Water-in-water colored sand wall texture coating and preparation method thereof

A technology of texture paint and sand wall shape, which is applied in the field of water-in-water colorful sand wall texture paint and its preparation, and can solve the problems of increased construction cost, high paint consumption, and poor simulation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

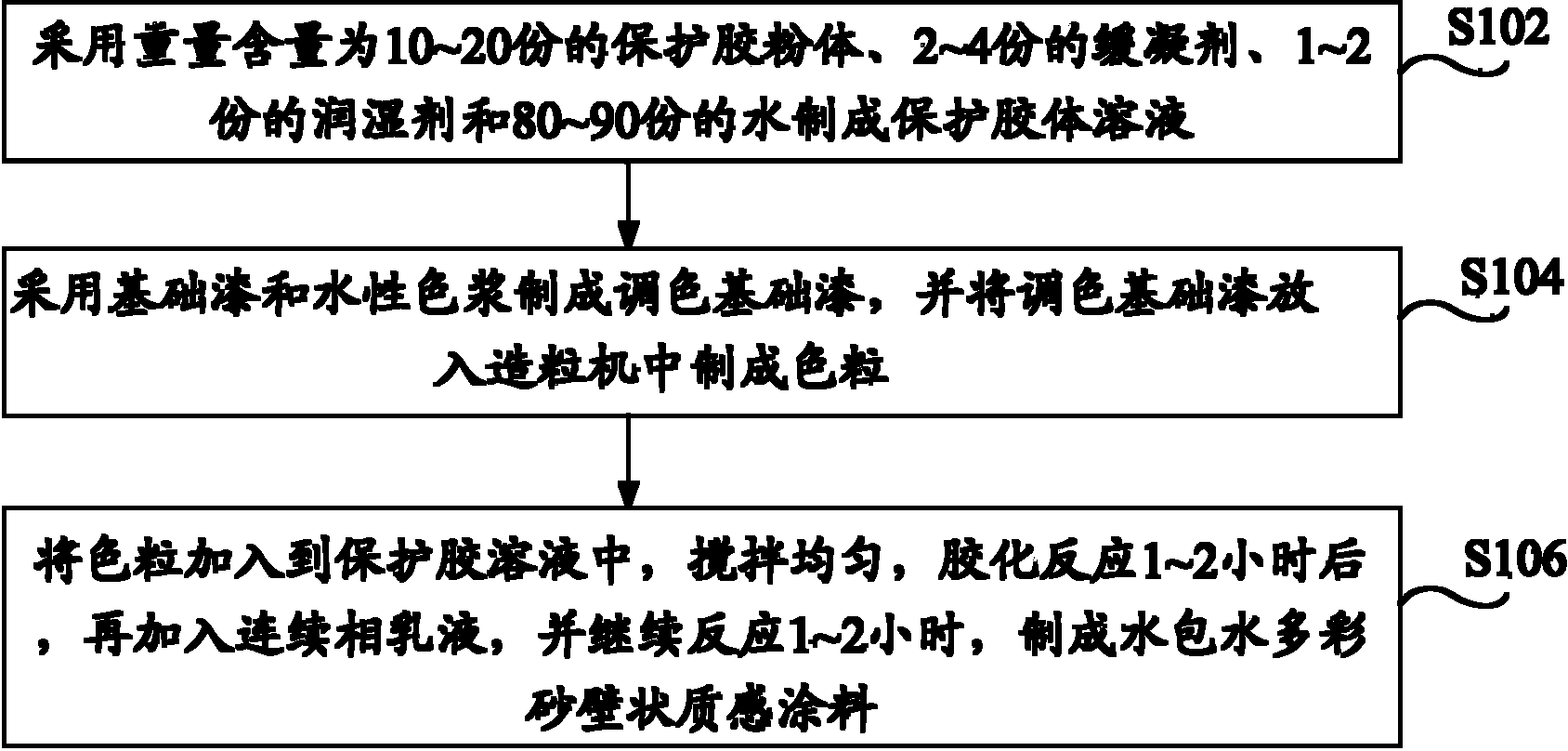

[0070] Such as figure 1 As shown, another embodiment of the present invention provides a method for preparing a water-in-water colorful sand wall-like texture paint, which can be used to prepare the water-in-water colorful sand wall-like texture paint described in any of the above embodiments, comprising the following steps :

[0071] Step S102, preparing protective colloid solution: using 10-20 parts by weight of protective colloid powder, 2-4 parts of retarder, 1-2 parts of wetting agent and 80-90 parts of water to prepare the Protective colloid solution;

