Ultrathin metal plate heat-insulation reflection coating and its preparation method

A technology of heat insulation reflection and metal plate, applied in the field of coatings, can solve the problems of inability to achieve pre-coating and large-scale factory production, can not achieve good decorative effects, restrict the use range of heat insulation coatings, etc., and shorten the construction time , a wide range of applications, the effect of thin coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

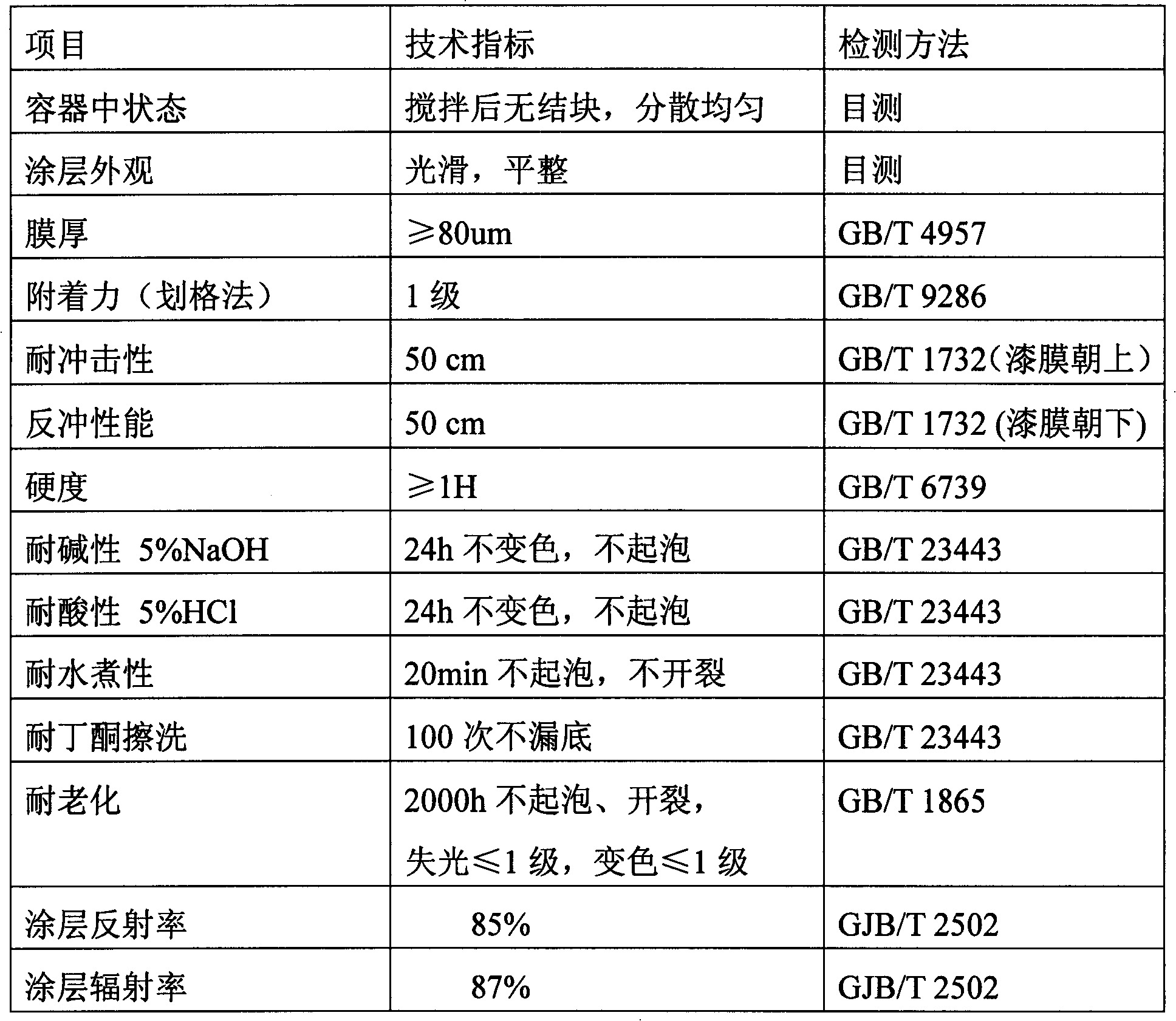

Examples

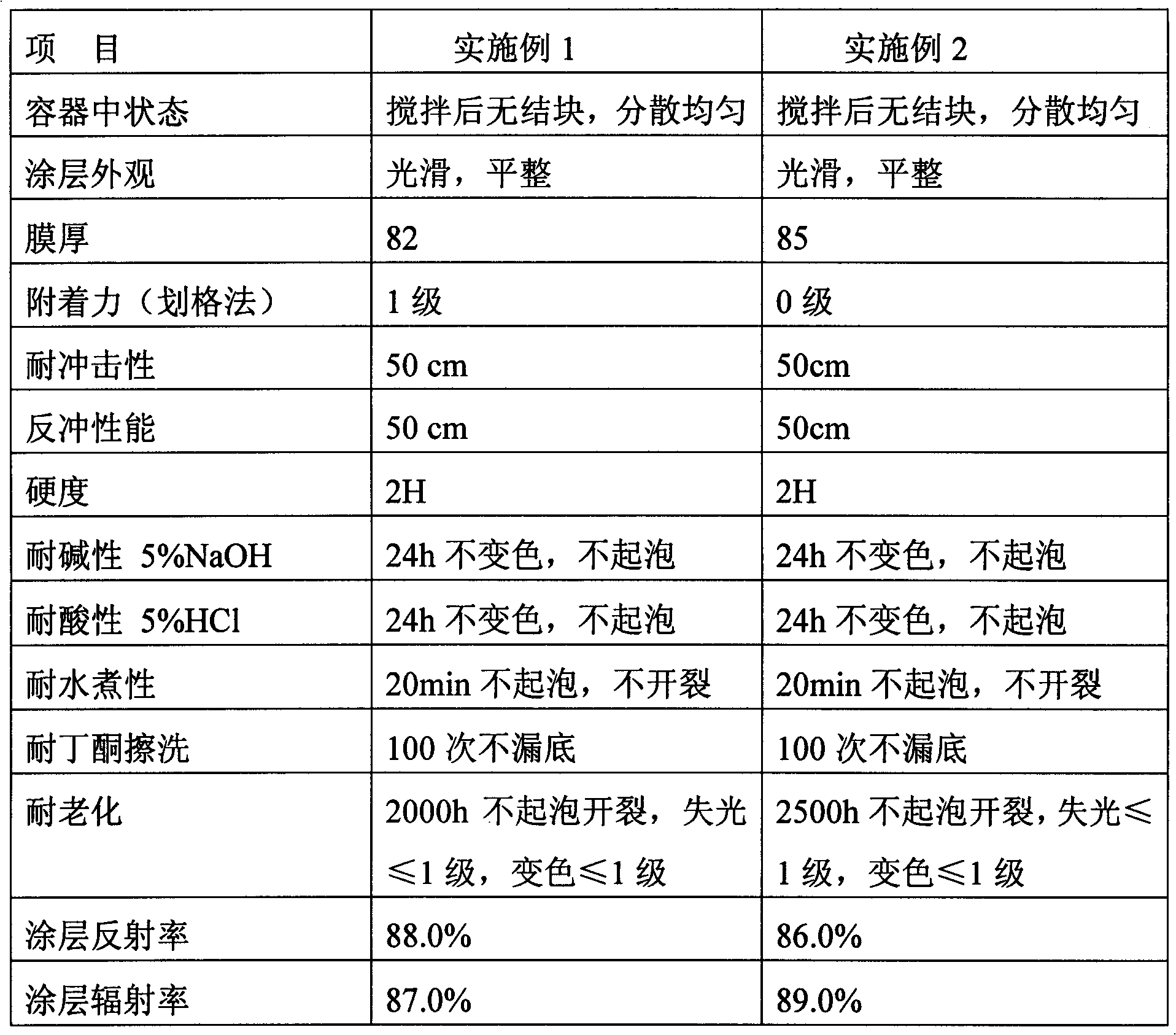

Embodiment 1

[0060] A method for preparing an ultra-thin metal plate heat-insulating reflective coating, the method comprising the following steps:

[0061] Insulation paint primer

[0062] component name

parts by weight

[0063] polyester resin

43.0

10.0

4.5

Adipate high boiling point solvent

3.0

Bentonite Thixotropic Agent

0.5

D

1.5

Dispersant

1.5

leveling agent

0.5

0.5

Titanium dioxide

25.0

5.0

Methylated melamine resin

5.0

[0064] Insulation paint finish

[0065] component name

parts by weight

Fluorocarbon resin

30.0

Acrylic

15.0

8.0

Adipate high boiling point solvent

5.0

D

1.5

Dispersant

2.0

leveling agent

0.5

27.0...

Embodiment 2

[0072] A method for preparing an ultra-thin metal plate heat-insulating reflective coating, the method comprising the following steps:

[0073] Insulation paint primer

[0074] component name

