Cutting and falling device for chip packing pipe

A blanking device and packaging tube technology, which is applied in metal processing and other directions, can solve the problems of chip packaging tube mouth deformation and chipping, chip packaging tubes are prone to chipping, and production efficiency is low, so as to avoid chipping and deformation , smooth cross-section, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

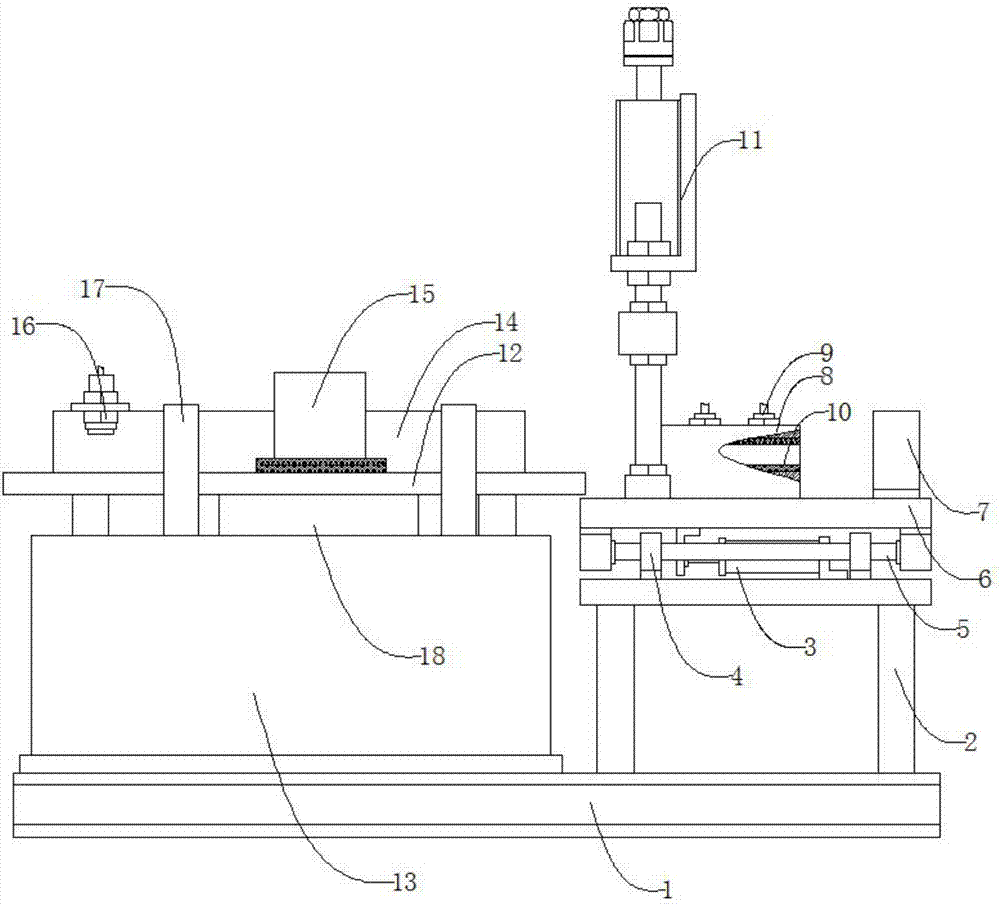

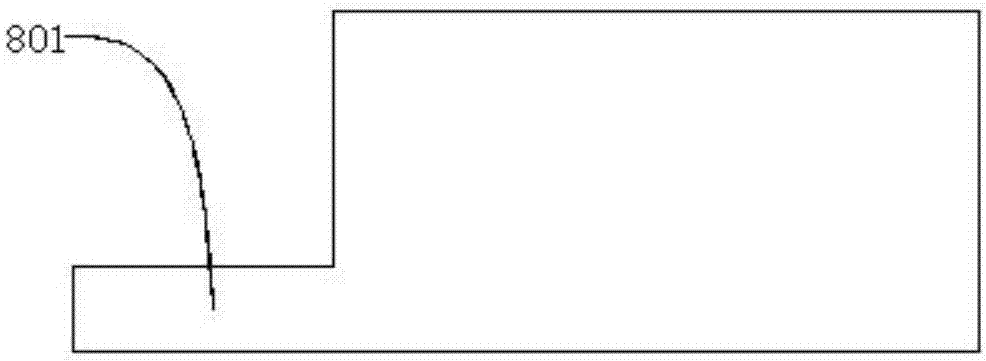

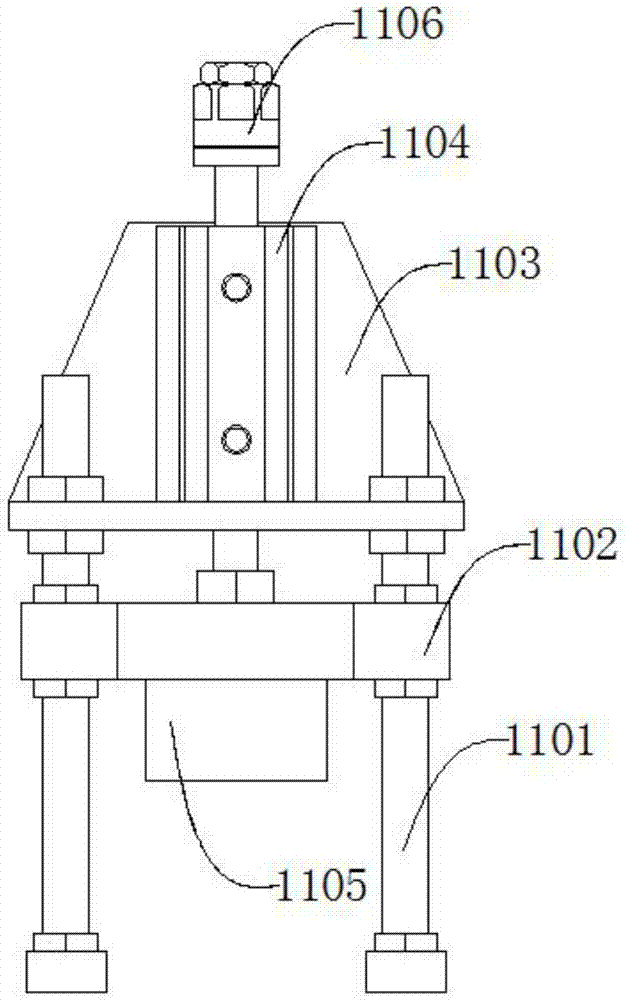

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6As shown, a chip packaging tube cutting and blanking device includes a base 1, a right table 2, a feeding cylinder 3, a guide seat 4 symmetrically arranged along the right table 2, a guide rod 5, and a supporting plate 6 , limit seat 7, aluminum mold 8, heating tube 9, copper sleeve 10, cutting mechanism 11, left workbench 12, material box 13, adjustment seat 14, pushing mechanism 15, photoelectric sensor 16, retaining strip 17, guide Material plate 18, the right side table 2 is located on the right side of the upper end of the base 1, the right side table 2 is threadedly connected with the base 1, the delivery cylinder 3 is located at the upper end of the right table 2, the The feeding cylinder 3 is threadedly connected with the right table 2, the guide seat 4 is located at the upper end of the right table 2, the guide seat 4 is threaded with the right table 2, and the guide rod 5 runs thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com