Thermopile infrared detector and manufacturing method thereof

A technology of an infrared detector and a manufacturing method, which can be applied to electric radiation detectors and other directions, can solve the problems of difficult control of lens curvature, chip distance, focus deviation, etc. The effect of matching and transmission complete suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

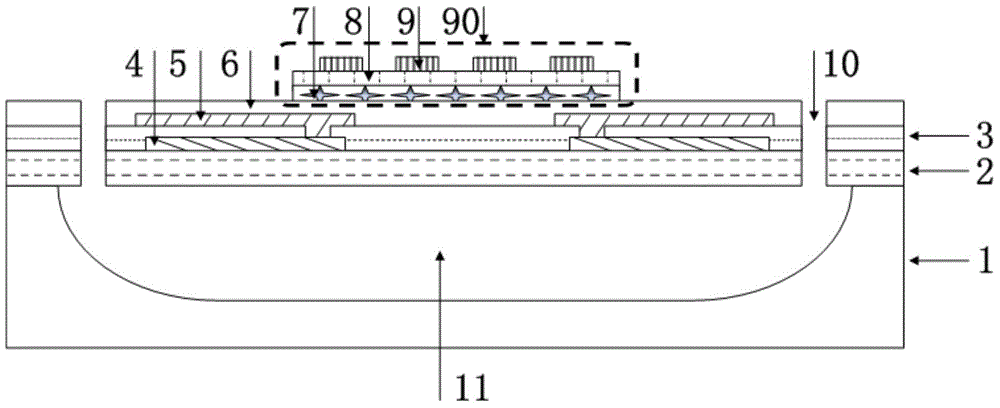

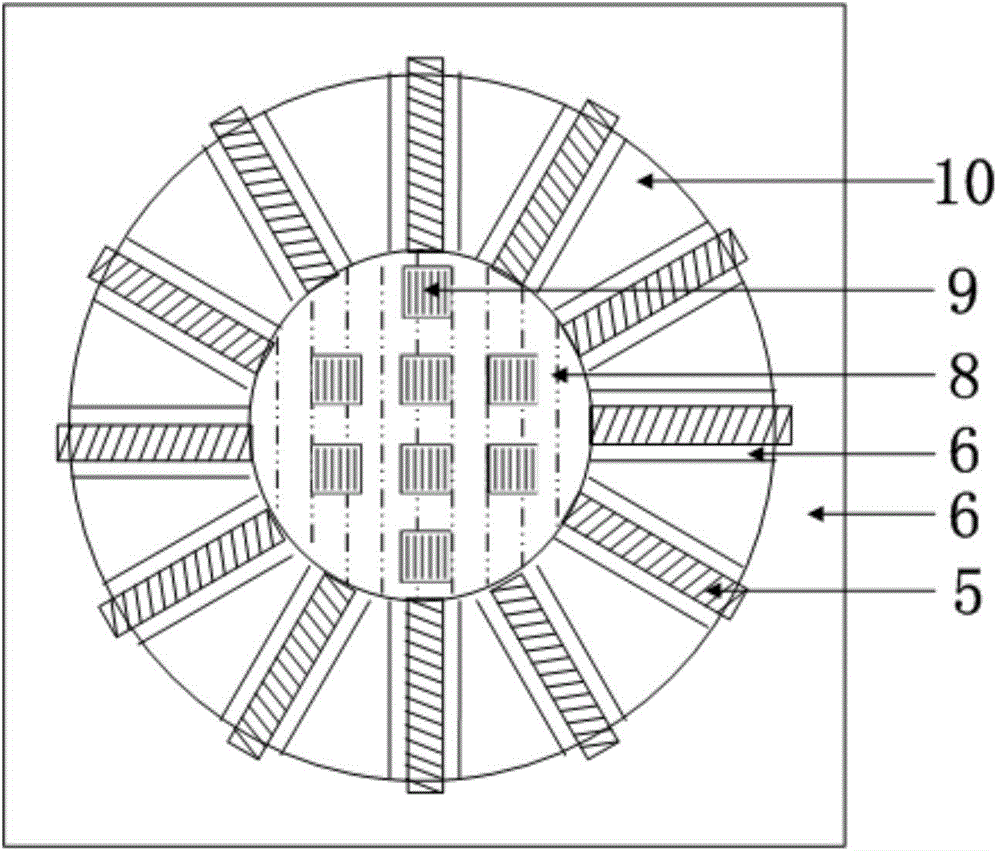

[0077] refer to figure 1 , the thermopile infrared detector can include: a substrate 1 with a cavity 11 in the substrate 1; a dielectric support film 2 positioned above the cavity 11 and supported by the substrate 1; a thermopile positioned as a dielectric above the cavity 11 on the supporting film 2; a passivation layer 6 covering the thermopile; a metamaterial structure 90 located on the passivation layer 6 above the thermopile. Wherein, the substrate 1 and the metamaterial structure 90 serve as the cold junction region and the hot junction region of the thermopile respectively.