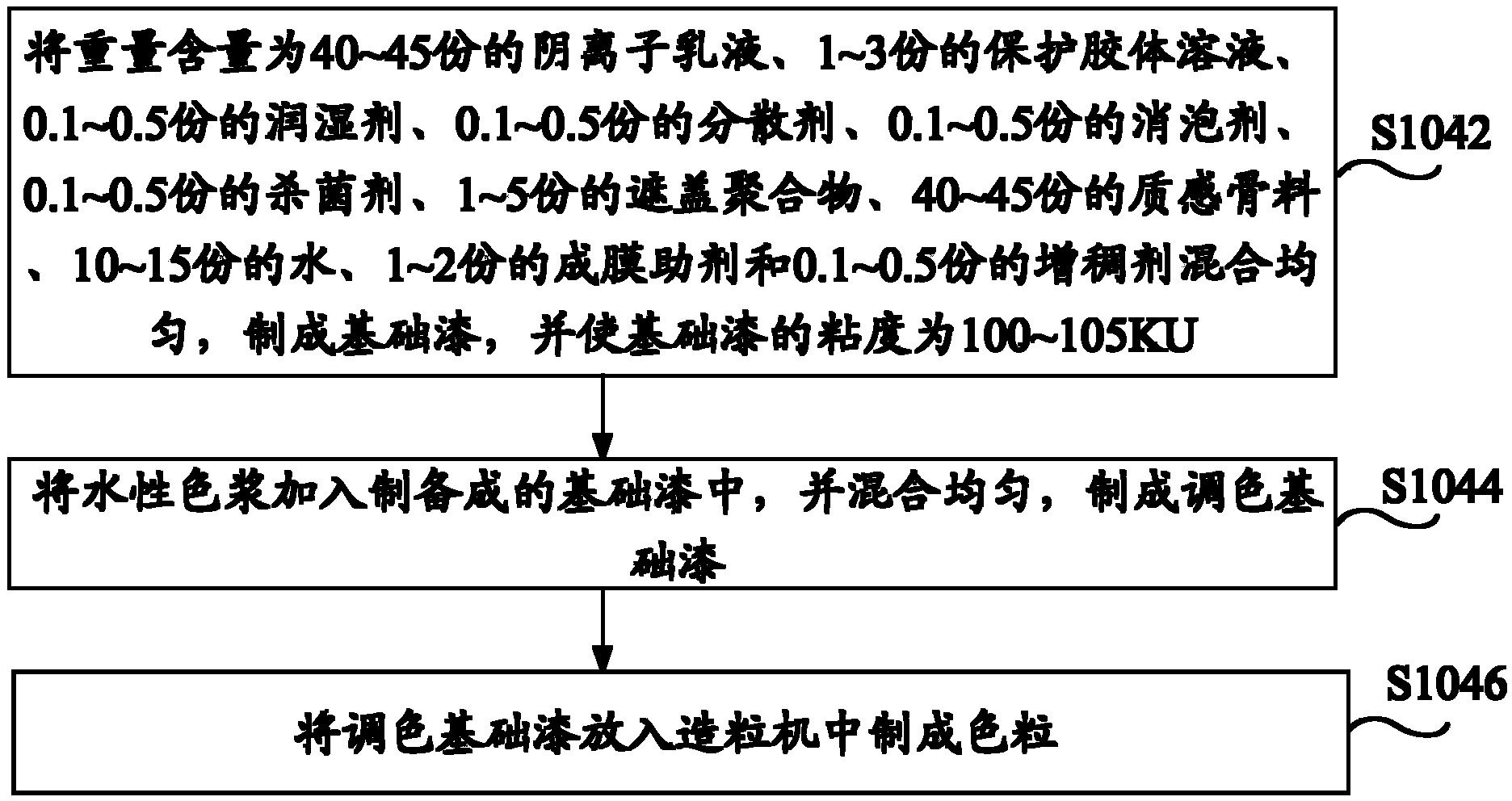

[0072] Step S104, preparing the toning base paint: using the base paint and water-based color paste to prepare the toning base paint, and putting the toning base paint into a granulator to make color granules;

[0073] Step S106, adding the color particles into the protective colloid solution, stirring evenly, after gelation reaction for 1-2 hours, then adding the continuous phase emulsion, and continuing the reaction f...

