Preparation method of flexible copper electrode pattern in micron level wire width

A copper electrode, micron-scale technology, applied in the field of microelectronic materials, can solve the problems of affecting contrast, slow wiring speed, and diffusion, etc., and achieve the effects of tolerance to repeated folding, long service life, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

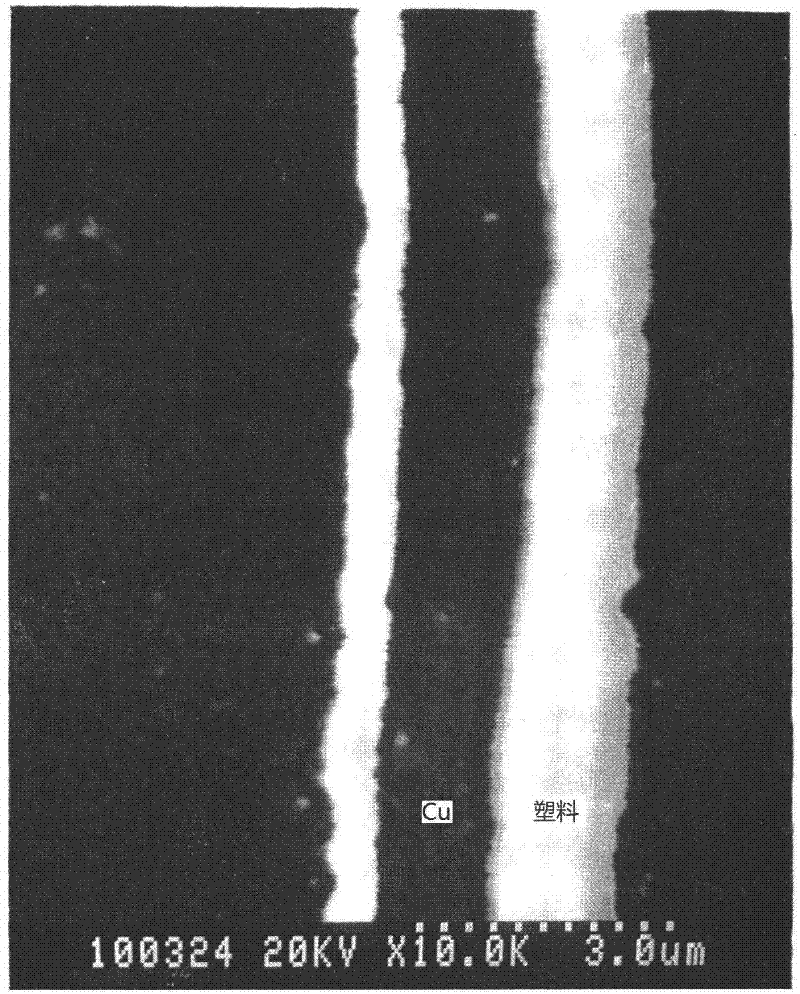

Image

Examples

Embodiment 1

[0023] Rinse the polyethylene terephthalate substrate with deionized water, ethanol, and acetone, dry it, place it in a 0.01% ethanol solution of 3-mercaptopropyltrimethoxysilane, and soak it for 4 hours , taken out, rinsed with ethanol, and dried to obtain a surface-modified plastic substrate.

[0024] The modified substrate was placed under a photomask and irradiated with ultraviolet light with a wavelength of 254 nm for 10 minutes.

[0025] Dissolve 1 g of palladium chloride, 5 g of hydrochloric acid, 5 g of trisodium citrate, and 1 g of potassium borohydride in 500 mL of deionized water. After the dissolution is complete, add deionized water until the volume of the solution is 1 L to obtain a catalytic activation solution.

[0026] Place the irradiated substrate in the above solution for 12 hours, take it out, wash it, and dry it.

[0027] Dissolve 7g of copper sulfate, 30g of sodium potassium tartrate, 4g of sodium hydroxide, 2g of sodium carbonate, 1g of nickel chloride...

Embodiment 2

[0030] Rinse the polyimide substrate with deionized water, ethanol, and acetone, dry it, place it in a methanol solution of 0.01% 3-aminopropyltrimethoxysilane, soak it for 2 hours, take it out, and wash it with methanol Rinse and dry to obtain a surface-modified plastic substrate.

[0031] The modified substrate was placed under a photomask and irradiated with ultraviolet light with a wavelength of 365 nm for 30 minutes.

[0032] Dissolve 0.1 g of palladium chloride, 1 g of hydrochloric acid, 1 g of trisodium citrate, and 0.5 g of potassium borohydride in 500 mL of deionized water. After the dissolution is completed, add deionized water until the volume of the solution is 1 L to obtain a catalytic activation solution.

[0033] Place the irradiated substrate in the above solution for 8 hours, take it out, wash it, and dry it.

[0034] Dissolve 10g of copper sulfate, 40g of sodium potassium tartrate, 6g of sodium hydroxide, 3g of sodium carbonate, 2g of nickel chloride, and 8g...

Embodiment 3

[0037] Rinse the polymethyl methacrylate substrate with deionized water and ethanol, dry it, place it in a solution of 5% 3-aminopropyltriethoxysilane in isopropanol, soak it for 2 hours, take it out , washed with isopropanol, and dried to obtain a surface-modified plastic substrate.

[0038] The modified substrate was placed under a photomask and irradiated with ultraviolet light with a wavelength of 365 nm for 20 minutes.

[0039] Dissolve 0.5 g of palladium chloride, 2 g of hydrochloric acid, 3 g of trisodium citrate, and 0.8 g of potassium borohydride in 500 mL of deionized water. After the dissolution is completed, add deionized water until the volume of the solution is 1 L to obtain a catalytic activation solution.

[0040] Place the irradiated substrate in the above solution for 10 hours, take it out, wash it, and dry it.

[0041] Dissolve 8g of copper sulfate, 37g of sodium potassium tartrate, 5g of sodium hydroxide, 2g of sodium carbonate, 1g of nickel chloride, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com