Method for cutting flat stone through long crack propagation

A technology of crack extension and flat plate, applied in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of rough section, high cost, poor quality, etc., and achieve the effect of smooth section and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

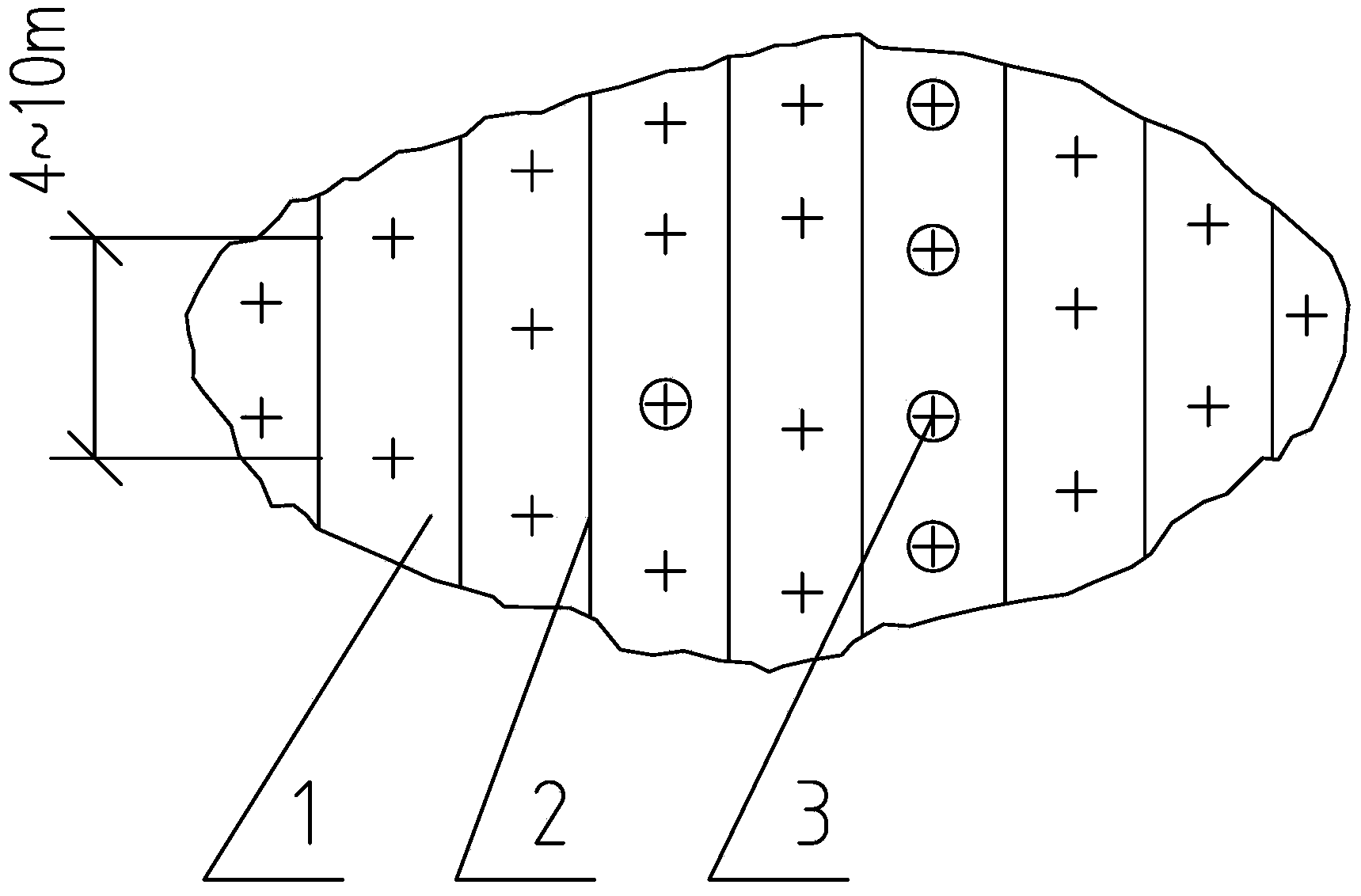

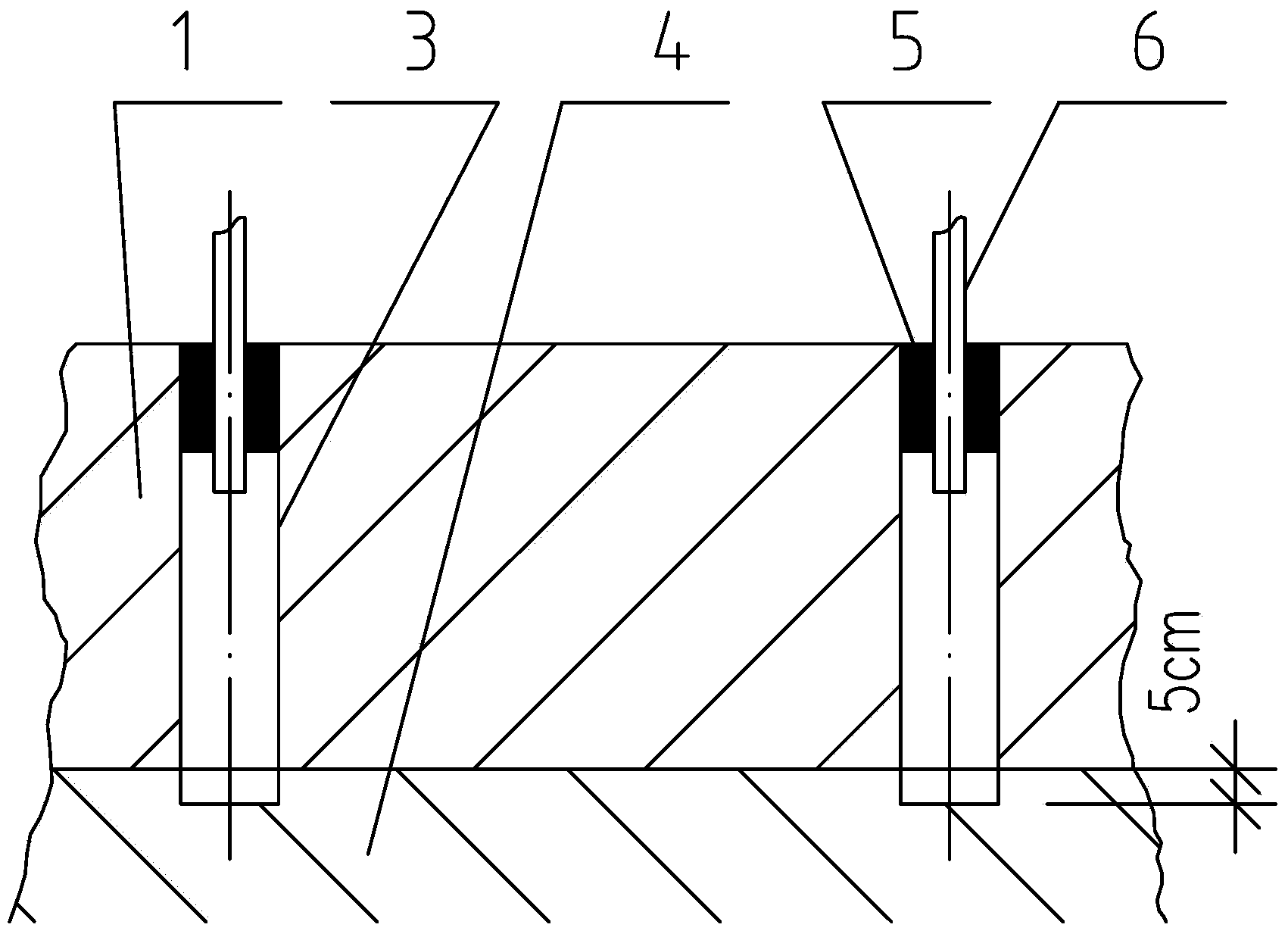

[0039] Such as figure 1 , 2 As shown, draw a predetermined vertical section position on the surface of the flat stone 1 to form section lines, the distance between the section lines is the width of the feldspar strip, and the width is not less than the thickness of the flat stone. Cut a through-long crack groove 2 with a depth of 0.15-0.3m at the predetermined vertical section position with a road repairing slitting machine. The greater the thickness of the flat stone, the greater the depth of the crack groove 2 within the range of 0.15-0.3m. Between the two crack grooves 2, a series of alternating holes 3 are drilled with a rock drill, and the diameter of the alternating holes 3 Preferably 40-60mm, the pitch of the alternating holes is 4-10m, and the hole depth is 4-10cm larger than the thickness of the flat stone, preferably 5cm, that is, entering the rock mass 4. The flat stone 1 is only placed on the upper end of the rock mass 4 (the flat stone has been separated from th...

