Dry type joggle frame structure

A dry-type mortise-joint frame and tenon-joint technology, which is applied in building construction, construction, etc., can solve the problem of poor connection performance between prefabricated wall panels or infill walls and frame beams and columns, and unfavorable static and dynamic performance of hidden corbel connections , The construction quality is not easy to be guaranteed, etc., to achieve the effect of reducing construction dust, simple force, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

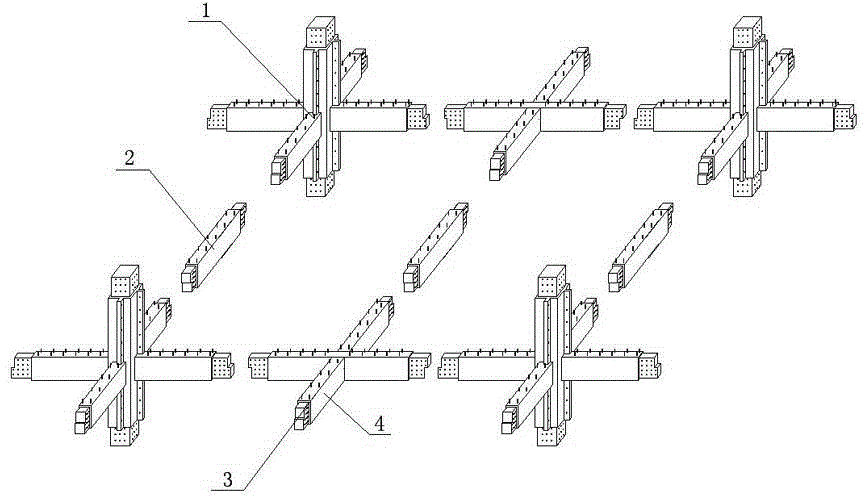

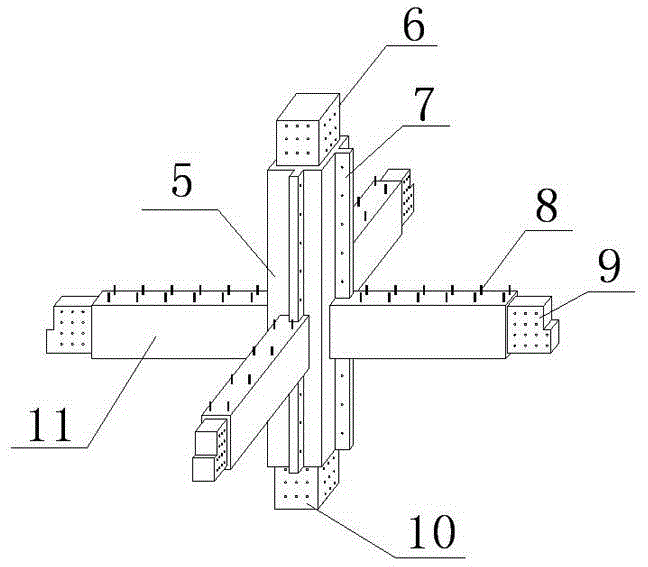

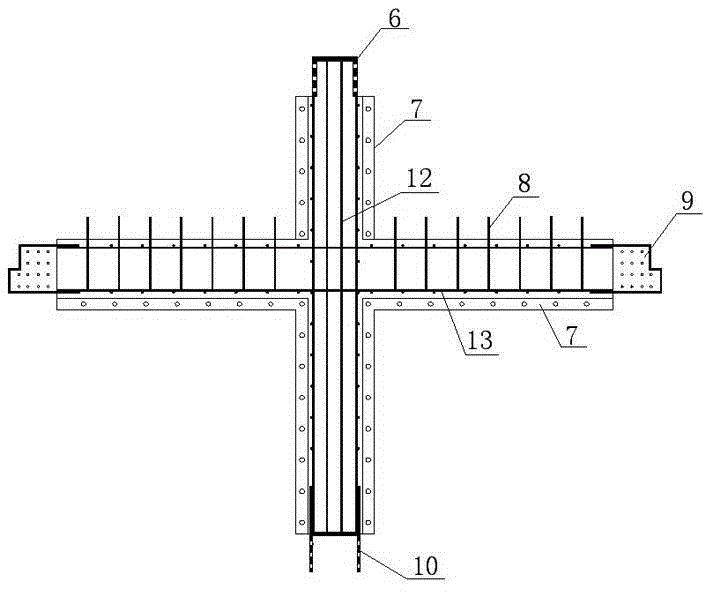

[0035] Refer to attached figure 1 , figure 2 and image 3 , a dry-type mortise-joint frame structure, including a beam-column joint component 1, the beam-column joint component 1 includes a prefabricated column 5 and a prefabricated beam 11 formed by pouring, and the prefabricated column 5 and the prefabricated beam 11 are prefabricated reinforced concrete components . The prefabricated column 5 is provided with a column longitudinal reinforcement 12, the prefabricated beam 11 is provided with a beam longitudinal reinforcement 13, the beam longitudinal reinforcement 13 passes through the column longitudinal reinforcement 12, and the beam longitudinal reinforcement 13 and the column longitudinal reinforcement 12 are integrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com