Vehicle front-part structure

一种前部结构、汽车的技术,应用在下部结构、车辆部件、运输和包装等方向,能够解决无法吸收撞击能量、无法冲击吸收构件吸收撞击能量等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present invention will be described with reference to the above-mentioned drawings. The vehicle frame and beam in each embodiment are made of steel unless otherwise specified in advance.

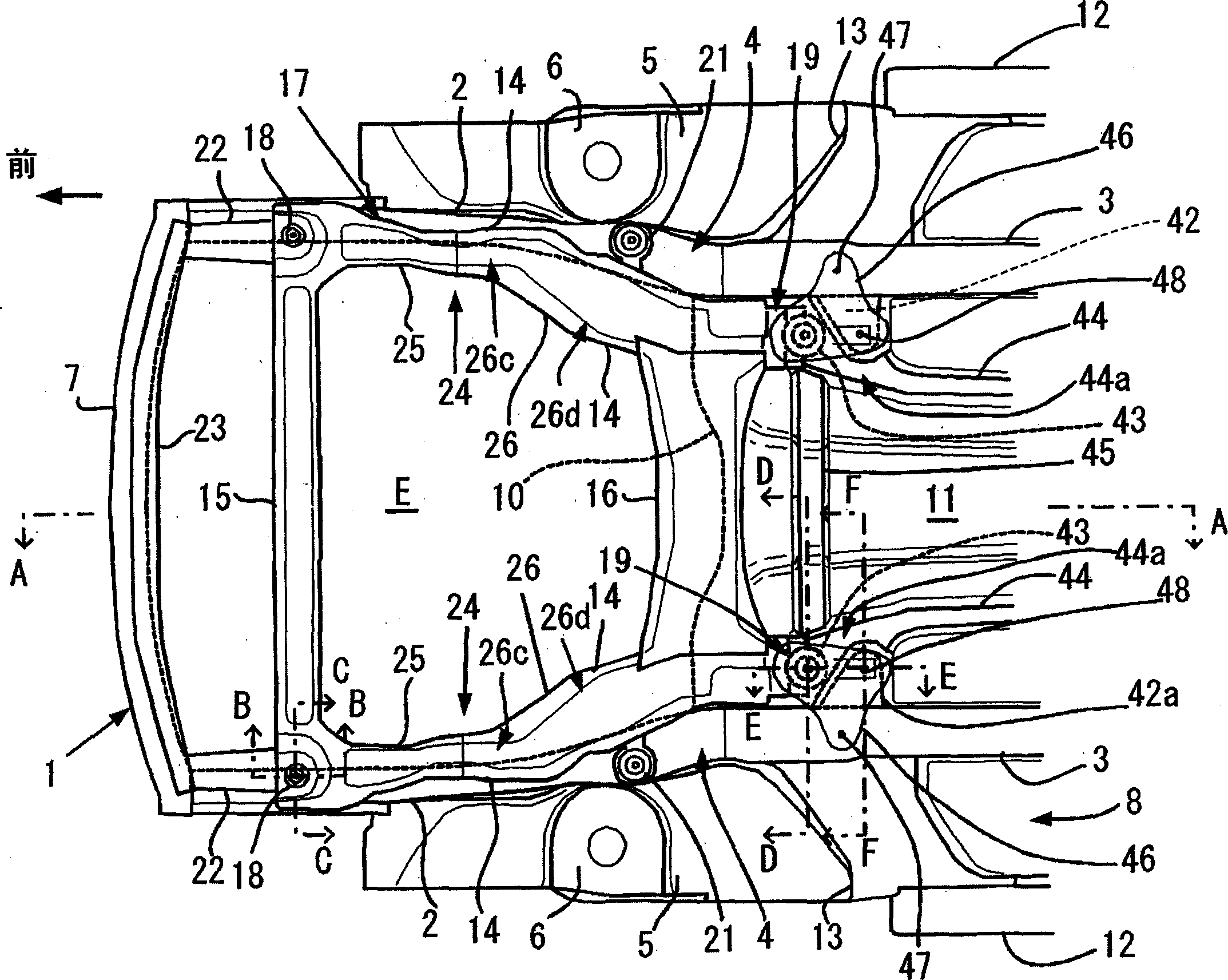

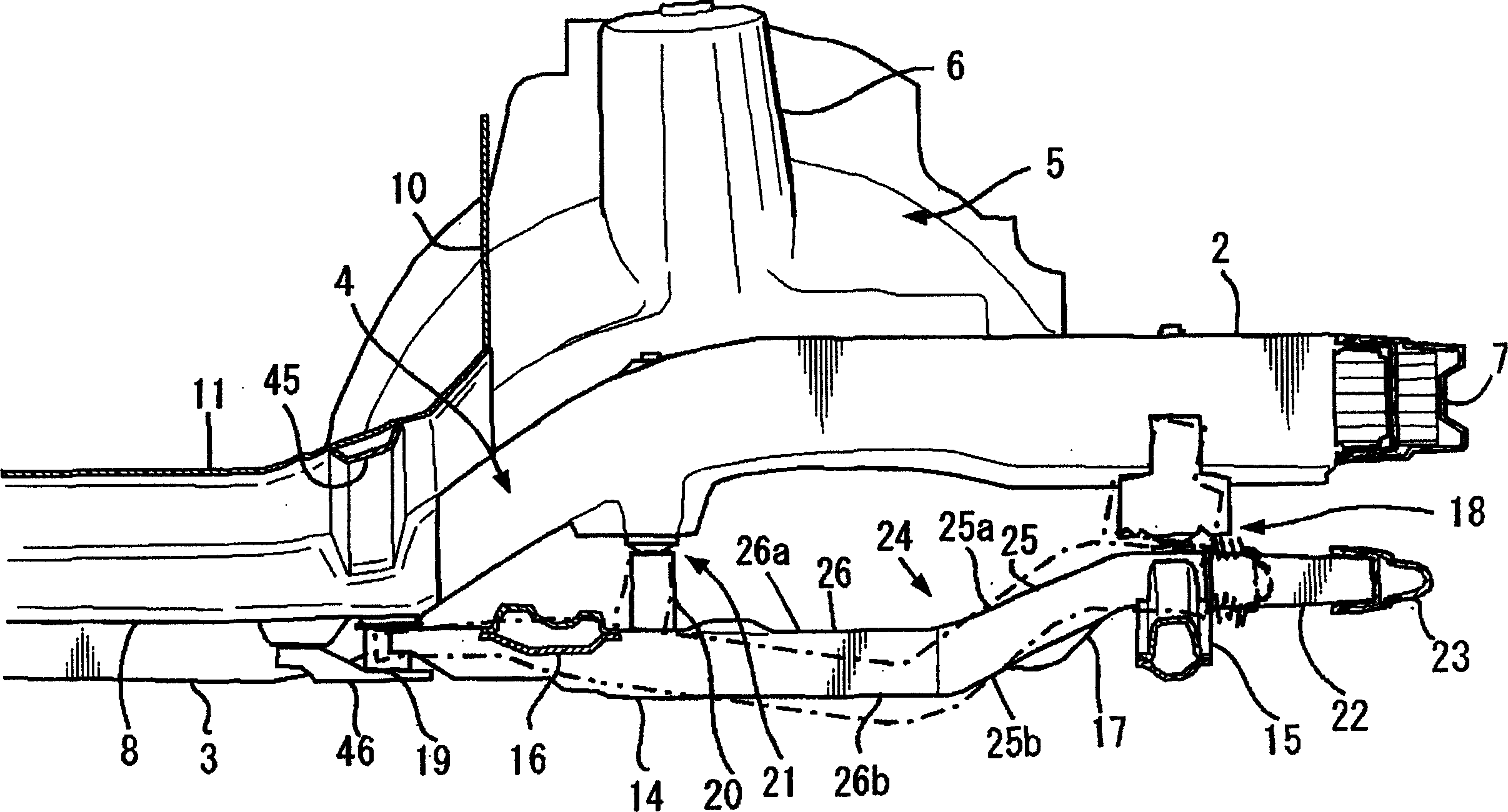