Embodiment 2

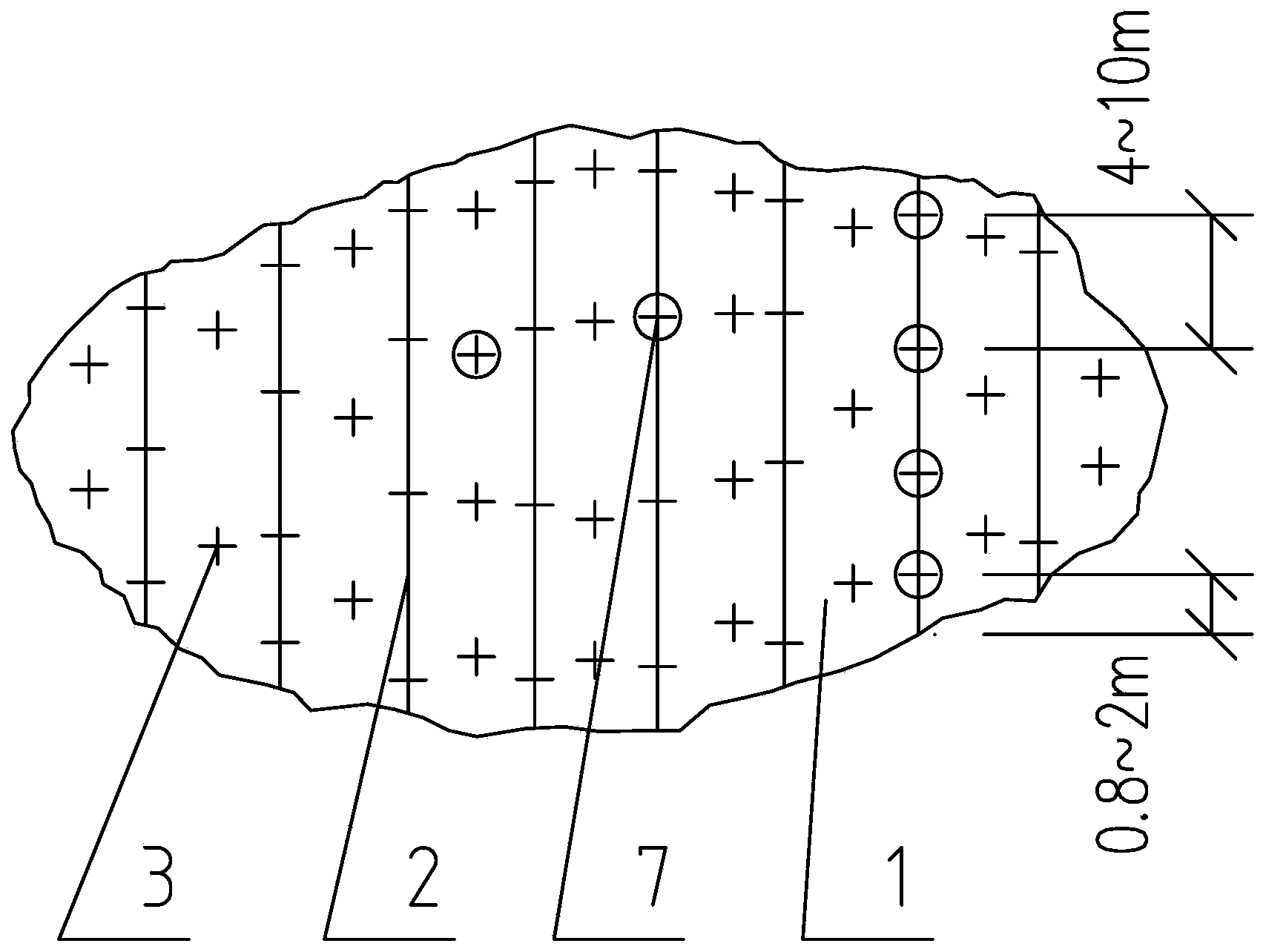

[0042] In order to better limit the crack propagation direction on the vertical plane, a guide hole 7 is provided in the crack groove 2 of the first embodiment. Utilize the crack groove 2 and the groove line of the guide hole 7 hole wall to have a guiding effect, and the crack propagation direction is limited to the vertical plane where the crack groove and the groove line of the guide hole 7 hole wall are located.

[0043] Such as image 3 , 4 As shown, draw the vertical section position on the surface of the flat stone to form a section line. The distance between the section lines is the width of the feldspar strip, and the width is not less than the thickness of the flat stone. Add a plurality of guide holes 7 on the section line, the distance between the guide holes 7 is 4-10m, and the two guide holes 7 close to the two edges of the flat stone are 0.8-2m away from the edge of the flat stone. The diameter of the guide hole 7 is 40-60mm, which is the same as the diameter o...

Embodiment 3

[0048] Such as Figure 5 As shown, in order to reduce the mining equipment used, this embodiment reduces the water pump and pipeline 9 in Embodiment 2, and uses the expansion agent to be filled in the guide hole 7 and the crack groove 2 (expansion cement is selected as the expansion agent). The pressure produced by the expansion agent after expansion also increases with time, until it stabilizes after reaching the maximum expansion force. The maximum expansion force produced), so that the cracks in the crack groove 2 and the vertical groove 8 in the guide hole are in a quasi-static stress state of expanding. Then start the hydraulic system with alternating output pressure, and use the alternating water pressure pressed into the gap between the flat stone 1 and the rock mass 4 to generate alternating force in the vertical direction on the flat stone, and through the effect of alternating tensile stress, cracks The crack tip of the groove 2 generates alternating tensile stress ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com