Splicing exposing method for photo-etched large-size CCD (Charge Coupled Device) chip

An exposure method and a large-scale technology, which are applied in microlithography exposure equipment, photolithography exposure devices, optics, etc., can solve problems such as narrowing, widening of lines, and deformation of geometric connections, so as to improve performance or quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

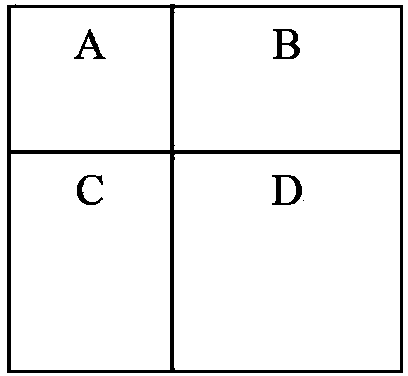

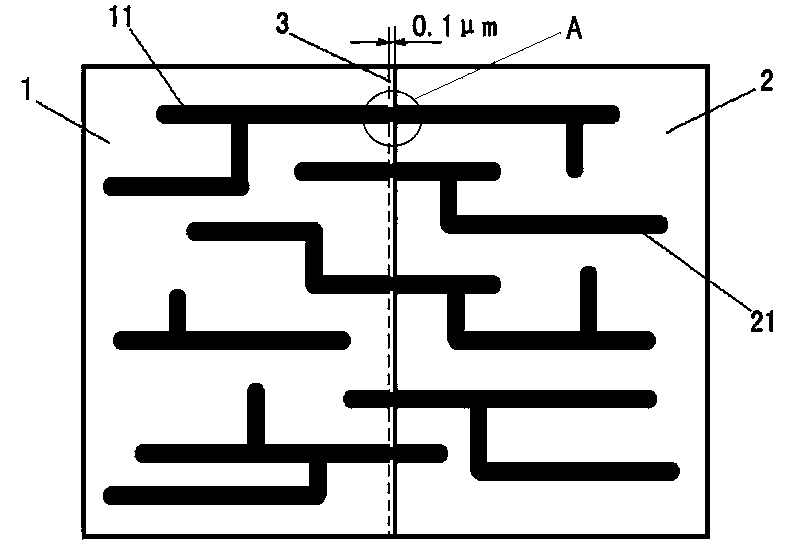

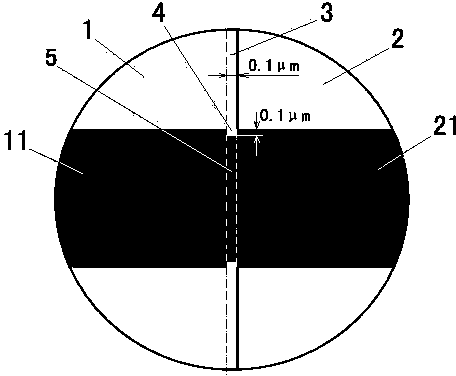

[0022] attached figure 1 It is a schematic diagram of making a large-size CCD chip by means of splicing photolithography exposure. In the figure, A, B, C and D are four CCD splicing chips of a large-size CCD chip. It can be seen from the figure that in practical applications, the size of a single CCD chip is larger than the maximum exposure field of view of a lithography machine. For example, the chip size of a long line array CCD is 2mm×80mm, and the size of a large area array CCD chip even reaches 96 mm×96mm . Although the wafer required to make a large-size CCD chip can meet its size requirements, due to the limitation of the maximum exposure field of view of the lithography machine, it is still impossible to transfer the geometry on the mask plate to the wafer through one exposure. It is processed by splicing exposure. The so-called splicing exposure refers to dividing a large-size CCD chip into several CCD splicing chips whose size is smaller than or equal to the maximu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com