Touch screen electrode and manufacturing method thereof

A technology for electrode manufacturing and touch screen application in the field of touch screen electrodes and its manufacturing, which can solve the problems of high cost of narrow frame requirements and unsatisfactory line width and line spacing, and achieve the effects of convenient operation, avoiding ink penetration, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

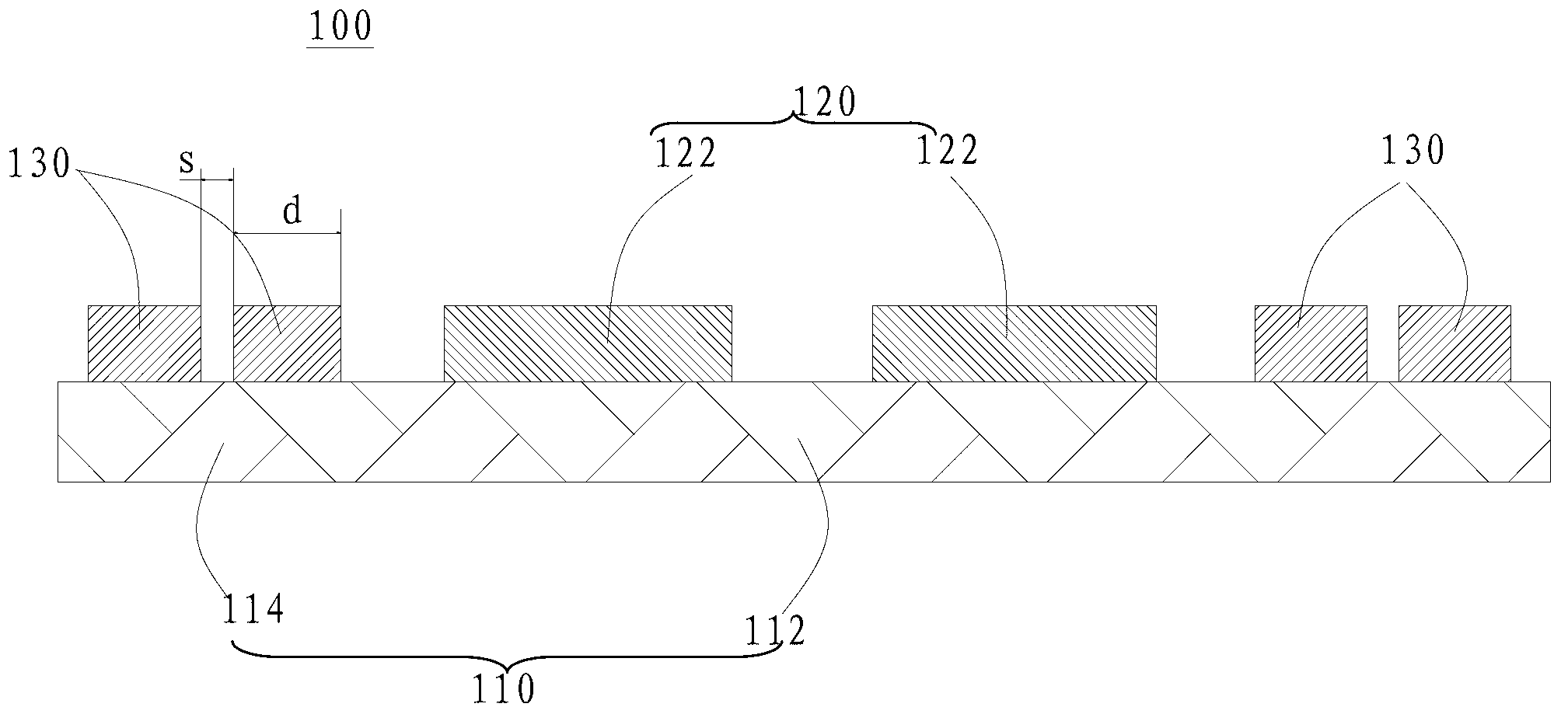

