PVC pipe cutting process

A cutting process, PVC pipe technology, applied in metal processing and other directions, can solve the problems of low cutting efficiency, low precision, burrs, etc., and achieve the effect of improving cutting quality, high production efficiency, and smooth section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

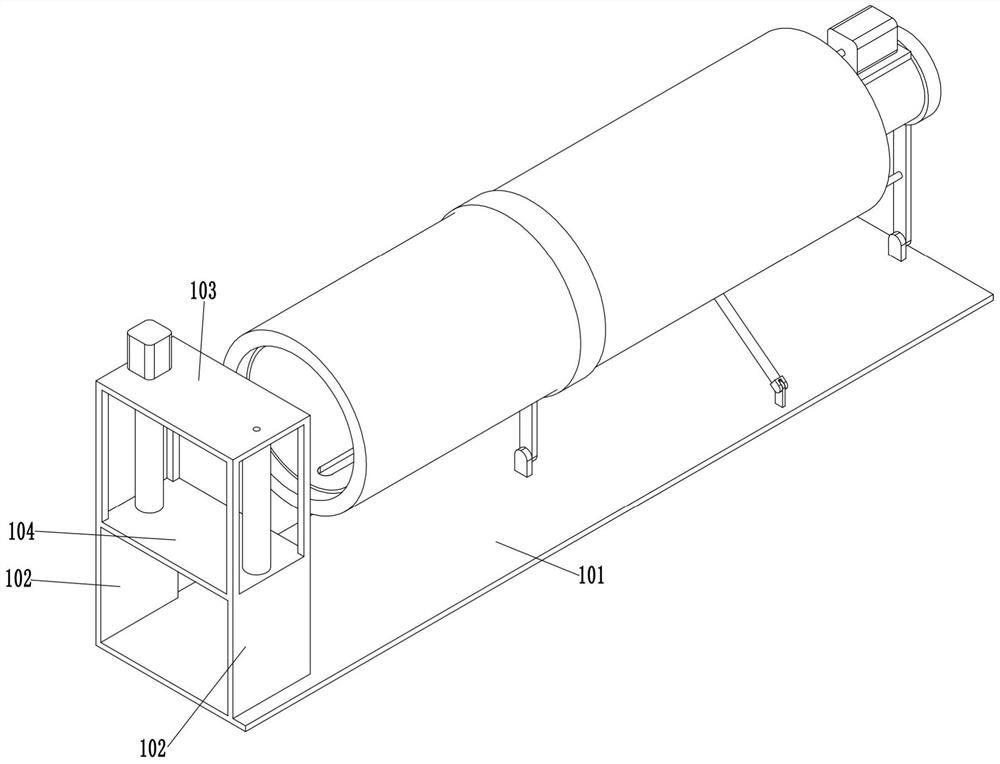

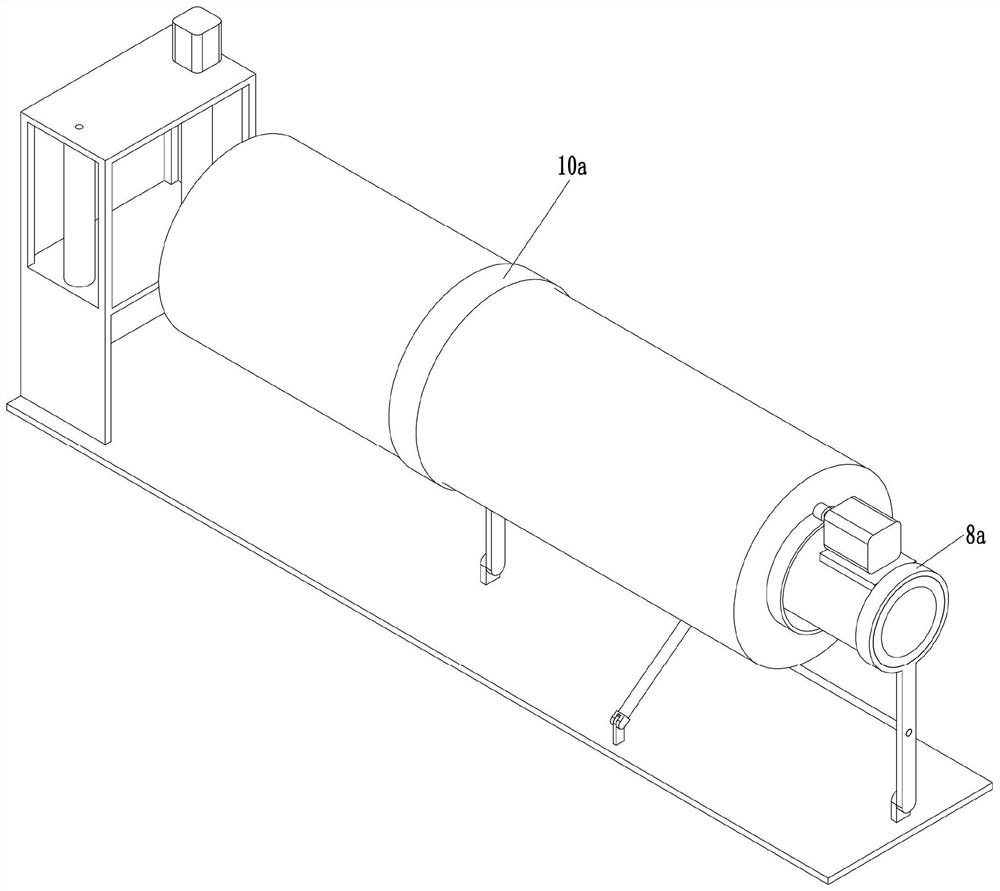

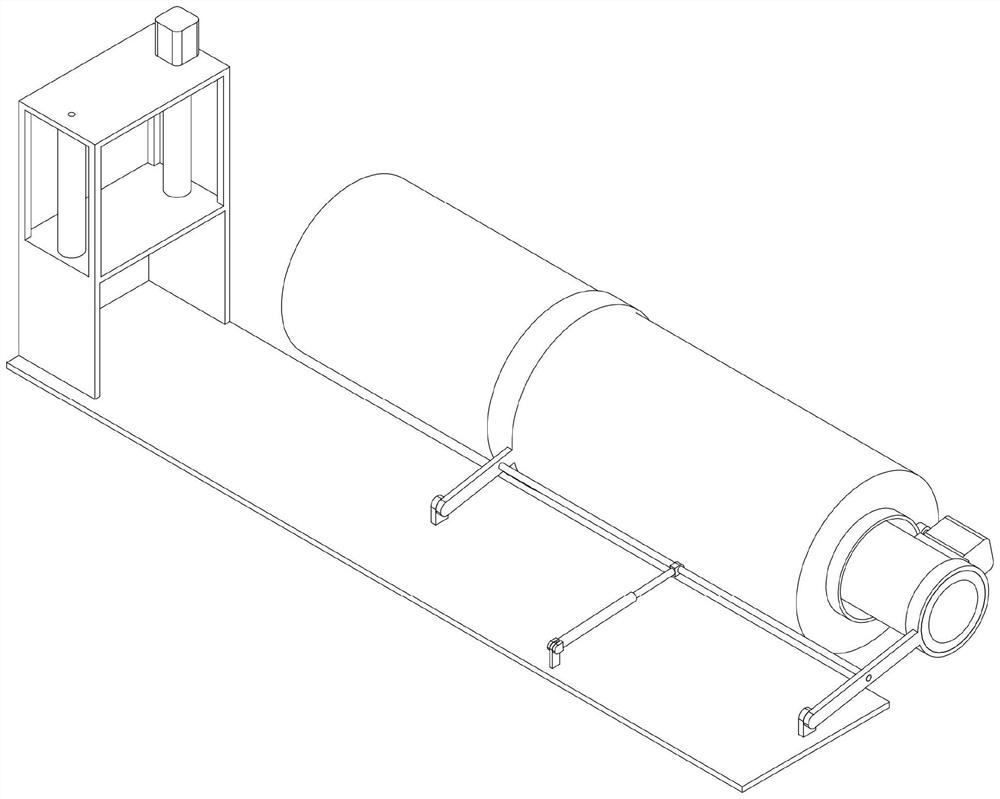

[0047] see Figure 1-16 Shown, a kind of PVC pipe cutting process comprises the following steps:

[0048] Step 1, controlling the transposition component to send the cutting tube 2 to the feeding position facing the feeding component;

[0049] Step 2, put one end of the whole pipe into the feeding assembly, and the feeding assembly feeds the pipe into the cutting pipe 2;

[0050] Step 3, the control fixture assembly fixes the pipe fittings protruding into the cutting pipe 2, and drags the pipe fittings into the cutting pipe 2 according to the required cutting length;

[0051] Step 4, controlling the distance between multiple nozzles in the high-pressure nozzle assembly;

[0052] Step five, supply high-pressure water to multiple nozzles through high-pressure hoses, and control the rotation of the pipe fittings to complete the multi-section cutting of the pipe fittings;

[0053] Step 6, control the reverse rotation of the feeding assembly to withdraw the remaining pipe fittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com