Tangential Loop Tubular Heterogeneous Reactor

A heterogeneous, reactor technology, applied in chemical/physical/physicochemical fixed reactors, etc., can solve the problems of unstable reaction temperature, static electricity, reaction pressure, etc., to reduce the risk of leakage, low equipment investment, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

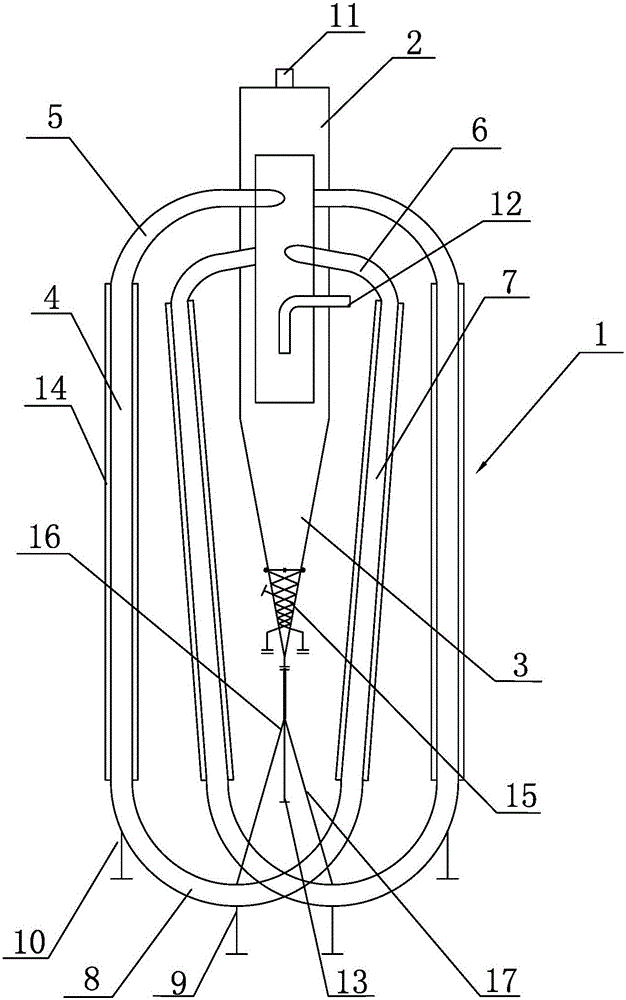

[0024] Tangential loop pipe type heterogeneous reactor of the present invention, as figure 1 As shown, it includes several groups of reaction circulation pipes 1, gas-liquid separators 2 and inverted conical liquid-solid cyclone separators 3 for mixed reactions of gases, liquids and solids, and the reaction circulation pipes 1 include reaction risers 4 , a tangential inlet section 5, an obliquely downward outlet section 6, a reaction downcomer section 7 and an arc connection section 8, the lower end of the reaction riser section 4 communicates with the lower end of the reaction downcomer section 7 through an arc connection section 8, The upper end of the reaction riser section 4 communicates with the gas-liquid separator 2 through the tangential inlet section 5, and the gas-liquid separator 2 communicates with the reaction downcomer section 7 through the inclined downward outlet section 6, and the inclined downward outlet section 6 is located at Tangential to the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com