Ampoule bottle opener

A technology of ampoule bottle and bottle opener, which is applied in the direction of bottle/container cap, opening closed container, bottle filling, etc. It can solve the problems of liquid medicine reagent waste, injury to medical staff, broken ampoule bottle, etc., and achieve a smooth cross-section , Reliable performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

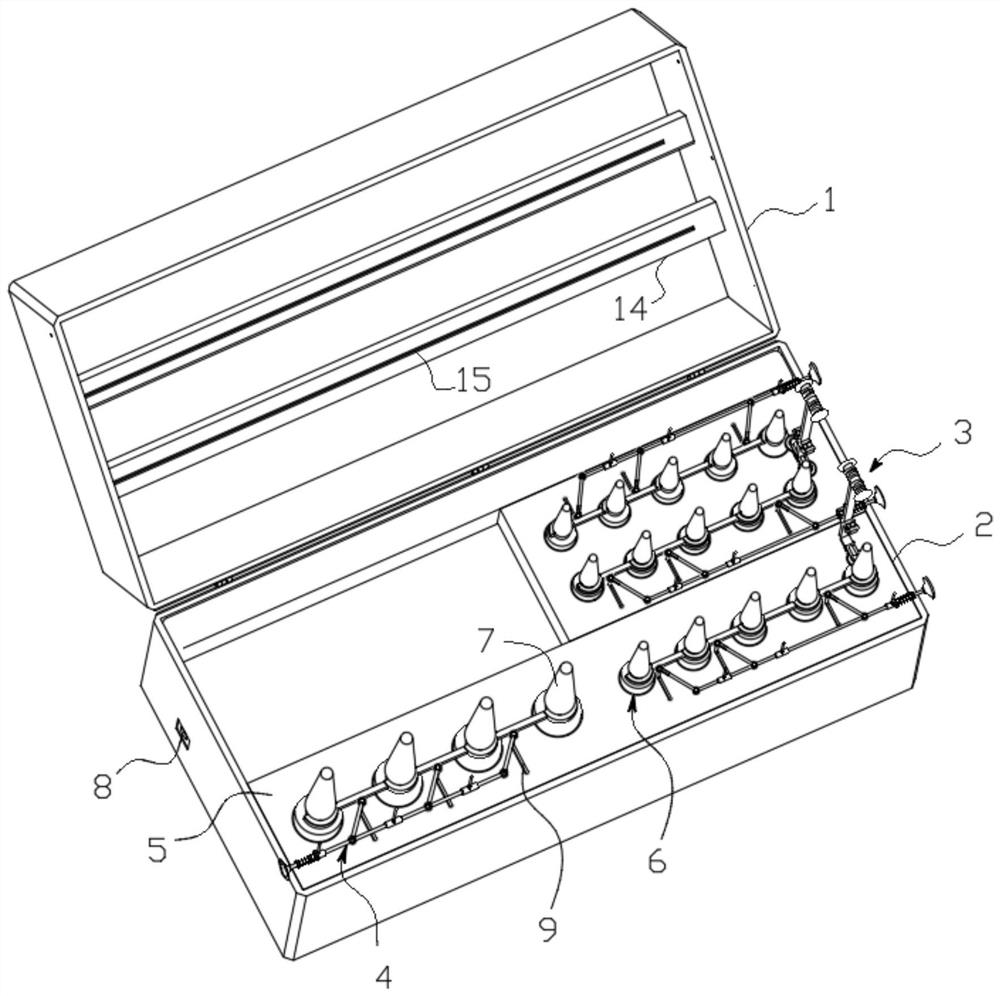

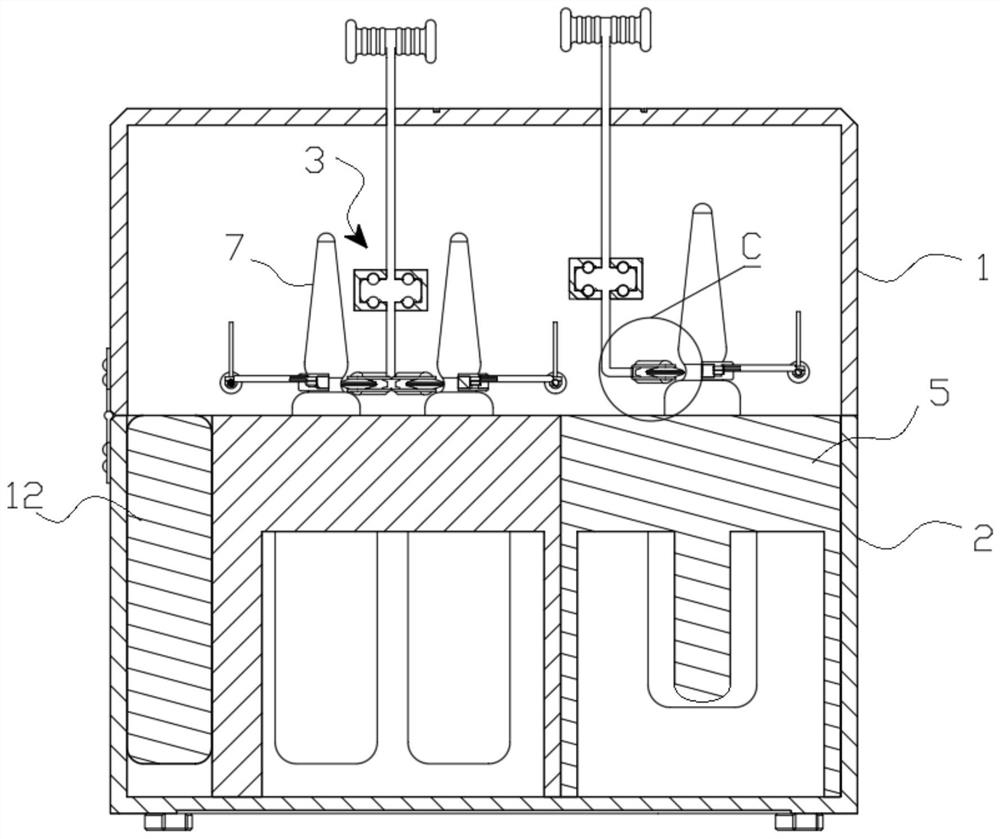

[0046] Combined with the manual Figure 1-4 , A kind of ampoule bottle opener shown in 6-8, comprises the upper box body 1 and the lower box body 3 that can be opened and closed by hinge, the described lower box body 2 is provided with support platform 5, and described support platform 5 There are accommodating holes 6 of various sizes and specifications for placing ampoules 7 on the top, and a freely rotatable tray is provided at the bottom of any accommodating hole 6, as well as a control circuit board 10, a lithium battery 12 electrically connected to the control circuit board 10 and A power port 8 for charging; the upper box body 1 is provided with at least one set of cutting mechanism 3 that slides back and forth to form a physical scratch on the neck of the ampoule 7, and the neck of the ampoule 7 can be stretched and heated The heating mechanism 4; the heating mechanism 4 is powered and heated by the control circuit board 10. When it is necessary to open the ampoule bo...

Embodiment 2

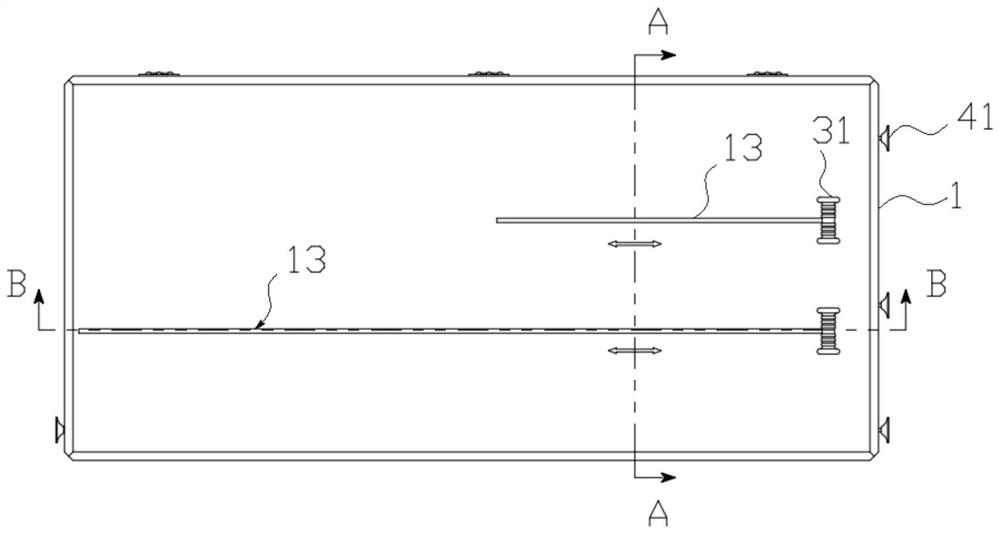

