Automatic detecting and imaging method of hyper-acoustic phased array of weld joint in complex space

An ultrasonic phased array, automatic detection technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, to achieve the effect of simplified steps, low cost and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

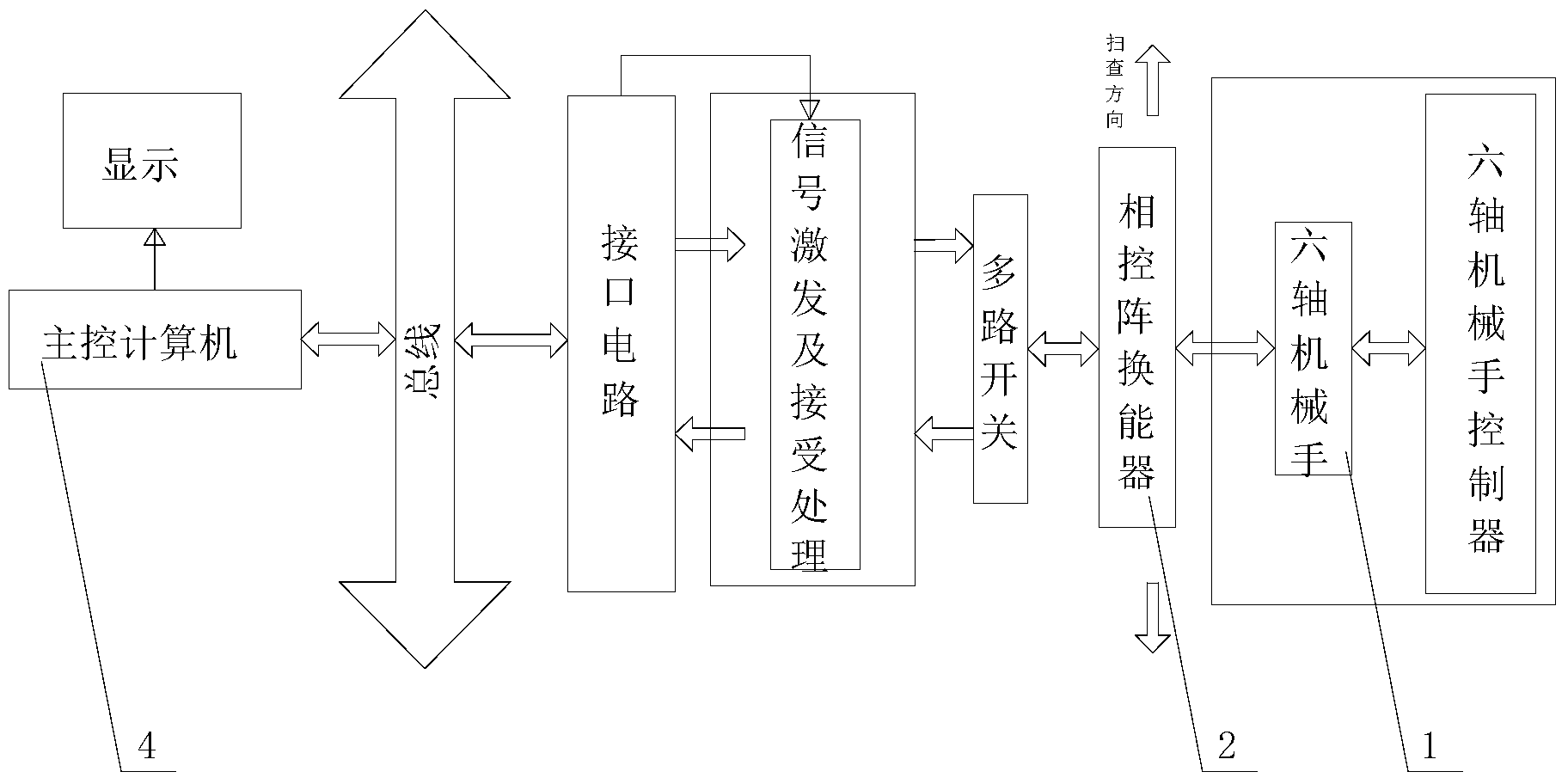

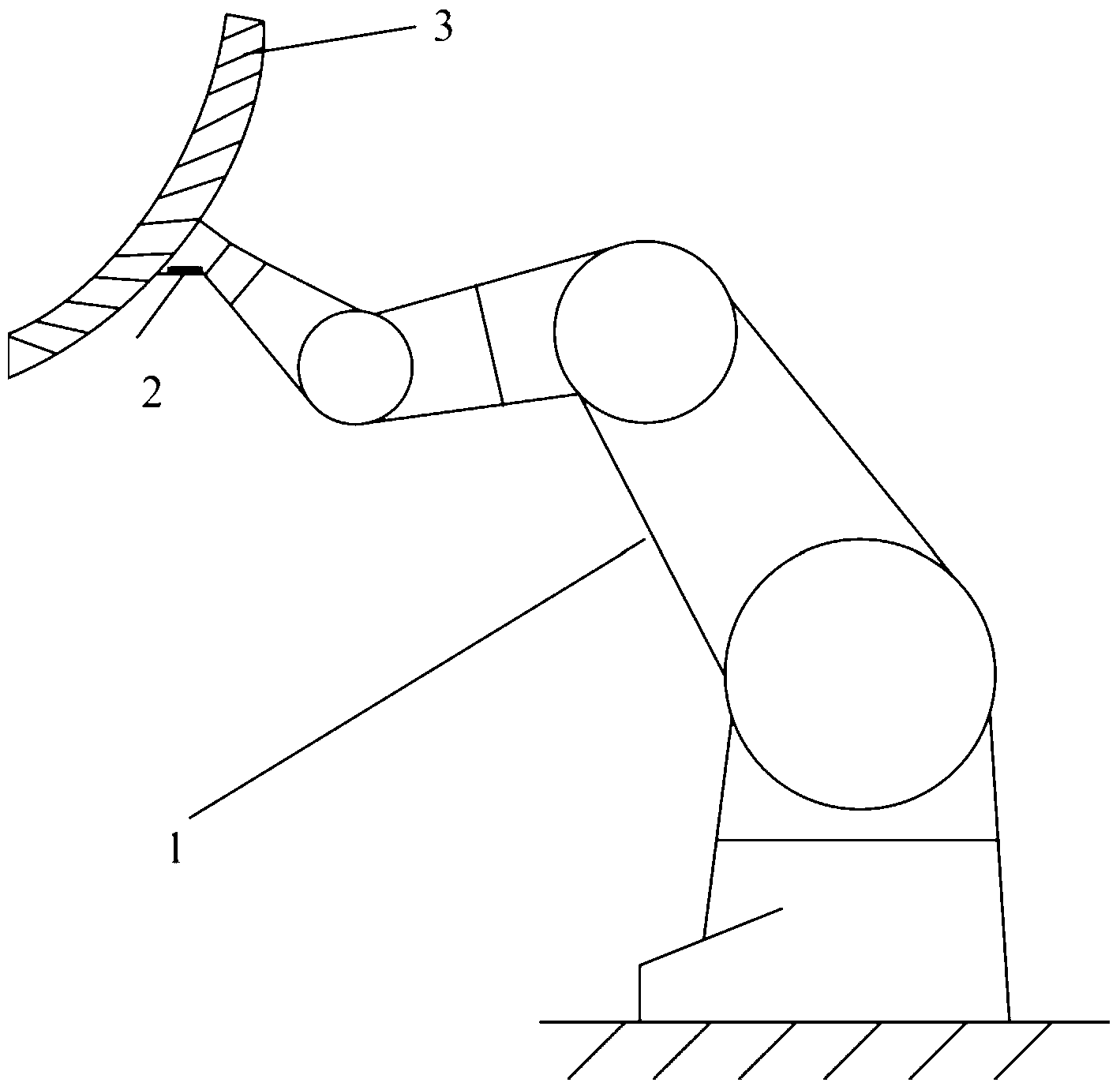

[0031] An ultrasonic phased array automatic detection and imaging method for complex space welds according to the present invention, the steps are:

[0032] 11) Determine the scanning trajectory according to the three-dimensional CAD model of the complex space;

[0033] 12) Utilize the six-axis manipulator 1 to clamp the ultrasonic phased array transducer 2 to track and scan the weld 5 along the determined scanning trajectory, obtain the test data of the weld 5, obtain the test result of the weld, and display the test result of the weld In 3D weld graphics. Introduce manipulator into weld inspection to realize efficient automatic inspection. The application of computer 3D visualization technology allows the inspection results to be more intuitively displayed in the 3D geometry of the workpiece, which is convenient for inspectors to locate and quantify defects, and inspectors can intuitively observe the defects of welds.

[0034] If the 3D CAD model of the complex space is kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com