Assembled framework beam-column joint adopting vertical connection and construction method thereof

A beam-column joint, prefabricated technology, applied in the processing of building materials, construction, building construction, etc., to achieve the effect of direct force transmission path, reliable joint connection, and simplified construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

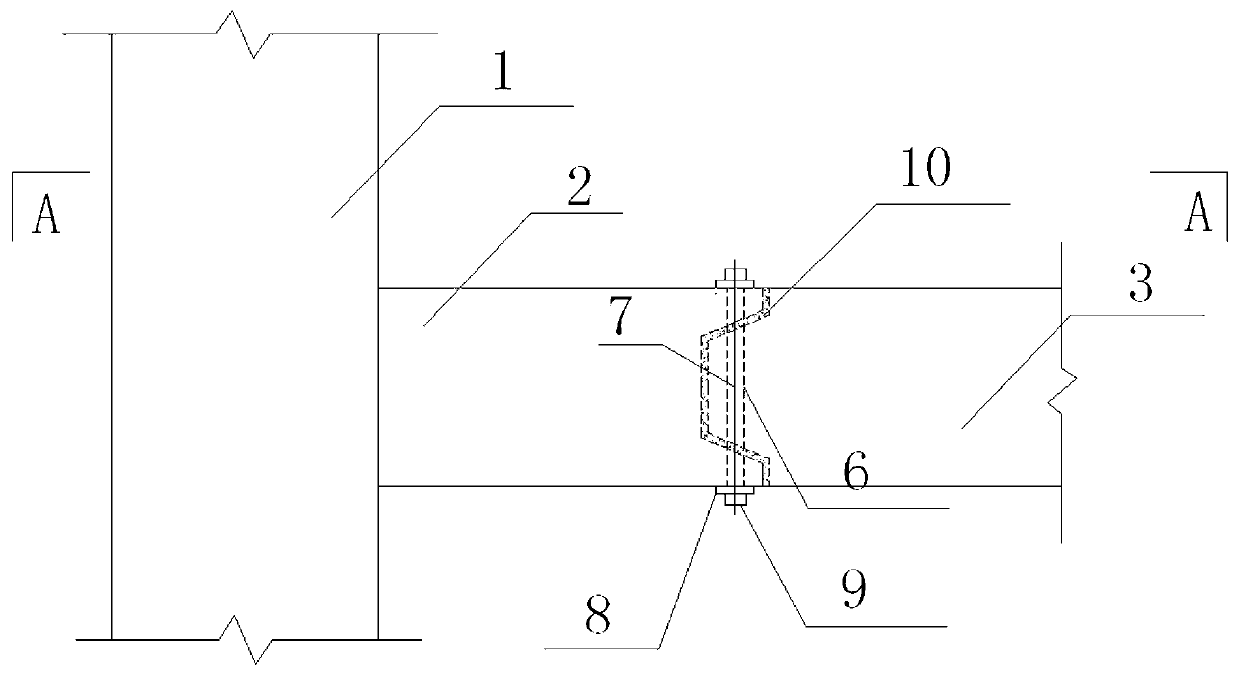

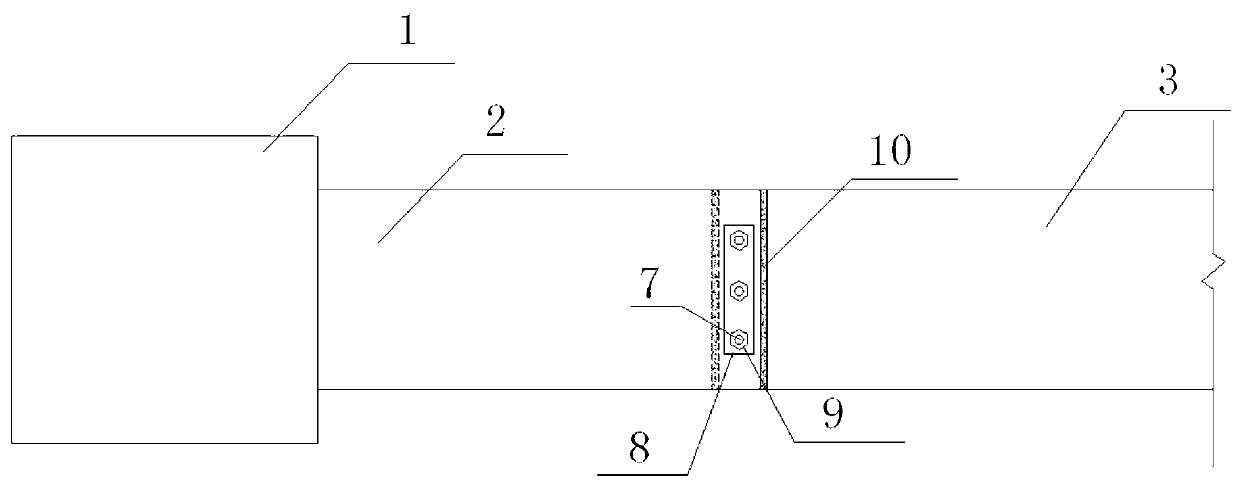

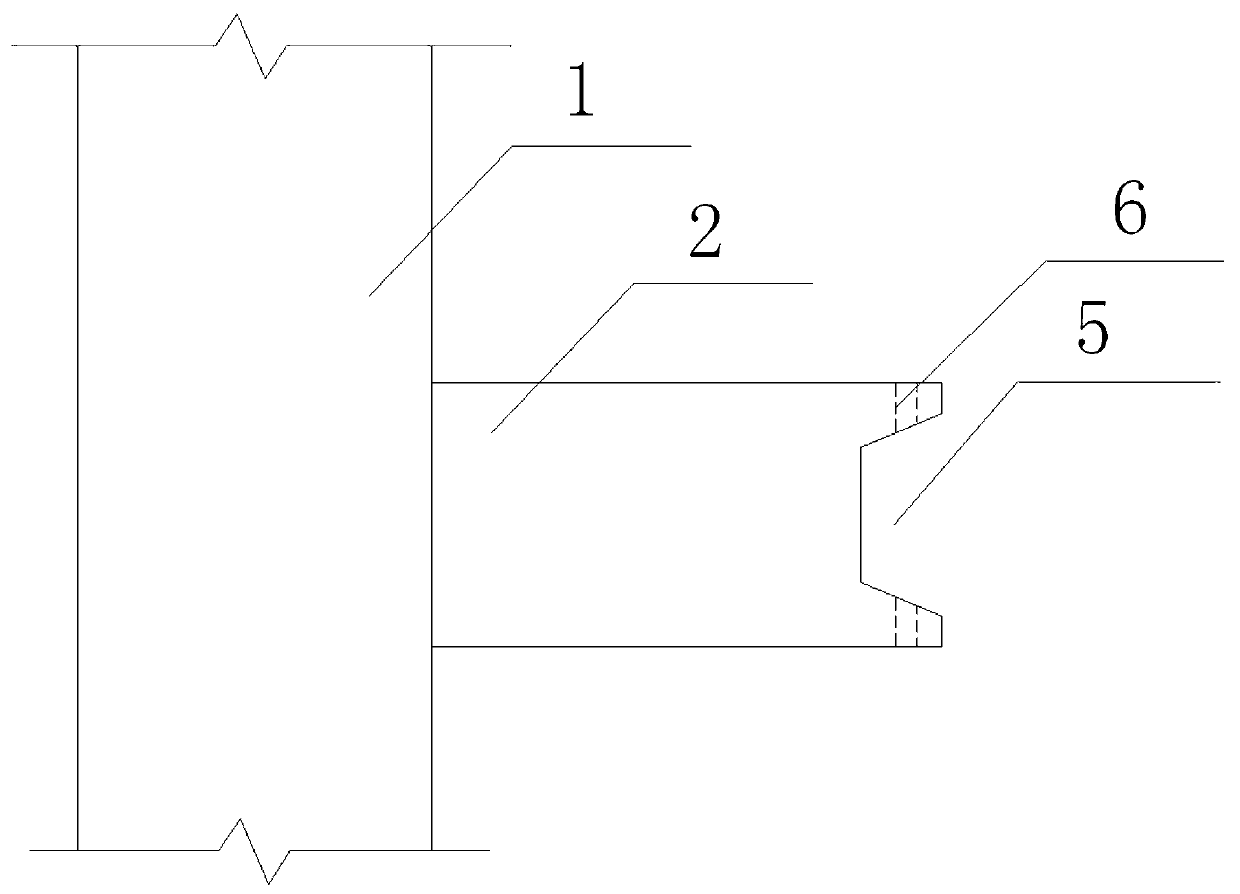

[0027] Example: such as Figure 1-4 As shown, a prefabricated reinforced concrete frame beam-column joint connected by vertical bolts includes the corbel 2 of the precast column 1 and the prefabricated beam 3, and the end face of the corbel 2 and the end face of the prefabricated beam 3 are respectively equipped with grooves 5. The bump 4 is provided with vertical corbel bolt holes 6 and prefabricated beam bolt holes 11 respectively; the cross sections of the groove 5 and the bump 4 are both trapezoidal or rectangular. The corbel 2 is embedded and fitted with the prefabricated beam 3 along the length direction of the prefabricated beam 3, and after being embedded, there are bolt backing plates 8 on the upper and lower sides, and the bolts 7 pass through the bolt backing plate 8, the corbel bolt holes 6, and the prefabricated The beam bolt hole 11 is fixed by the nut 9, so that the corbel 2 and the prefabricated beam 3 are connected as a whole, and the vertical shear force and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com