Water-based cold cut road marking coating and preparation method thereof

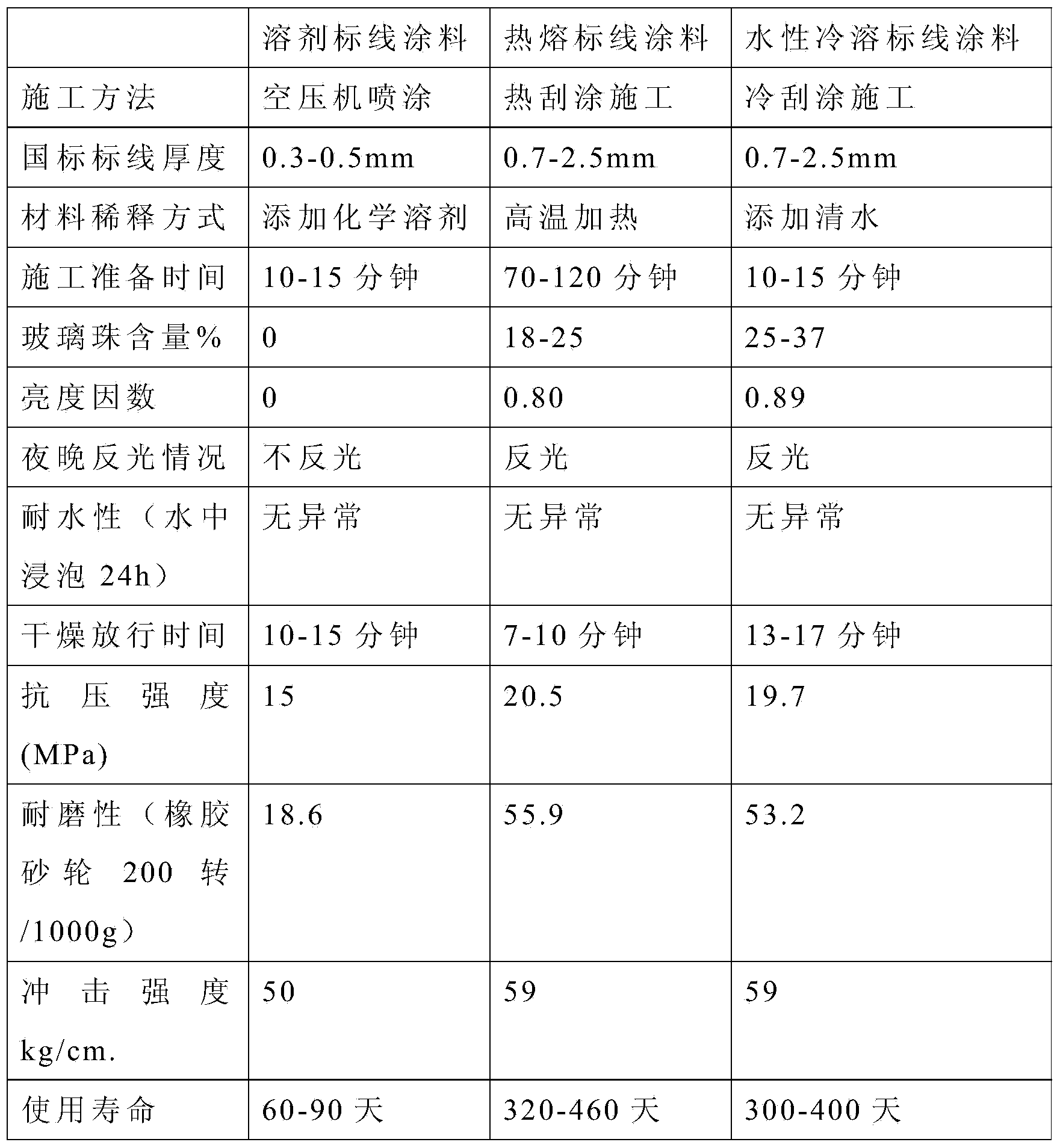

A road marking and water-based technology, applied in the field of coatings, can solve the problems of service life discount, difficulty in guaranteeing the hardness and strength of the coating, and inability to adhere enough glass reflective beads, so as to achieve energy saving and consumption reduction, reduce construction costs, Effect of increasing coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

