Wall rendering robot

A technology of robots and walls, which is applied in the direction of construction and building construction, can solve the problems of heavy weight of the whole machine, inconvenience of going up and down stairs, and unsafety, and achieve the effects of convenient installation and debugging, reduction of weight of the whole machine, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

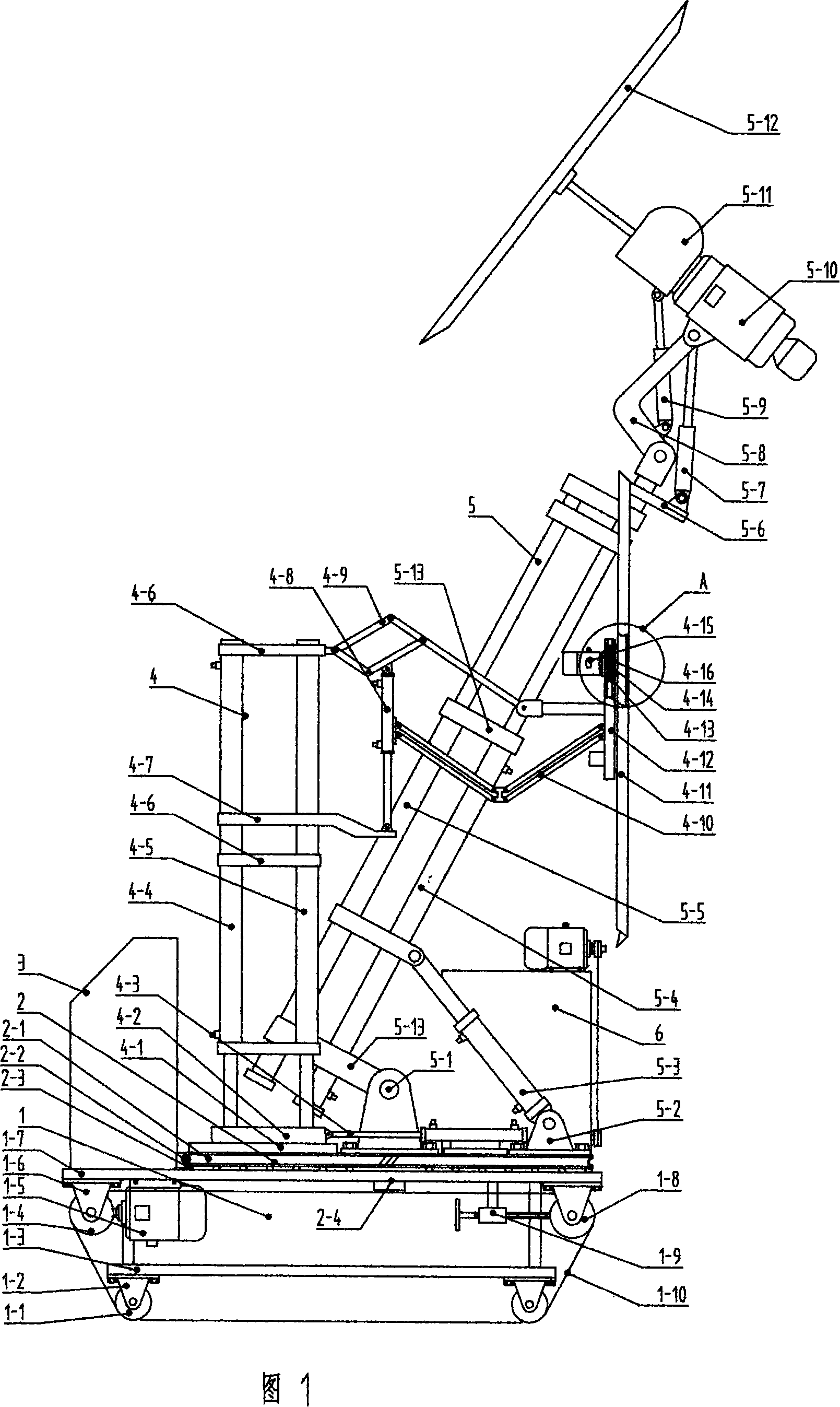

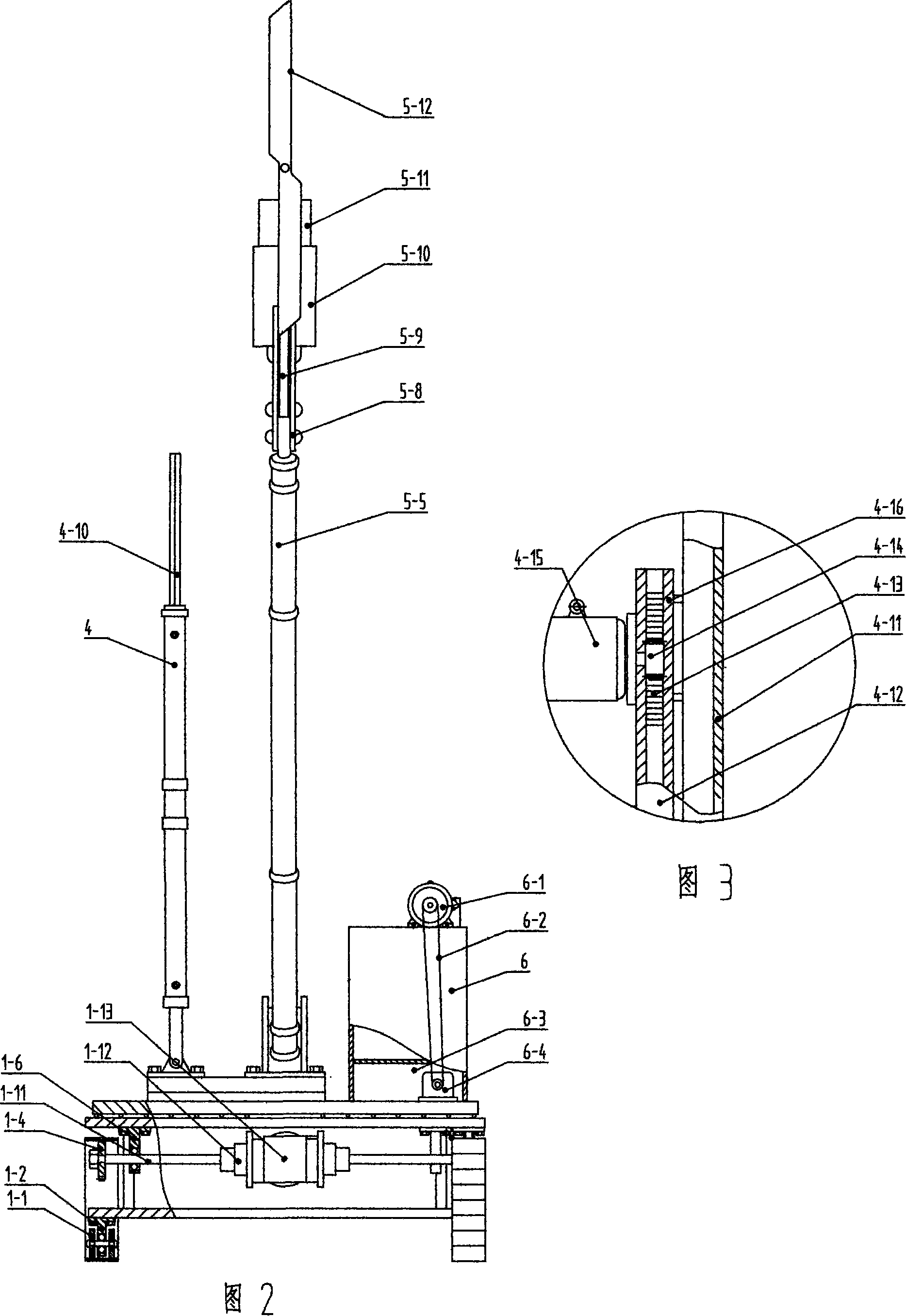

[0025] As shown in Figure 1, Figure 2, and Figure 3, a wall painting robot includes a crawler chassis 1, a slewing support 2 installed on the upper part of the crawler chassis 1, an operation box 3, and a yin and yang corner wiper installed on the upper end of the slewing support 2. Ash device 4, planar ash transfer device 5 and hydraulic power unit 6; the crawler chassis 1 includes a steel structure rectangular vehicle frame 1-3, a traveling wheel 1-1 mounted on the lower end of the frame 1-3 through a bracket 1-2 , the frame panel 1-7 fixed on the upper end of the frame 1-3, the driving gear 1-4 installed on the bottom of the frame 1-2, the guide wheel 1-8, the motor 1-5, the gearbox 1-13, the crawler belt Tensioning device 1-9 and crawler belt 1-10; described slewing bearing 2 includes the turntable 2-1 that is installed on the vehicle frame panel 1-7 through the sliding fit of the central shaft, the motor that drives the turntable 2-1 to rotate, and the gearbox ; The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com