Self-reset beam column friction energy consumption node

A friction energy-consuming and self-resetting technology, applied in building components, building structures, earthquake-proof and other directions, can solve the problems of weak seismic performance, deformation damage, poor self-resetting ability, etc., to reduce the degree of damage, simple structure and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

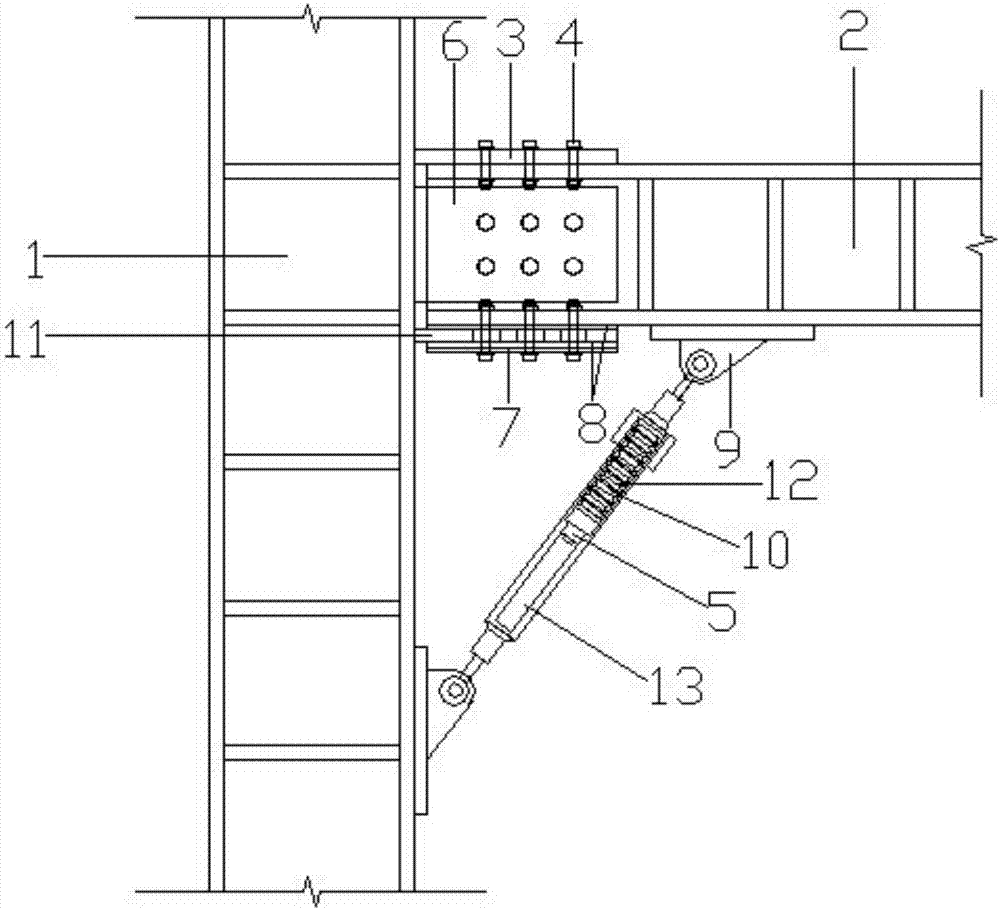

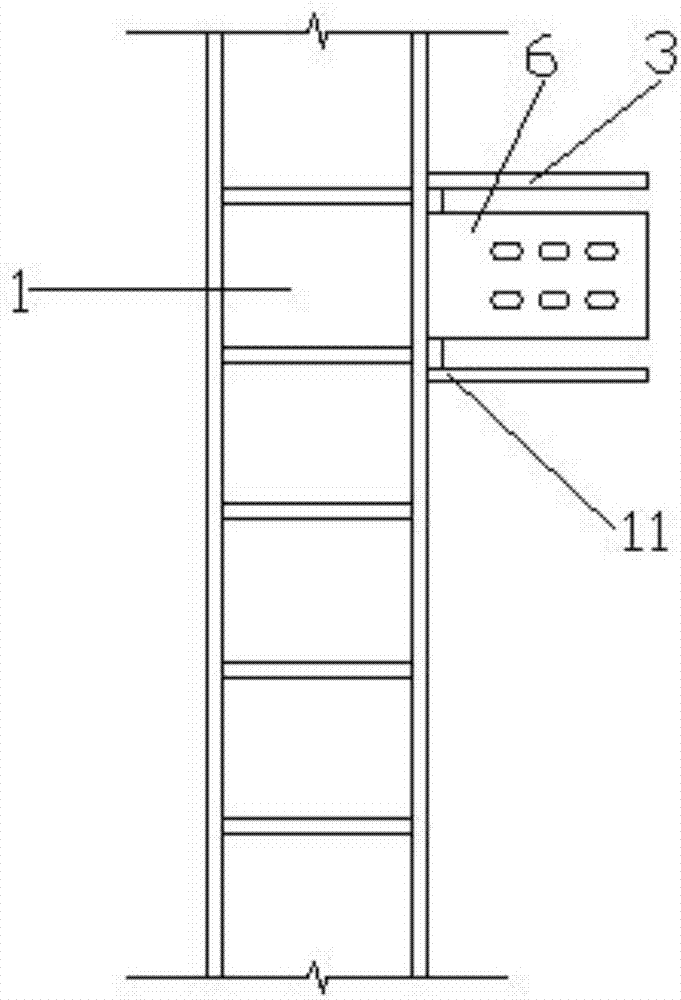

[0027] Such as Figure 1-2 As shown, the present invention provides a self-resetting beam-column frictional energy-dissipating node. The self-resetting beam-column frictional energy-dissipating node includes an upper flange plate 3, a lower flange plate 11, a web 6 and a self-resetting corner brace 10. The flange plate 3, the lower flange plate 11 and one end of the web plate 6 are all welded to the side of the steel frame column 1 to form a connecting short beam with a cavity in the middle, and the connecting short beam is used to connect the steel frame column 1 and the steel frame beam 2 . The steel frame column 1 and the steel frame beam 2 both have an I-shaped cross-section, and reinforcing ribs are evenly distributed on them. The web 6 is two pieces. The end of