Automatic disconnection device of a fin

A technology for automatic cutting and finning, which is applied to shearing devices, devices for cutting with nibbling action, attachments to shearing machines, etc., which can solve the problems of low production efficiency, curling of fin sections, affecting assembly, etc. Achieve the effect of high work efficiency, smooth section and concentrated force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

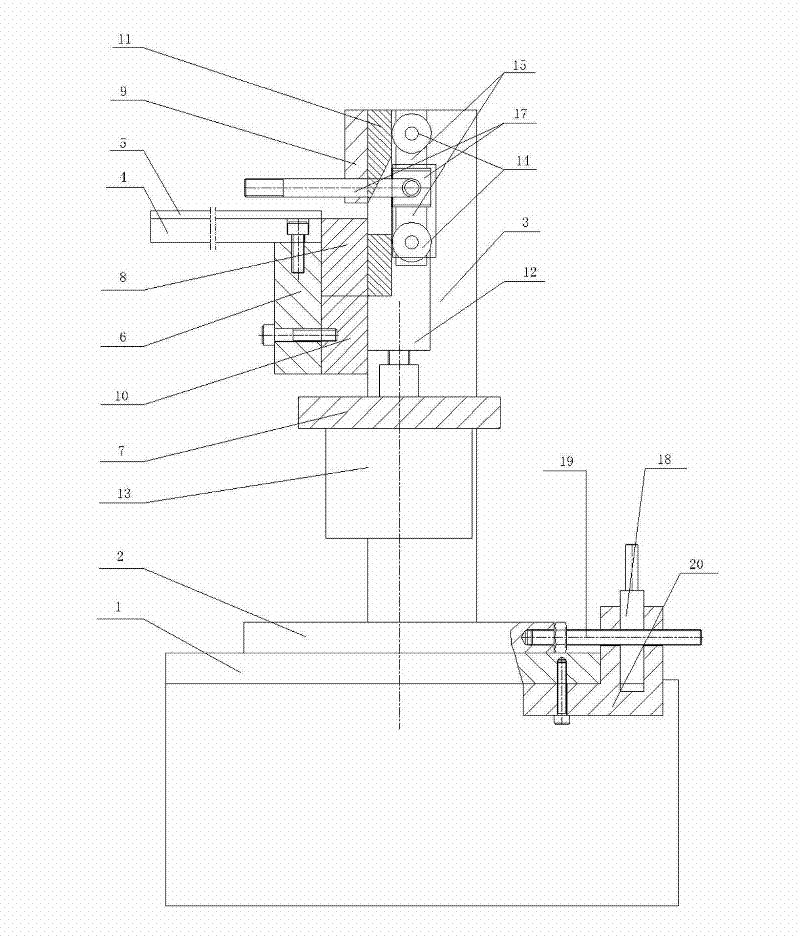

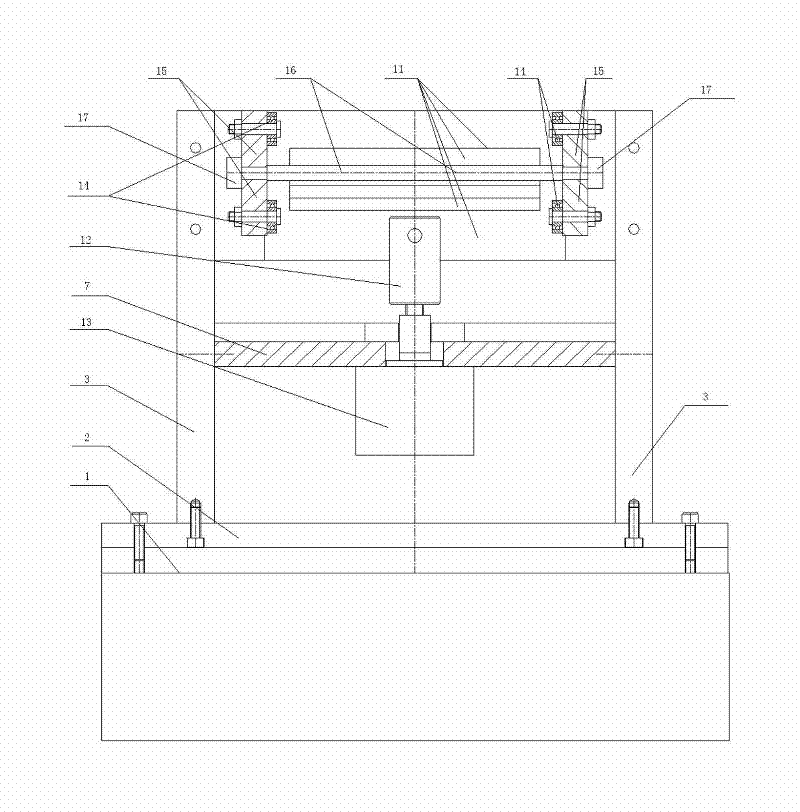

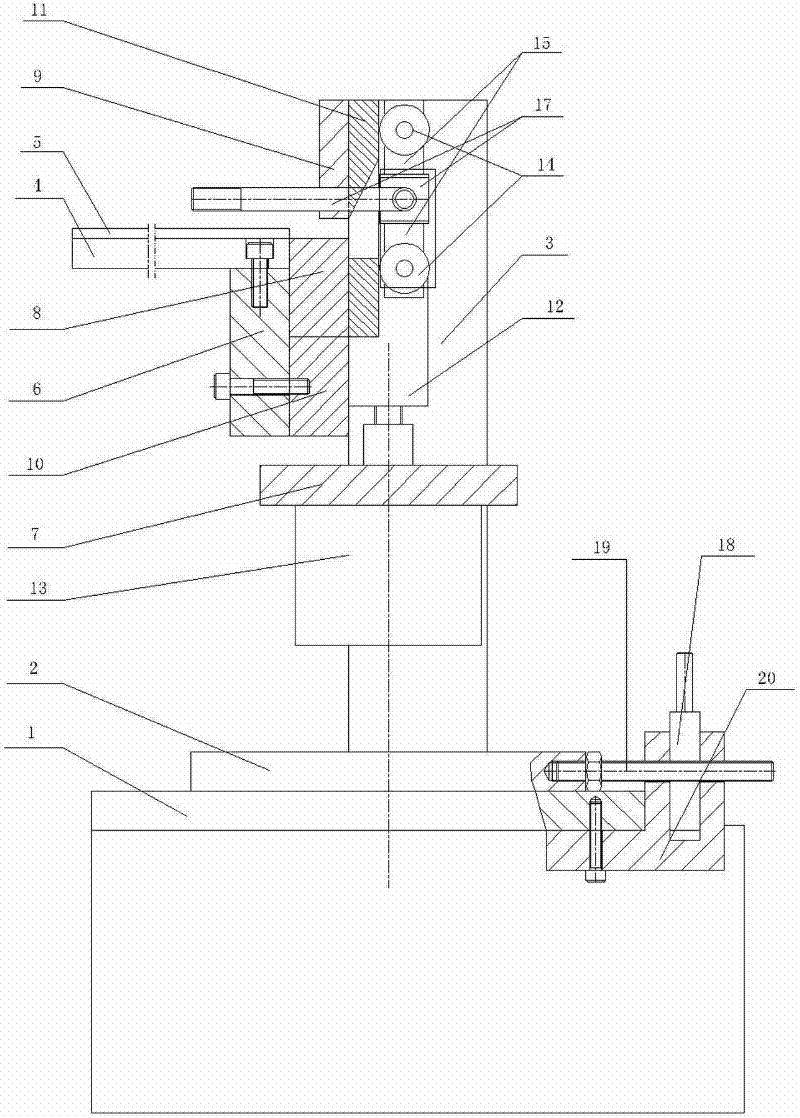

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] see figure 1 and figure 2 As shown, the fin automatic cutting device of the present invention includes a frame and a cutting pier 8 fixed on the frame, and it also includes a cutter assembly slidingly fitted on the frame, and the cutter assembly is connected with the drive mechanism, The vertical surface of the cutting pier 8 is matched with the blade clearance of the cutter 11 in the cutter assembly.

[0020] Described frame comprises the first base plate 1 that is provided with support, the second base plate 2 that is fixed on the first base plate 1, two vertical plates 3 that are fixed on the second base plate 2, described two vertical plates 3 A connection plate 7 is provided between them.

[0021] The drive mechanism includes a cylinder 13 fixed on the connecting plate 7 and controlled by a counting relay, and the free end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com