Method for forming carbon fiber composite parts with large shaft-to-diameter ratio

A composite material and carbon fiber technology, which is used in the field of forming carbon fiber composite material parts with a large axis-to-diameter ratio, can solve the problems of inability to guarantee the straightness of the forming cable, unfavorable for the tensile strength of carbon fiber, operation repeatability, poor stability, etc. , to achieve the advantages of excellent mechanical properties, stable and consistent performance, and easy guarantee of straightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is not limited to the following specific embodiments. Those skilled in the art can implement the present invention in various other specific embodiments according to the disclosed content of the present invention, or make simple changes or All changes fall within the protection scope of the present invention. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

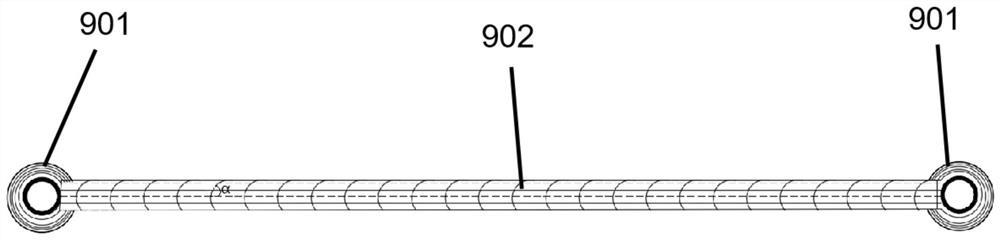

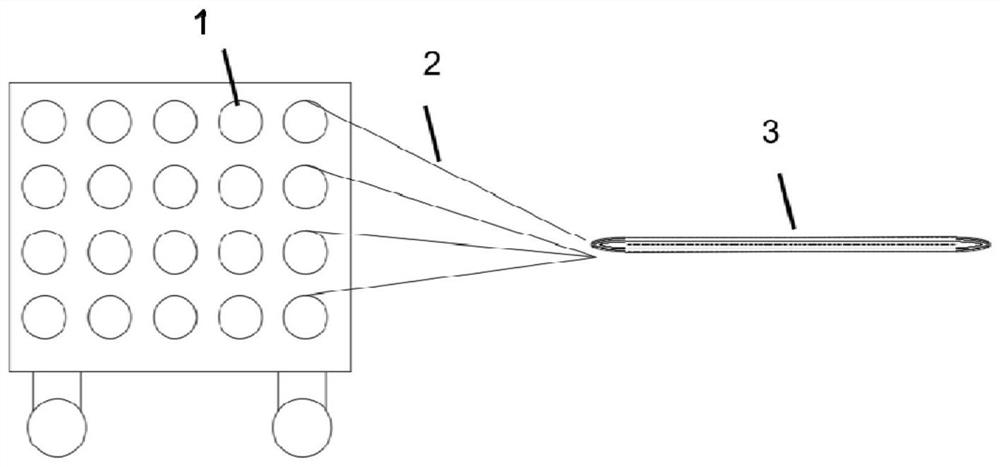

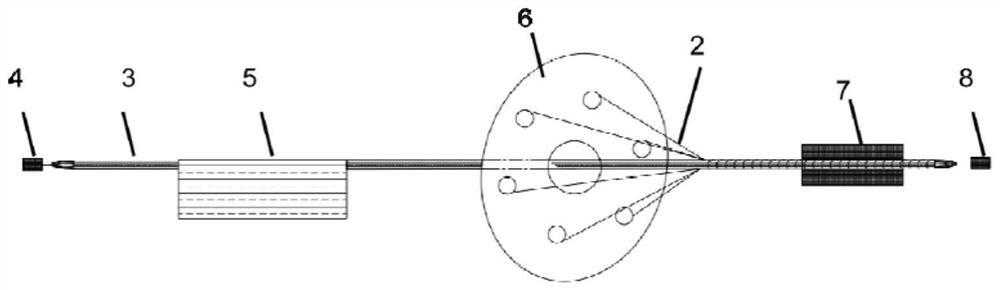

[0036] The present invention is described in further detail below in conjunction with embodiment: see Figure 2 to Figure 5 , a method for forming carbon fiber composite parts with a large shaft-to-diameter ratio, see figure 1 The carbon fiber composite material part includes an intermediate rod part and ring parts integrally formed at both ends of the rod part, and the forming method of the carbon fiber composite material part comprises the following steps:

[0037] (1) see fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com