[0048] This embodiment is based on Embodiment 1 in order to facilitate the one-time processing of multiple ampoules 7 of the same specification and improve the convenience of opening the bottle. Figure 1-10 , 12-13, the receiving holes 6 of the same size are arranged in a row on the support platform 5, and the upper box body 1 is provided with a slide rail 14 supporting the cutting mechanism 3, and the slide rail The length direction of 14 is parallel to the central connection line of the receiving holes 6 arranged in a row; the cutting mechanism 3 cuts the surface of the bottle neck of the ampoule bottle 7 by reciprocating sliding on the slide rail 14 . The cutting device 3 is sequentially provided with a handle 31, a push rod 32, a sliding head 33, and a knife holder 36 connected to each other from top to bottom, and is connected to the knife holder 36 in rotation and can move back and forth radially along the knife holder 36 for cutting ampoules. The hob 37 of the bottle 7...

Embodiment 3

[0051] In order to improve the compatibility of the cutting device 3, this embodiment accommodates the installation or placement errors between the cutting device 3 and the ampoule bottle 7. In this embodiment, the knife holder 36 includes a knife holder housing 361, and the inside of the knife holder housing 361 is A cavity for accommodating the first return spring 363 is arranged symmetrically along the radial direction. The hob 37 is axially provided with a rotating shaft 362 , and the end of the rotating shaft 362 is in contact with the first returning spring 363 in a compressed state. lean and can slide back and forth along the length direction of the first return spring 363 . Since there may be an error gap in the assembly of the ampoule bottle 7 and the hob 37, in order to better realize the contact between the hob knife and the ampoule bottle 7, the contact distance between the hob knife 37 and the ampoule bottle 7 is elastically adjusted. The hob 37 can be adjusted ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com