parts by weight

epoxy resin

52.0

9.0

4.0

Adipate high boiling point solvent

3.0

Bentonite Thixotropic Agent

0.5

Dispersant

1.5

leveling agent

0.5

0.5

Titanium dioxide

20.0

4.0

Methylated melamine resin

5.0

[0075] Insulation paint finish

[0076] component name

parts by weight

Acrylic

50.0

[0077] Xylene

8.0

Adipate high boiling point solvent

5.0

D

1.5

Dispersant

2.0

leveling agent

0.5

22.0

6.0

Clos...

Embodiment 3

[0088] An ultra-thin metal plate heat-insulating reflective coating, the coating includes a primer and a top coat, using double-coating, the metal plate is first coated with a primer, and then a top coat, wherein:

[0089] 1) Preparation of primer

[0090] (a) after 40 weight parts of film-forming resin epoxy resins are dropped into stirring tank earlier, add solvent propylene glycol methyl ether acetate 20 weight parts, stir;

[0091] (b) Add 0.5 parts by weight of polyamide wax as a thixotropic agent, stir at a high speed for 0.5 hours, check whether the thixotropic agent has been stirred evenly, if there is no particle, it means that it is evenly stirred, and then add other additives: 1 part by weight of a commercially available dispersant , 1 weight part of wetting agent, 1 weight part of defoamer, 2 weight parts of leveling agent, and stir evenly;

[0092] (c) adding 20 parts by weight of pigment rutile titanium dioxide in proportion, stirring for 0.5-1 hour, until the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com