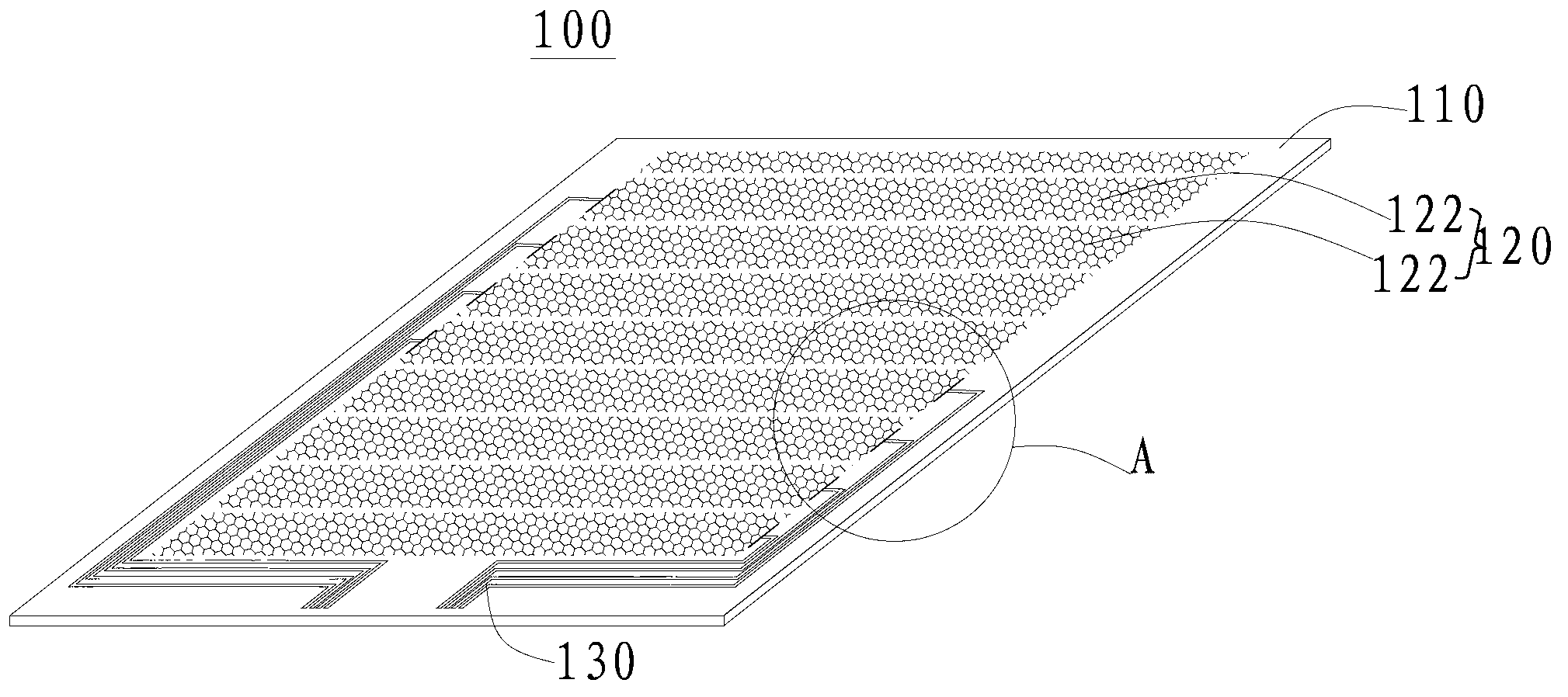

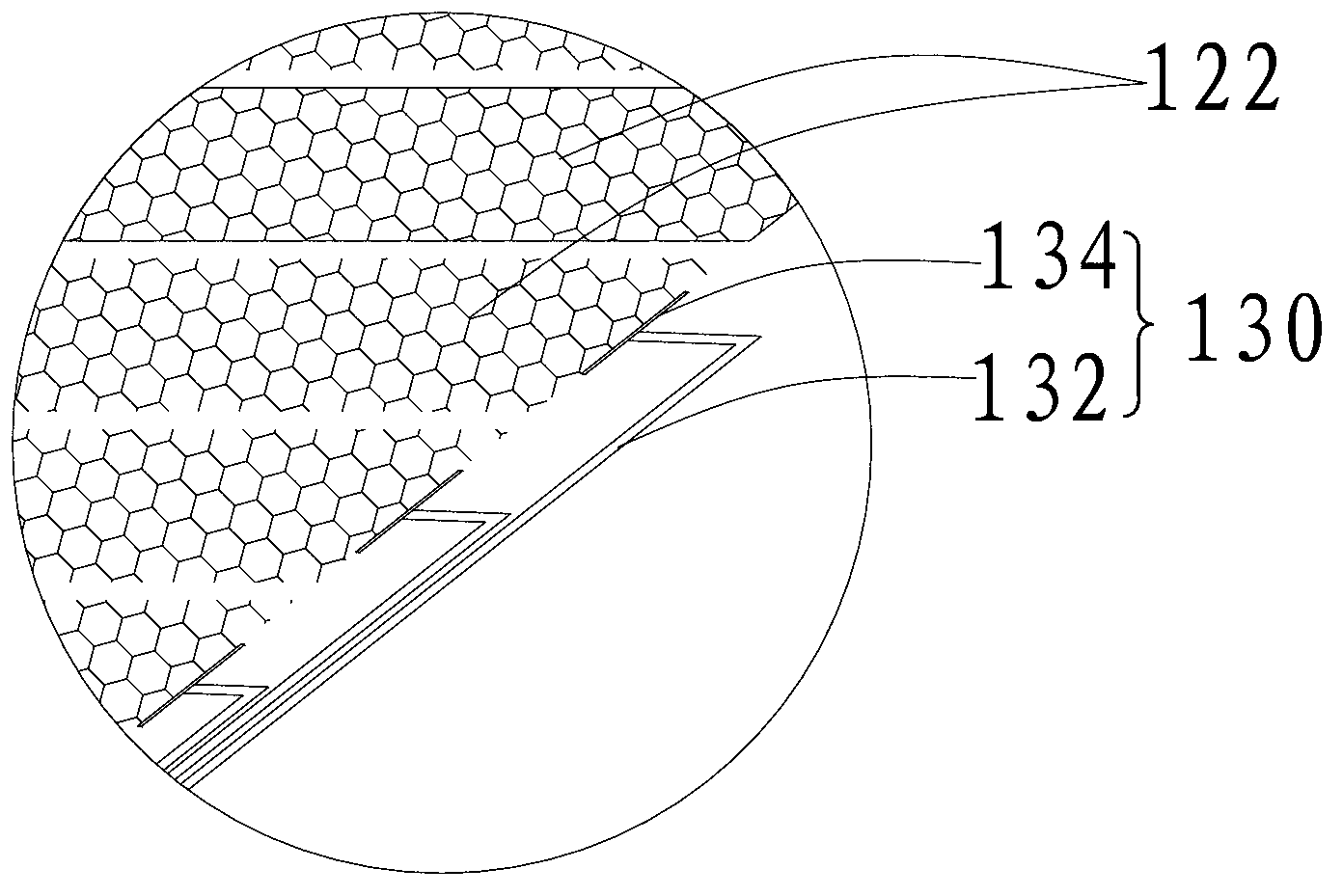

[0040] see figure 1 , figure 2 with Figure 2A , a touch screen electrode 100, including a substrate 110, a conductive layer 120 and photosensitive silver paste electrode leads 130. The substrate 110 includes a display area 112 and a frame area 114, the display area 112 matches the frame area 114, the display area 112 is located in the center, generally rectangular or square, and the display area 112 and the frame area 114 are complementary in shape. The bezel area 114 is generally located at the edge of the touch screen. The display area 112 displays a user operation interface, and the frame area 114 is used for arranging electrode leads. The conductive layer 120 is attached to the display area 112 and includes a plurality of conductive pattern regions 122 , and the plurality of conductive pattern regions 122 are insulated from each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com