Moment resisting bi-axial beam-to-column joint connection

a moment-resisting connection and beam-to-column technology, applied in the direction of manufacturing tools, metal working equipment, welding/soldering/cutting articles, etc., can solve the problems of large vertical plane rotational demands of beam-to-column moment-resisting connections in steel frame buildings, rely on technically uncertain and costly means to transfer significant moment forces, and the method is self-limiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

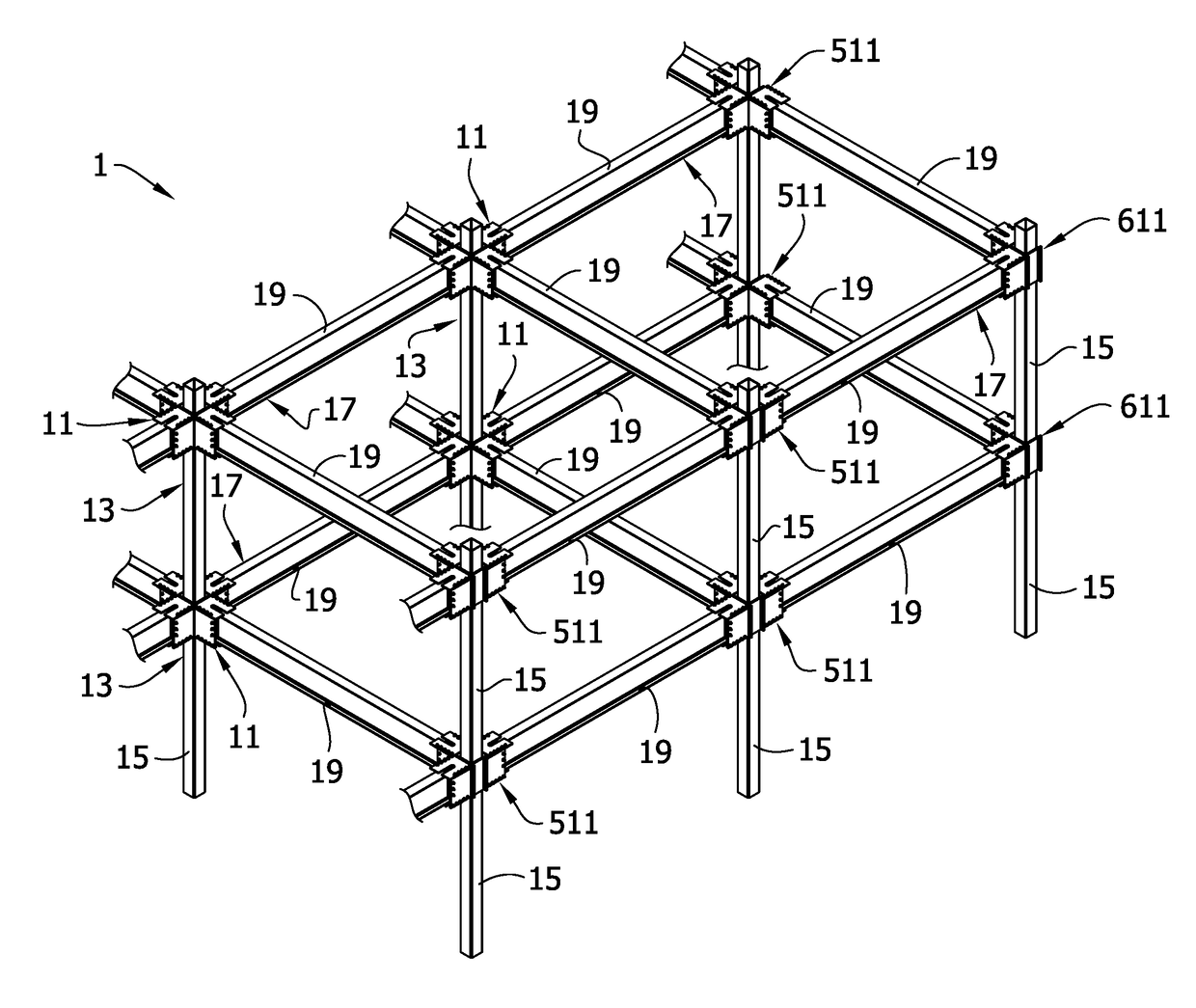