[0078] Wherein, the substrate 1 may be various semiconductor substrates in a conventional CMOS process, such as a single crystal silicon wafer or an SOI silicon wafer.

[0079] The material of the dielectric support film 2 may be silicon oxide or silicon nitride, or the dielectric support film 2 may be a composite dielectric film formed of silicon oxide and silicon nitride.

[0080] Thermopiles c...

no. 2 example

[0106] refer to Figure 6 , Figure 6 The cross-sectional structure of the thermopile infrared detector of the second embodiment is shown, and its structure is basically the same as that of the first embodiment, except that the cavity 11 has an open opening on the back of the substrate 1 .

[0107] The manufacturing method of the thermopile infrared detector of the second embodiment is basically the same as that of the first embodiment, the difference lies in the formation method of the cavity 11 and the release method of the thermopile device. After the fabrication of the metamaterial structure is completed, the backside of the substrate 1 is etched and / or wet-etched to form a cavity 11 in the substrate 1 below the thermopile. After the cavity is formed, the dielectric support film 2 above the cavity 11 forms a suspended film structure, and the dielectric support film 2, thermopile and passivation layer 6 form a sandwich structure, thereby releasing the thermopile device. A...

no. 3 example

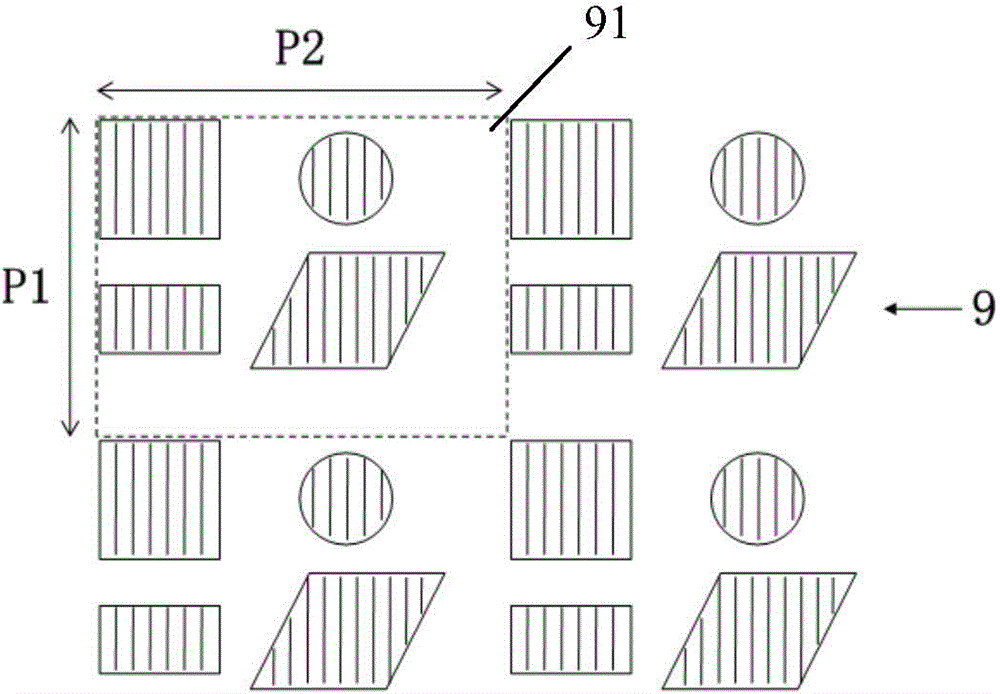

[0110] refer to Figure 7 , Figure 7 The cross-sectional structure of the thermopile infrared detector of the third embodiment is shown. As a preferred embodiment, in the direction perpendicular to the surface of the substrate 1, a plurality of intermediate dielectric layers 8 and a plurality of metal microstructure layers 9 are stacked, and a plurality of intermediate dielectric layers 8 and metal microstructure layers 9 spaced between each other. In other words, a plurality of intermediate dielectric layers 8 and a plurality of metal microstructure layers 9 are sequentially cascaded in a vertical direction in a manner of being spaced apart from each other. For example, Figure 7 It contains three intermediate dielectric layers 8 and three metal microstructure layers 9 .

[0111] Wherein, each intermediate dielectric layer 8 may be made of different dielectric materials, or may be the same dielectric material with different thicknesses. Metal microstructure layers 9 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com