Walking-type hanging basket for transmission line

A transmission line, walking technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of long construction time, inability to stand construction, construction blind spots, etc., and achieve the effect of improving operation efficiency, reducing labor intensity and shortening construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

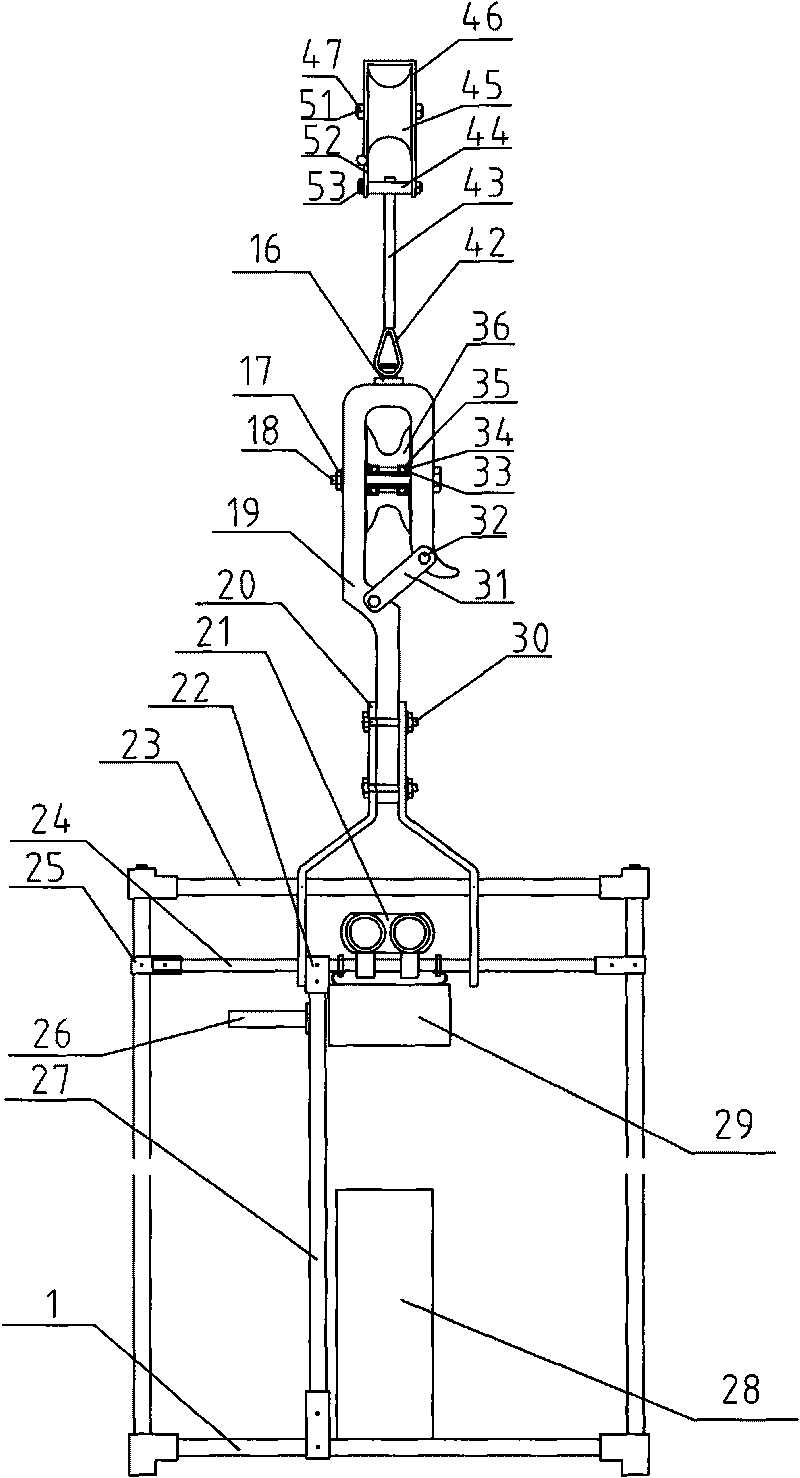

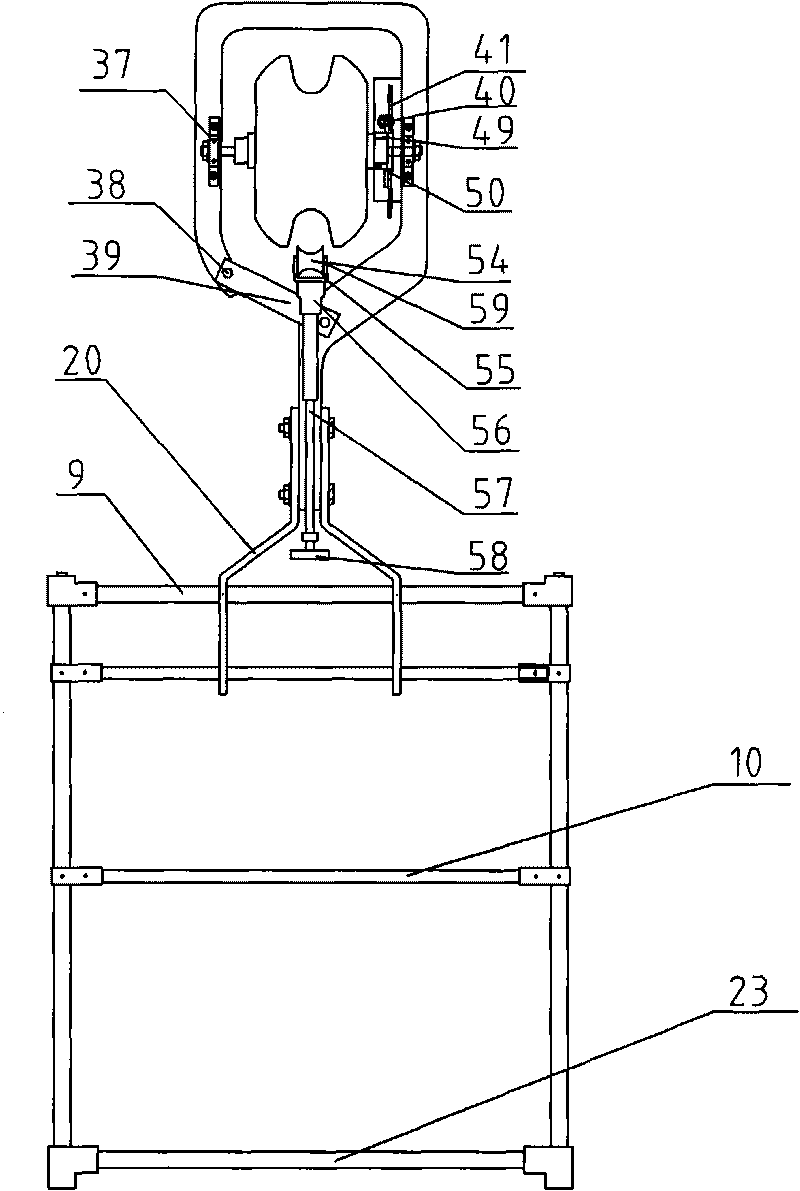

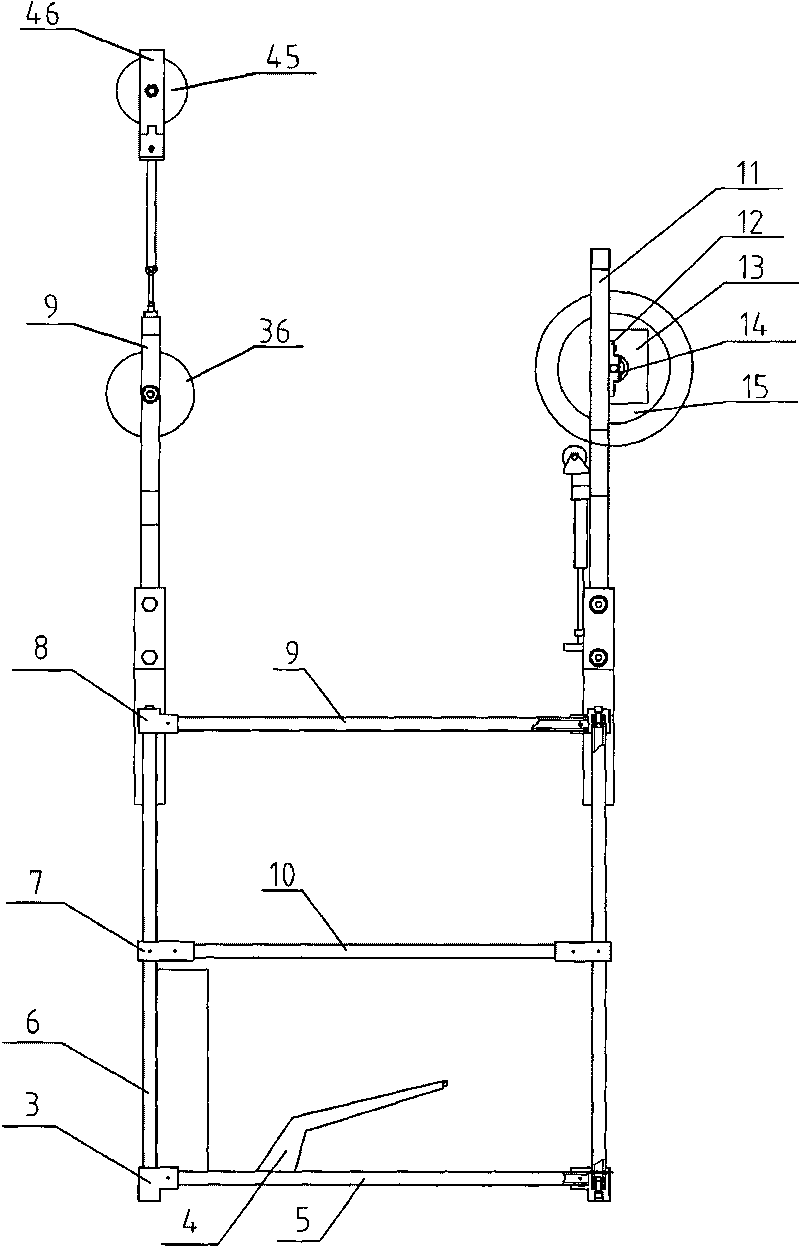

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0019] As shown in the figure: the walking hanging basket of the transmission line includes a basket chassis formed by combining the lower beam 1 of the basket frame, the lower longitudinal beam 5 of the basket frame and the tee joint 3 at the lower part of the basket frame, the upper cross beam 23 of the basket frame, the basket frame upper The vertical beam 9 on the upper part of the frame and the tee joint 8 on the upper part of the basket are combined to form the top frame of the basket frame. Frame thin two-way joint 25, on the basket thin two-way joint 25, be connected with basket middle crossbeam 24, be positioned at the basket middle crossbeam 24 of one side and basket upper crossbeam 23, drive wheel frame 11 is installed, driving wheel The frame 11 is provided with a driving wheel device, and the driving wheel frame 11 is provided with an auxiliary ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com