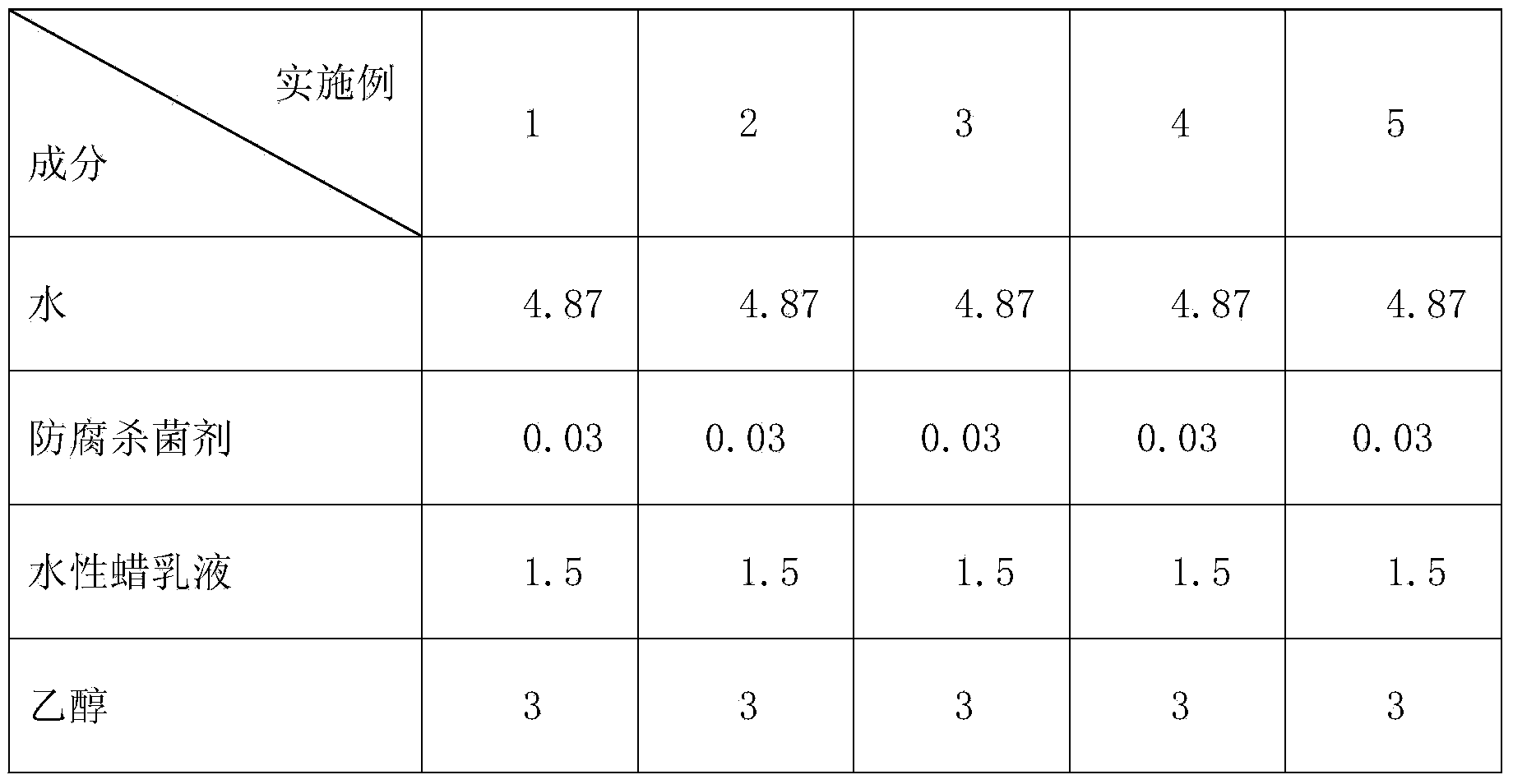

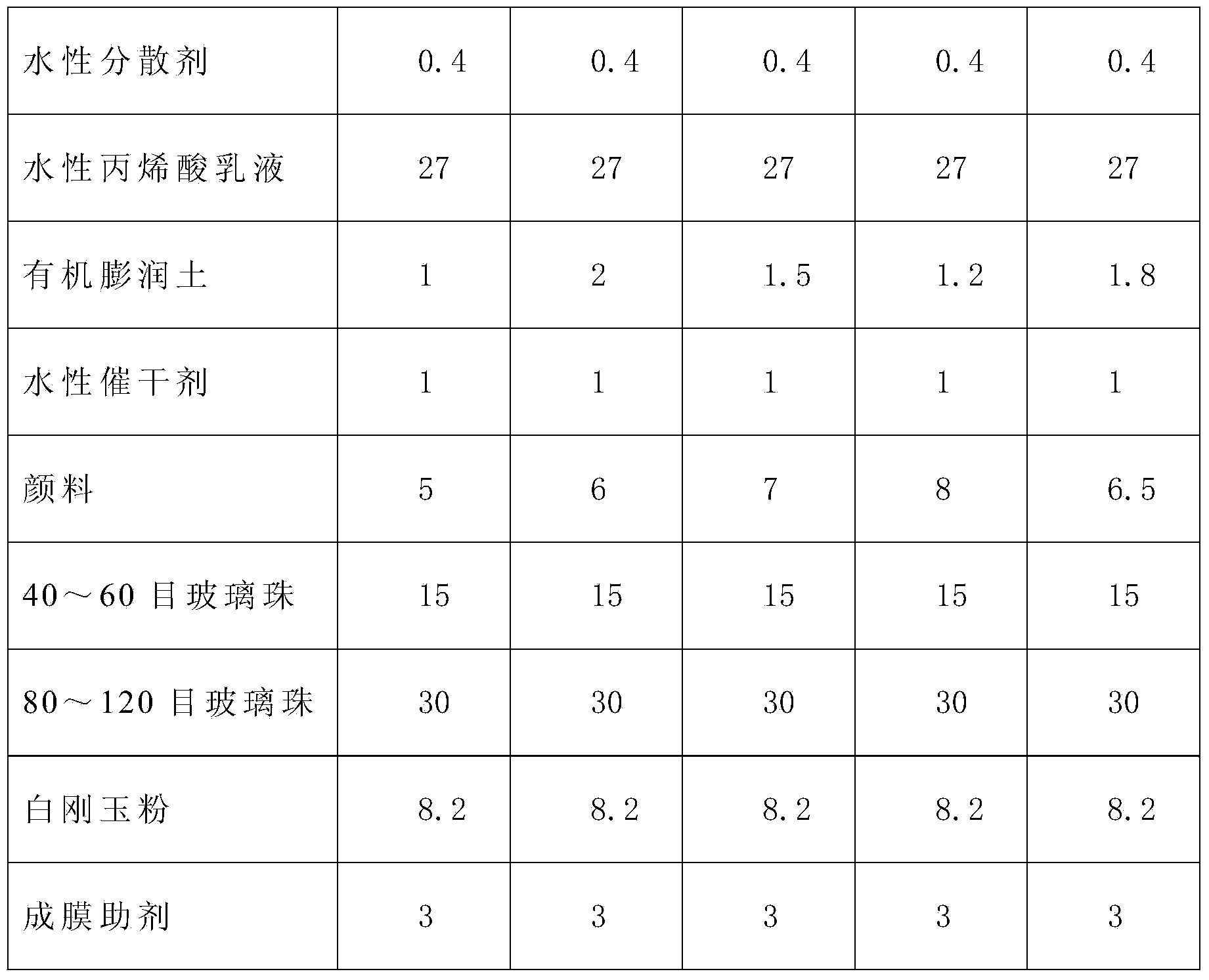

[0022] Mix and stir the components in the formula described in Table 1 to prepare a water-based cold-melt road marking paint. The KU viscosity of the prepared water-based cold-melt road marking paint is 300-500, which is suitable for use when the temperature is not lower than 5°C. Construction, easy to use in winter in the north.

[0023] Table 1 Water-based cold-melt road marking paint (parts by weight)

[0024]

[0025]

[0026] In Examples 1 to 5, the antiseptic and bactericide are mainly used for antisepsis and sterilization, which can prolong the storage period of the paint. The water-based wax emulsion can improve the anti-pollution performance of the road surface, making it have the self-cleaning effect of lotus leaves. Ethanol speeds up the drying of paint and also acts as an antifreeze. The water-based dispersant can disperse the powder and improve the smoothness of the paint film. Organic bentonite can increase viscosity and prevent sedimentation. Water-bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com