Paper cutting device

A cutting machine and paper cutting technology, applied in metal processing and other directions, can solve the problems of easy tearing and damage of the gap, time-consuming and labor-intensive, easy to affect the human respiratory tract, etc., and achieve the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

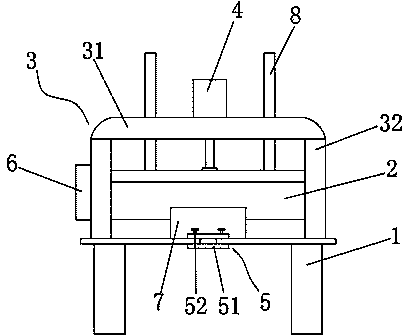

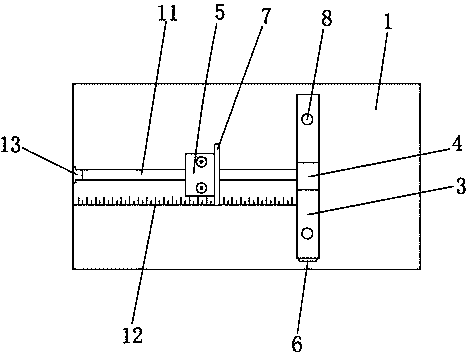

[0014] Such as figure 1 , 2 As shown, a paper cutting machine of the present invention includes a workbench 1, a cutting knife 2, a knife holder 3, a cutting knife driving device 4, a fixed distance slider 5 and a control panel 6 provided with control buttons. The blade of the cutting knife faces vertically downward and is installed on the worktable 1 through the knife holder 3. The cutting knife driving device 4 drives the cutting knife 2 to move downward. And the sliding groove 11 of the distance slider. A distance plate 7 is also provided on the distance slider 5 , and a scale notch 12 is also provided on the side of the slide groove 11 . Control panel 6 is installed on the knife rest side.

[0015] Wherein, the above-mentioned knife rest 3 comprises a beam 31 and two columns 32 whose lower ends are fixed on the workbench, the upper ends of the two columns are fixedly connected with the two ends of the beam 31 respectively, and the inner sides of the two columns 32 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com