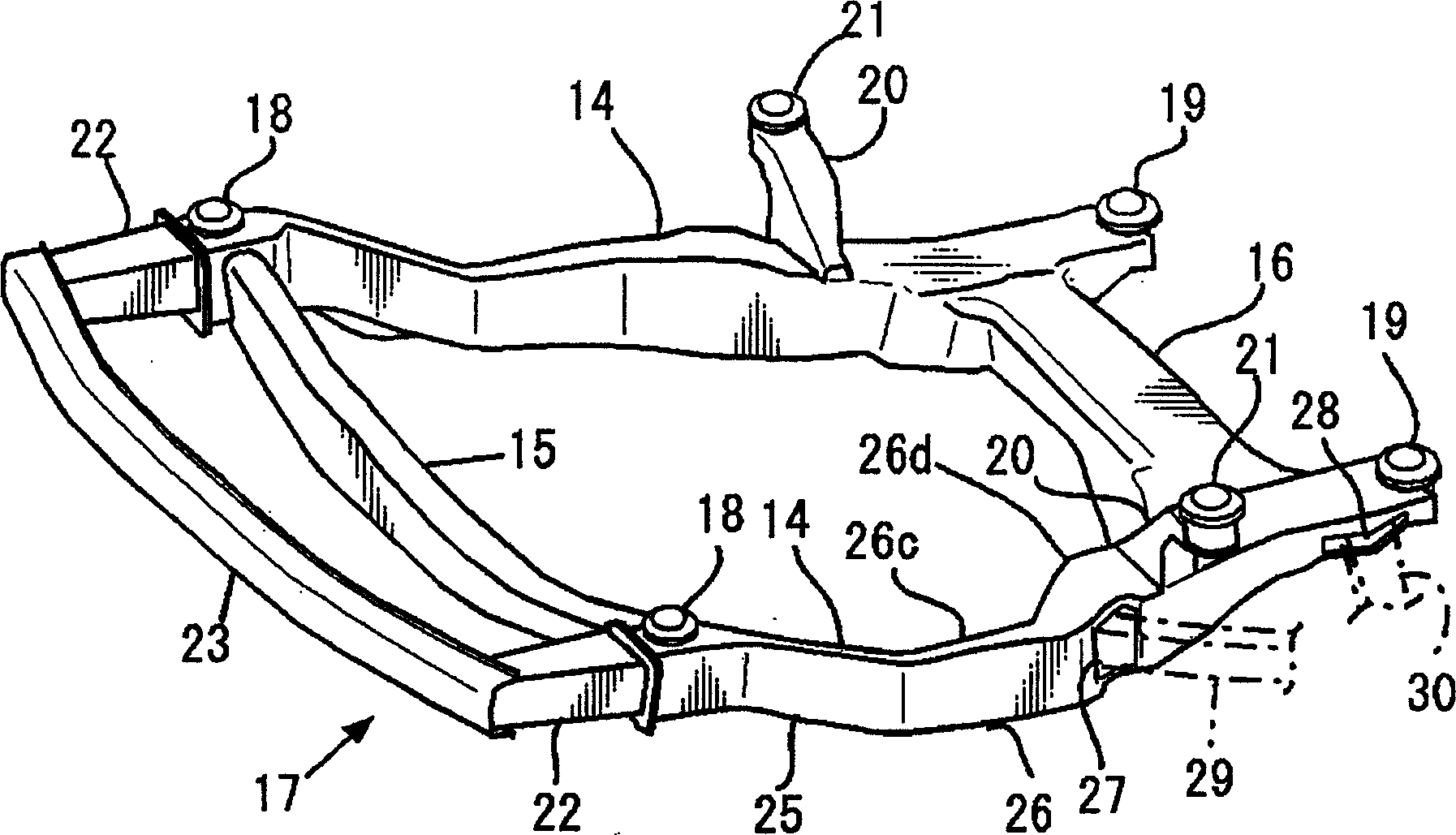

[0055] Such as figure 1 and figure 2 As shown, the vehicle frame 1 includes: a pair of left and right front side frames 2, 2 extending along the front and rear direction of the vehicle; Upwardly bent portions 4, 4 inclined rearward and downward are formed on the rear portions of the front side frames 2, 2, whereby the front ends of the front side frames 2, 2 are positioned higher than the bottom frame 3 by a certain degree.

[0056] Near the middle of the front side frames 2, 2 are formed adjacent to the outside of the vehicle, wheel housings 5, 5 for accommodating unillustrated front wheels, and near the center are formed upside-down shock absorbers for accommodating and supporting the front wheels. suspension tower) 6,6.

[0057] A bumper 7 made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com