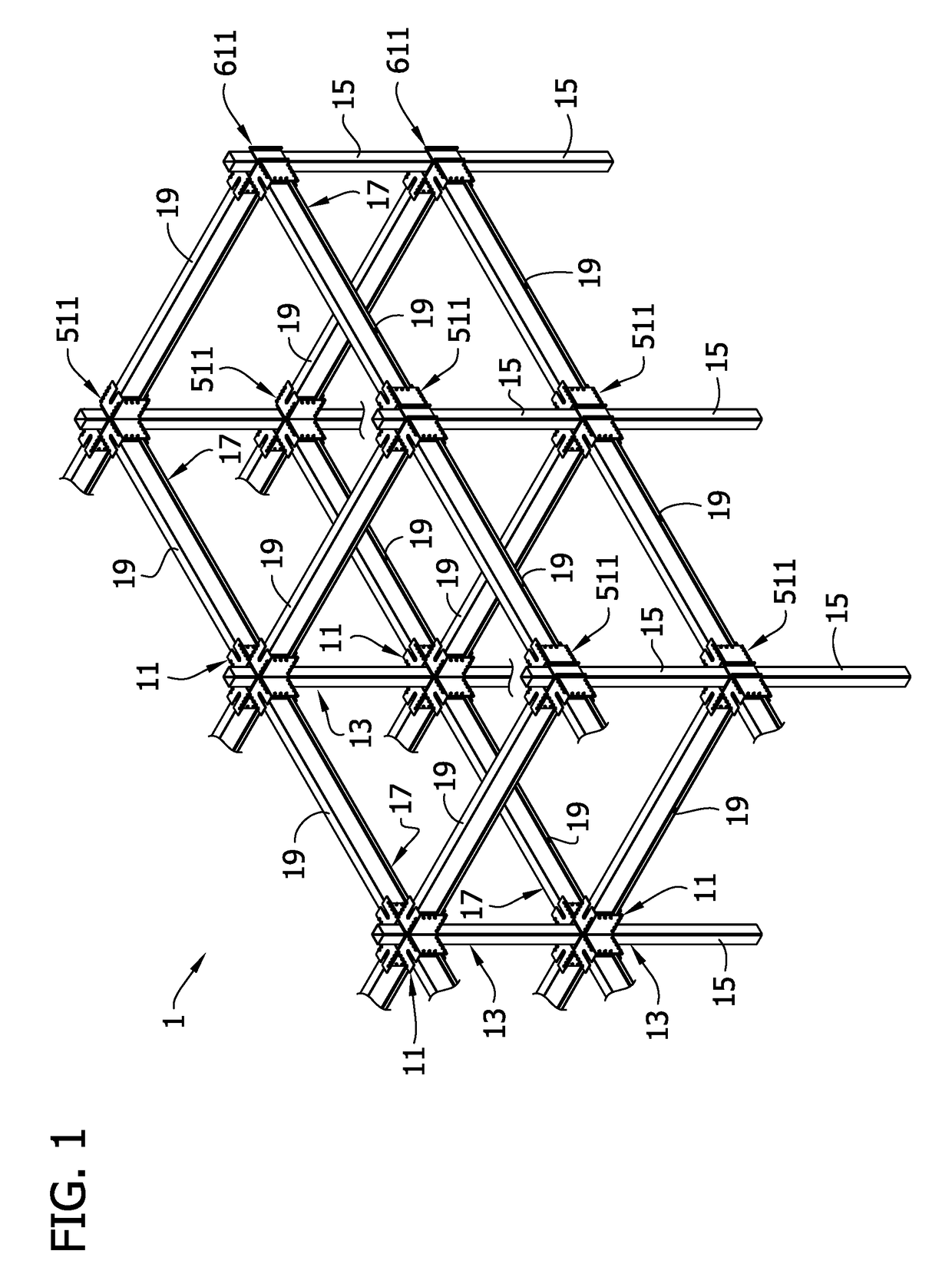

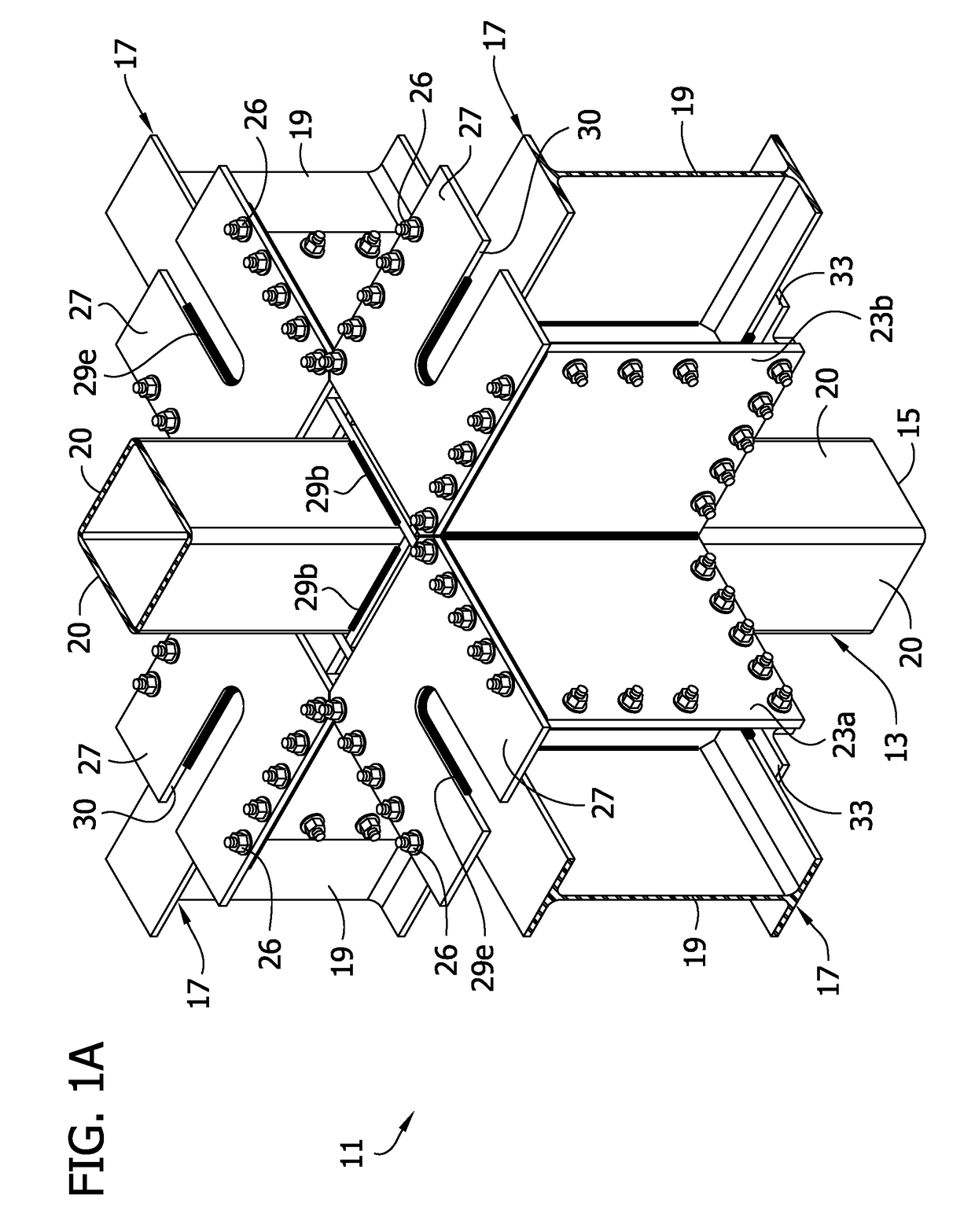

[0084]Referring to FIGS. 1-15, a bi-axial beam-to-column moment-resisting joint connection structure including a column assembly of a first embodiment is generally indicated at 11. The joint connection structure may be used in the construction of a building framework 1 (see, FIG. 1). In the illustrated embodiment, the joint connection structure joins a column assembly 13 including a column 15 to a plurality of full-length beam assemblies 17 each including a full-length beam 19. A full-length beam is a beam that has a length sufficient to extend substantially the full-length between adjacent columns in a structure (see, FIG. 2). Thus, a stub and link beam assembly as shown in FIGS. 5 and 16 of U.S. Pat. No. 6,138,427, herein incorporated by reference, is not a full-length beam. It will be understood that the beams 19 in FIG. 1A have been broken away, but are full-length beams. In the illustrated embodiment, the joint connection structure has a 4-sided / 4-beam configuration whereby fou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com