Method for machining crooked neck nicking color ring easy-to-break ampoule

A processing method and color ring technology, applied in the field of pharmaceutical packaging materials, can solve the problems of nurses being injured during operation, affecting the safety of ampoules, and difficult to break ampoules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

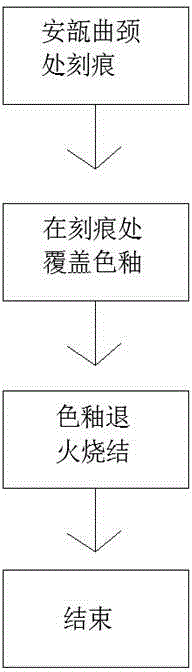

[0018] figure 1 Shown: a kind of processing method of curved neck scoring color ring easy to break ampoule, concrete steps are:

[0019] 1. A high-speed rotating knife is used to score one week at the curved neck of the ampoule, where the width of the score is 0.2mm and the depth is 0.05mm. When the bottle passes through the high-speed scoring motor, the neck is in natural contact with the high-speed rotating scoring knife and rotates 100% of the time. Even if the outer diameter of the neck deviates by 2mm, the scoring knife can naturally fit the scoring through the leverage of the counterweight. The width is 0.2mm, the depth is 0.05mm, and the length is one week. The cuts are uniform, stable and consistent, and no additional control mechanism is required;

[0020] 2. Cover the notch with a layer of colored glaze with a width great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com