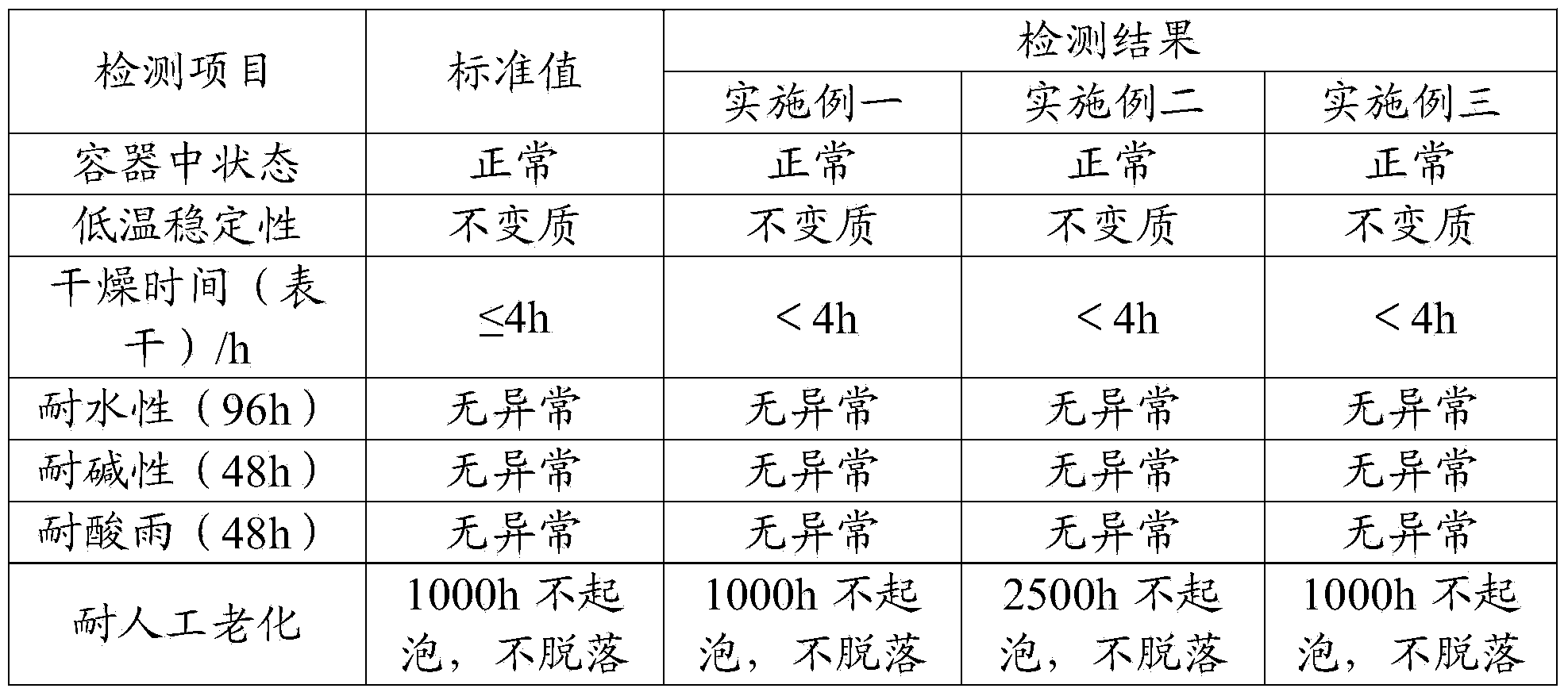

Embodiment 1

[0096] The water-in-water colorful sand wall-like texture paint of this embodiment includes a base paint, a protective colloid solution and a continuous phase emulsion, and the weight ratio of the three is: 30:40:30.

[0097] The components contained in the base paint and the weight content of each component in the base paint are: 40 parts of elastic pure acrylic emulsion, 3 parts of protective colloid solution, 0.2 part of wetting agent, 0.2 part of dispersant, 0.3 part of defoamer, bactericidal 0.1 parts of agent, 2 parts of covering polymer, 40 parts of texture aggregate, 2 parts of film-forming aid, 0.2 parts of thickener, and 12 parts of water.

[0098] The components contained in the protective colloid solution and the weight content of each component in the protective colloid solution are: 10 parts of protective colloid powder, 4 parts of retarder calcium chloride, 85 parts of water, and 1 part of wetting agent.

[0099] The continuous phase emulsion is silicon acrylic ...

Embodiment 2

[0111] The basic process of this example is the same as Example 1, the difference is that in the water-in-water colorful sand wall texture paint, the anionic emulsion in the base paint uses modified silicon acrylic emulsion, and the continuous phase emulsion uses fluorocarbon emulsion, which is further improved The weatherability of the coating.

[0112] The water-in-water colorful sand wall texture paint of this embodiment includes a base paint, a protective colloid solution and a continuous phase emulsion, and the weight ratio of the three is: 30:35:35.

[0113] The components of the base paint and the weight content of each component are as follows: 40 parts of modified silicone acrylic emulsion, 3 parts of protective colloid solution, 0.2 part of wetting agent, 0.2 part of dispersant, 0.3 part of defoamer, 0.1 part of bactericide, 2 parts of covering polymer, 40 parts of texture aggregate, 2 parts of film-forming aid, 0.2 part of thickener, and 12 parts of water.

[0114]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com