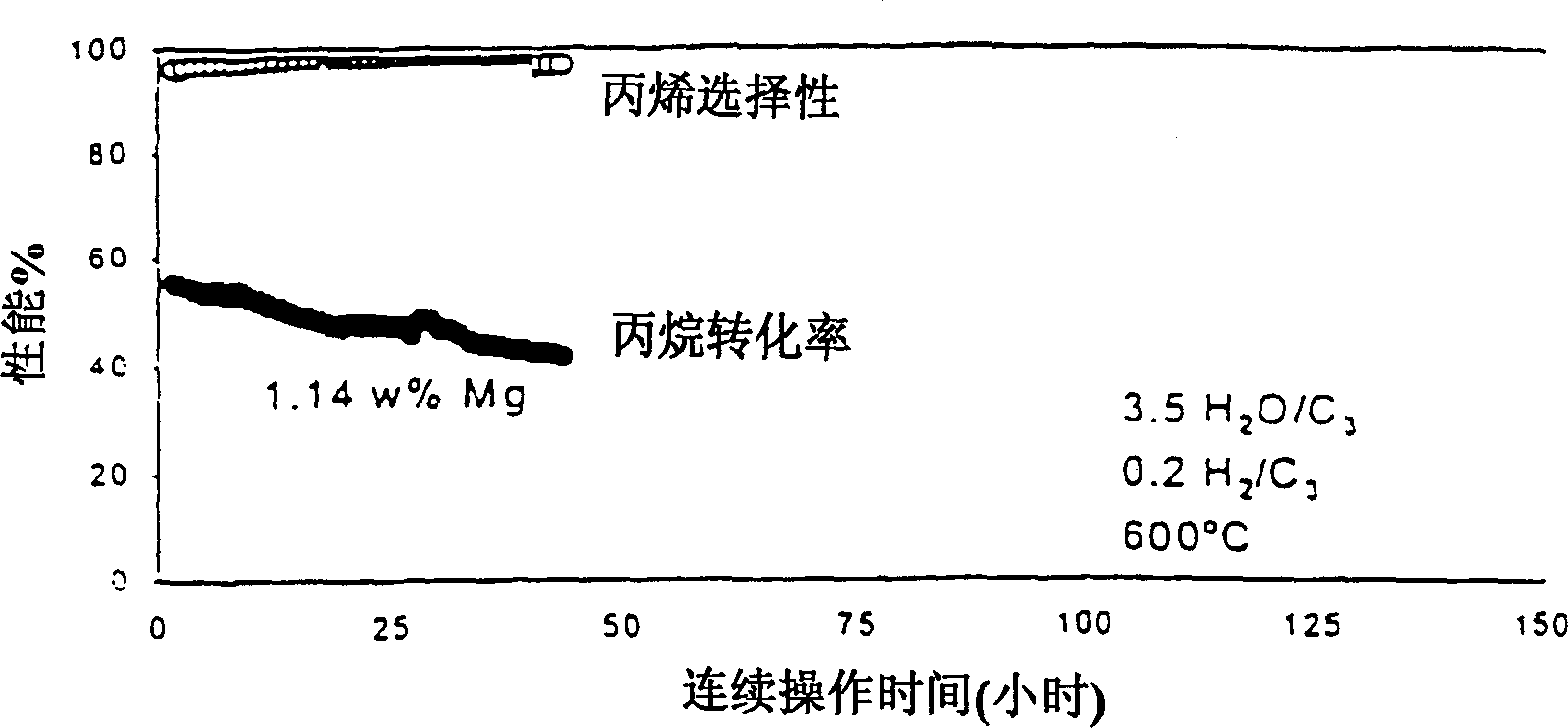

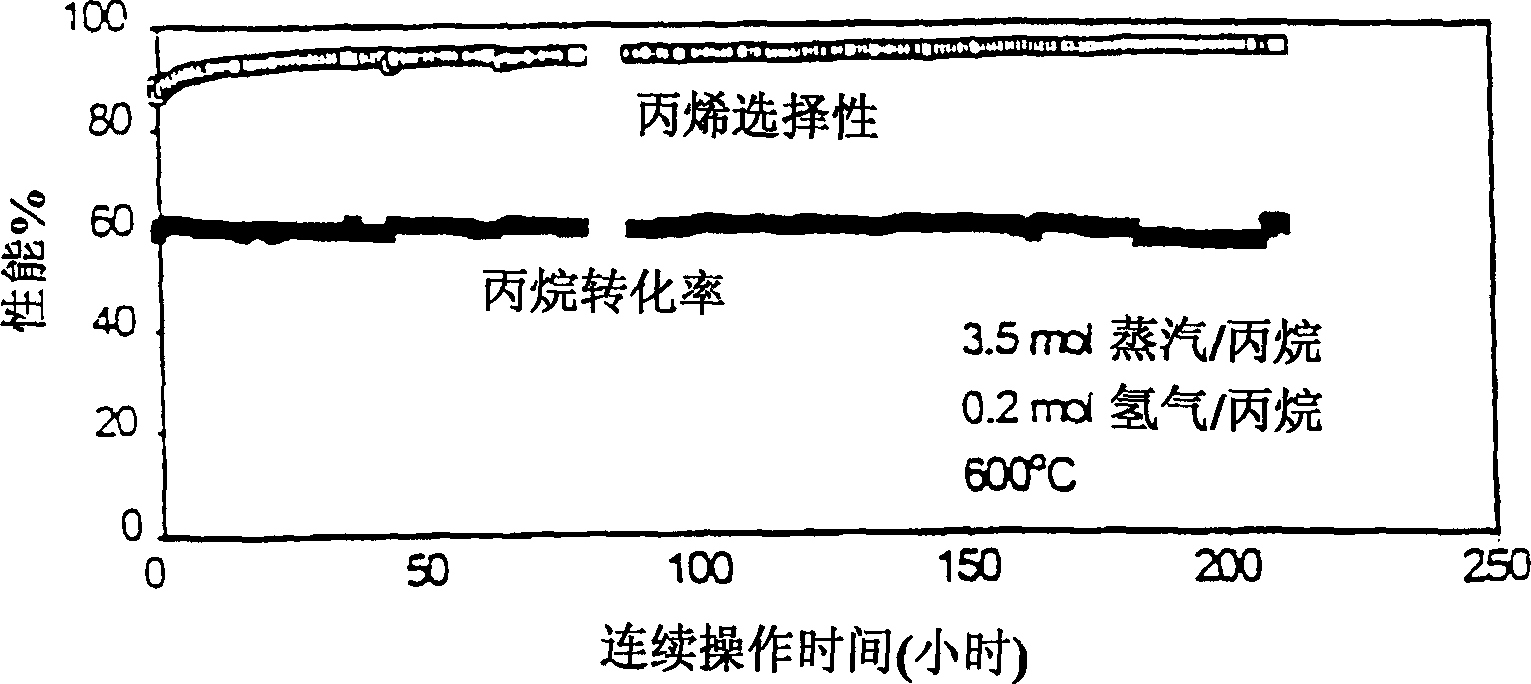

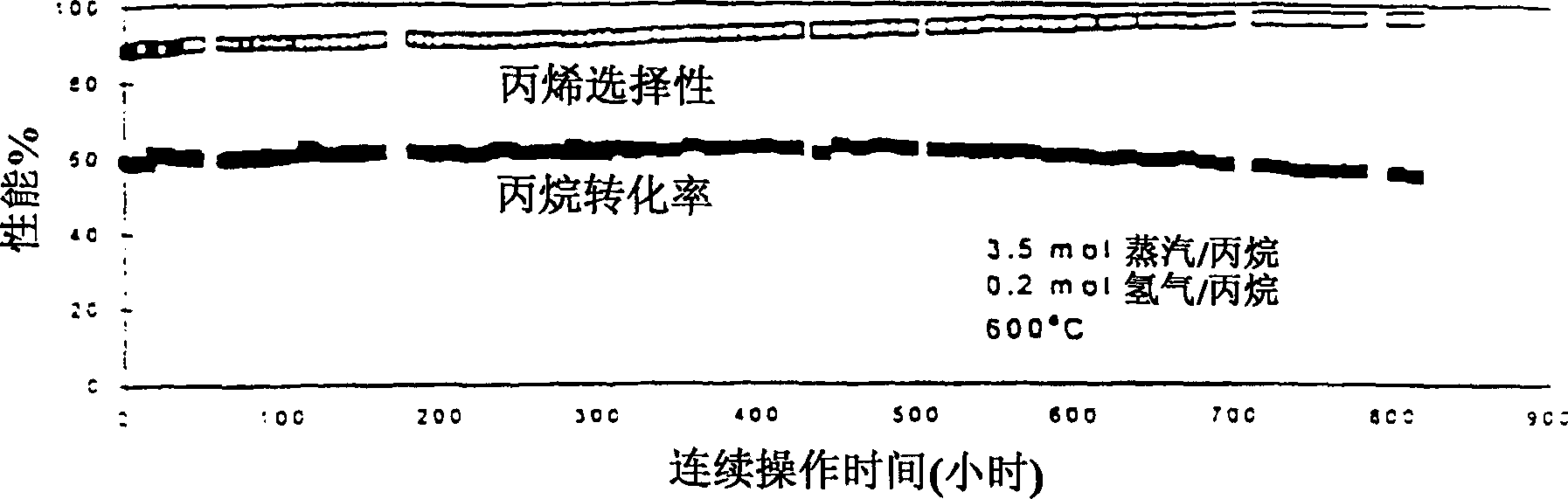

[0090] Basically follow the exemplary procedure described above to prepare a test promoted catalyst containing 1.14% by weight of magnesium. The conversion rates of propane and ethylene of the test promoting catalyst containing 1.14% by weight of magnesium are shown in Table 1 below.

[0091] Promoter

1.91wt% Na

1.96wt% K

1.14wt% Mg

Cycle 1

Propane conversion rate%

a

27

27

27

Cycle 2

Ethylene conversion rate%

b

24

91

83

Cycle 3

Propane conversion rate%

10

24

26

[0092] Note a: The equilibrium conversion of propane under reactor conditions is 27%.

[0093] Note b: Conversion of ethylene to ethane.

[0094] The data in Table 1 shows that under the exemplary test conditions of the promoted catalyst described in Examples 1 to 3, the promoted catalyst containing 1.14% by weight of magnesium is the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com