Automatic image measuring system

An image measurement and automatic technology, applied in the field of computer systems, can solve problems such as failure to achieve automatic operation and insufficient automation performance, and achieve the effects of improving measurement efficiency, high update efficiency, and high portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

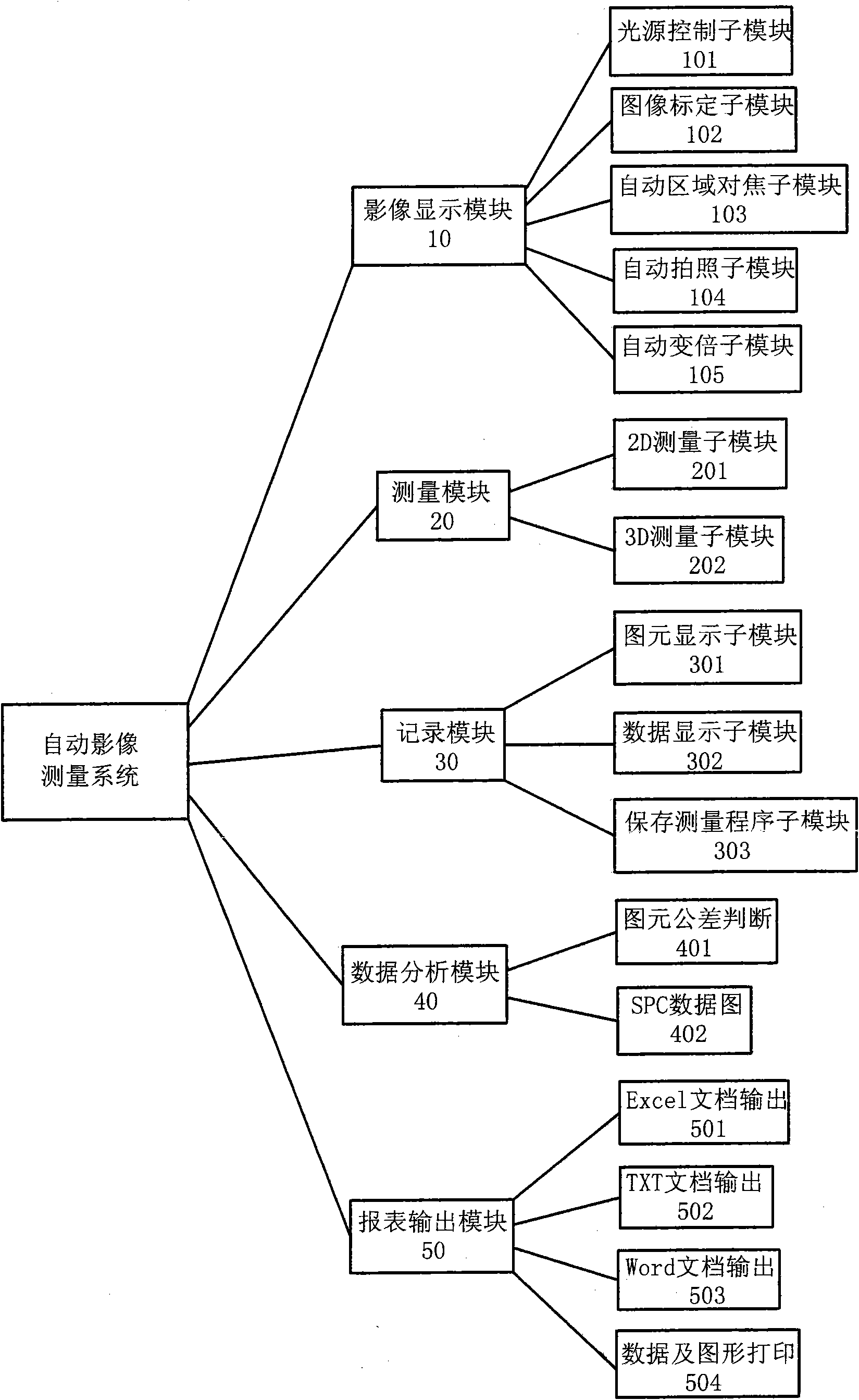

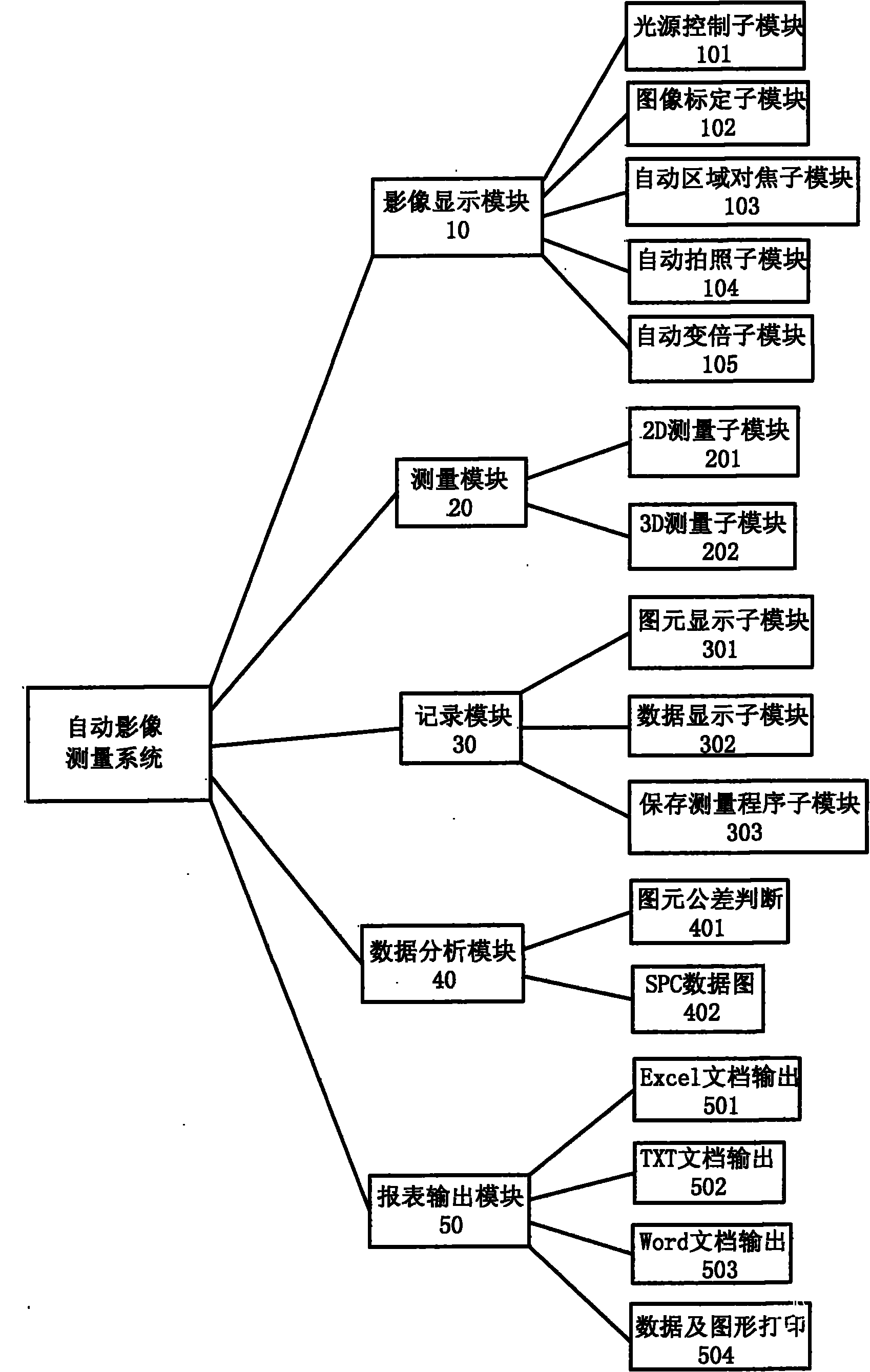

[0027] Such as figure 1 The structure block diagram of the present invention shown, in the figure, an automatic video measurement system for observing, measuring and analyzing workpiece products, including an image display module 10, a measurement module 20, a recording module 30, a data analysis module 40 and report output Module 50.

[0028] The image display module 10 magnifies and captures the image of the workpiece with a high magnification, and can clearly display the structure of each part of the workpiece. It includes a light source control submodule 101 , an image calibration submodule 102 , an automatic area focusing submodule 103 , an automatic photographing submodule 104 and an automatic zoom submodule 105 .

[0029] The light source control sub-module 101 further includes surface light source control, contour light source control and coaxial light source cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com