Chemical leaching restoring method for soil polluted by heavy metals

A technology of contaminated soil and chemical leaching, which is applied in the field of chemical remediation of heavy metal-contaminated soil, can solve the problems of long cycle time, bacteria culture and difficulty in universal application, and achieve the effect of reducing heavy metals, reducing the number of residues, and high remediation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

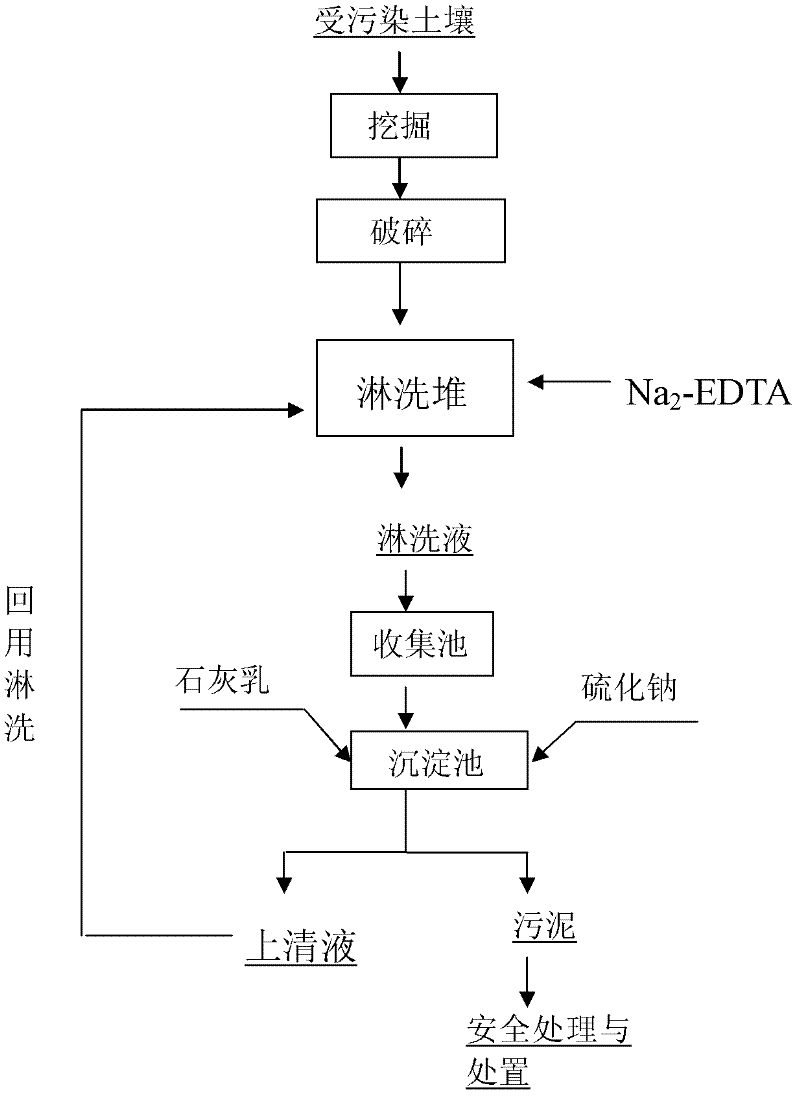

Method used

Image

Examples

Embodiment 1

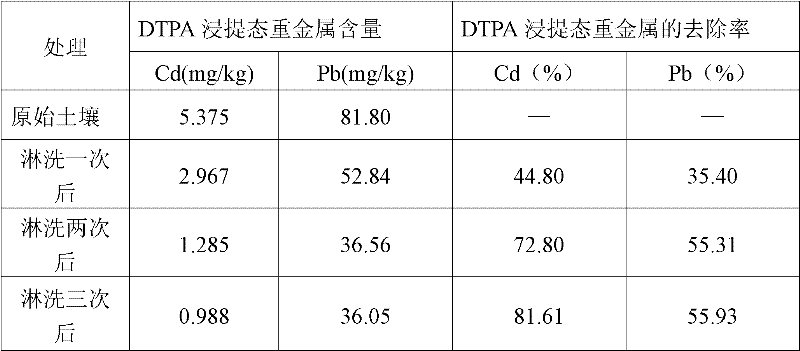

[0034]Example 1: Soil column leaching repairs cadmium lead polluted calcareous soil

[0035] Polluted soil in Dongdagou, Baiyin City, Gansu, was excavated and broken down to clods smaller than 2cm. Take 1 kg of crushed soil and put it into a plexiglass soil column with a diameter of 8 cm and a height of 30 cm, and the soil height is 20 cm. The bottom of the soil column is a plexiglass plate with a slope of 5 degrees and small holes to facilitate the drainage of seepage. Use a peristaltic pump with a flow rate of 100ml / h to pump 2L of Na with a concentration of 0.04mol / l 2 The EDTA solution was slowly rinsed from the top, and the filtrate was collected from the bottom of the soil column, and the contents of Cd and Pb in the filtrate were measured. The collected filtrate was washed with Ca(OH) 2 Adjust the pH to 10.0, then add solid Na according to 11 times the moles of Cd and Pb 2 S·9H 2 O, after standing for 40min, add PAM (0.3% polyacrylamide) at 6ml / l, stir, and filter....

Embodiment 2

[0040] Example 2: Field heap leaching repairs cadmium lead polluted calcareous soil

[0041] The polluted soil in Dongdagou, Baiyin City, Gansu Province was broken into clods less than 2cm by excavation and rotary tillage. The crushed soil was built into a mound of 12.5 tons (6×8×0.2m), and plastic was laid under the mound to prevent leakage. The flow rate is 1.5m 3 / h acid-resistant pump extracts Na with a concentration of 0.04mol / l 2 EDTA solution is slowly rinsed from the top, and the amount of rinse agent is 25M 3 . The filtrate was collected from the bottom of the mound, and the content of Cd and Pb in the eluate was determined. Filtrate with Ca(OH) 2 Adjust the pH to 10.0, then add solid Na according to 11 times the total moles of Cd and Pb 2 S·9H 2 O, after standing for 40min, add PAM (3% polyacrylamide) at 6ml / l and stir to clarify. The supernatant continued to wash the soil through the peristaltic pump, and the above steps were repeated for 3 times to wash the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com