the steel frame beam 2 is inserted into the cavity of the connecting short beam, and the connecting short beam and the steel frame beam 2 are connected by high-strength bolts 4 . Both the lower flange plate 11 ...

Embodiment 2

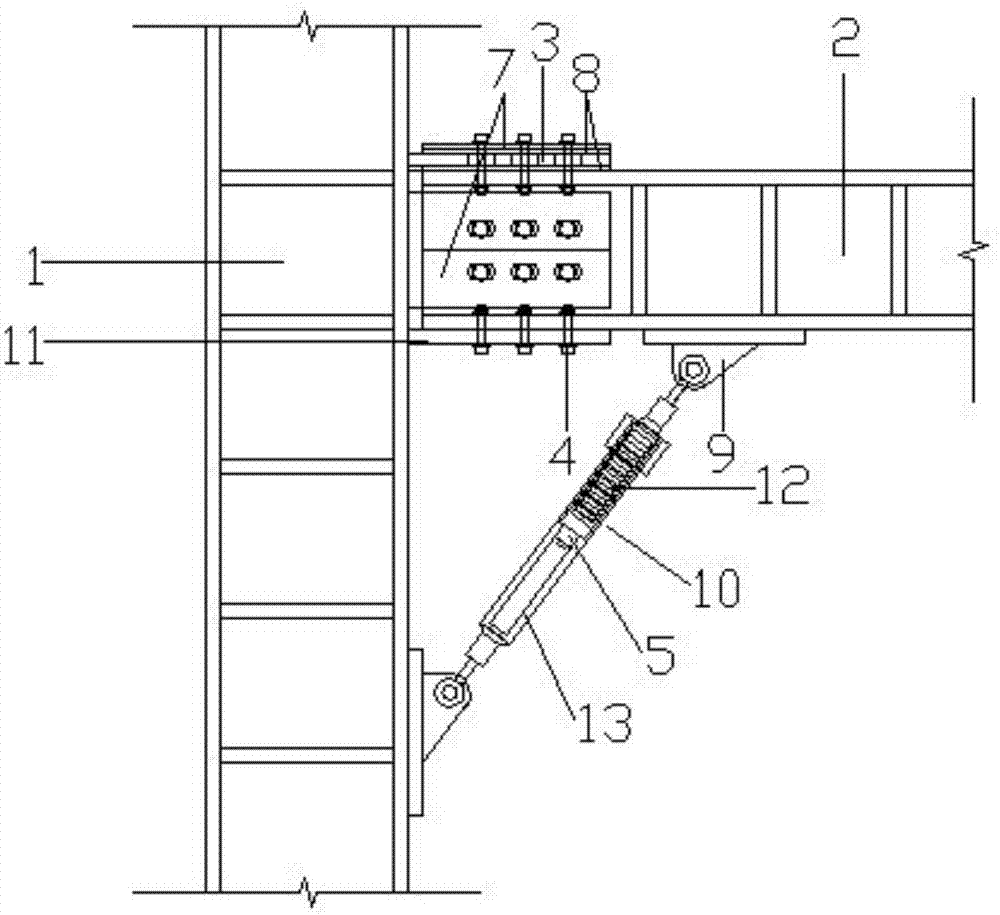

[0031] Such as Figure 3-4 As shown, a friction backing plate 8 is provided between the contact surface of the upper flange plate 3 and the steel frame beam 2, and a friction backing plate 8 is also provided between the contact surface of the upper flange plate 3 and the head of the high-strength bolt 4; A steel plate 7 is arranged between the plane where the friction pad 8 contacts the head of the high-strength bolt 4 . The connection position between the lower flange plate 11 and the steel frame beam 2 is not provided with a friction pad 8 . Other parts are the same as embodiment one.

[0032] The self-resetting corner brace 10 provided in the self-resetting beam-column frictional energy-dissipating node of the present invention can provide self-restoring force, has strong energy consumption and self-resetting ability, and has a simple structure and strong stability, so that the joint can be quickly restored after the earthquake initial state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com