Hot treatment device and method

A technology of heat treatment device and heat treatment method, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as excessive heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

[0069]

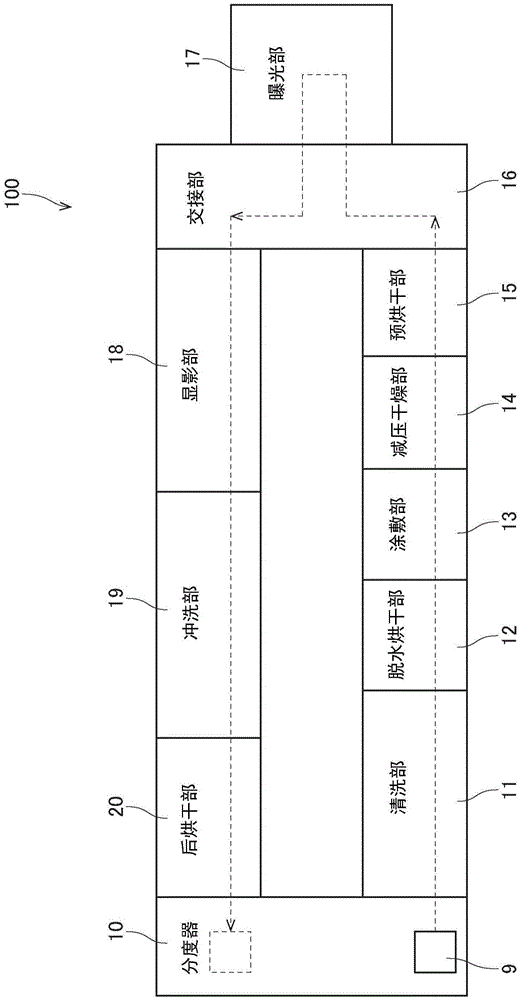

[0070] figure 1 It is a schematic diagram showing the structure of the substrate processing apparatus 100 provided with the heat processing apparatus of the first embodiment. The substrate processing apparatus 100 of this embodiment is an apparatus for applying a resist solution, exposing, and developing after exposure to a rectangular glass substrate 9 (hereinafter, simply referred to as “substrate 9 ”) used in a liquid crystal display device.

[0071] Such as figure 1 As shown, the substrate processing apparatus 100 has an indexer 10, a cleaning unit 11, a dehydration drying unit 12, a coating unit 13, a decompression drying unit 14, a pre-drying unit 15, a transfer unit 16, an exposure unit 17, a developing unit 18, Rinsing section 19 and post-drying section 20. The processing units 10 to 20 of the substrate processing apparatus 100 are arranged adjacent to each other in the order described above. Such as figure 1 As indicated by the dotted line arrows in , t...

no. 2 approach >

[0107]

[0108] Next, a second embodiment of the present invention will be described. In addition, the heat processing apparatus 1 of this embodiment is the same as the heat processing apparatus 1 of the first embodiment, and can also be applied to the cooling section in the dehydration drying section 12 of the substrate processing apparatus 100, the cooling section in the pre-drying section 15, and the post-drying section. The cooling part in the drying part 20.

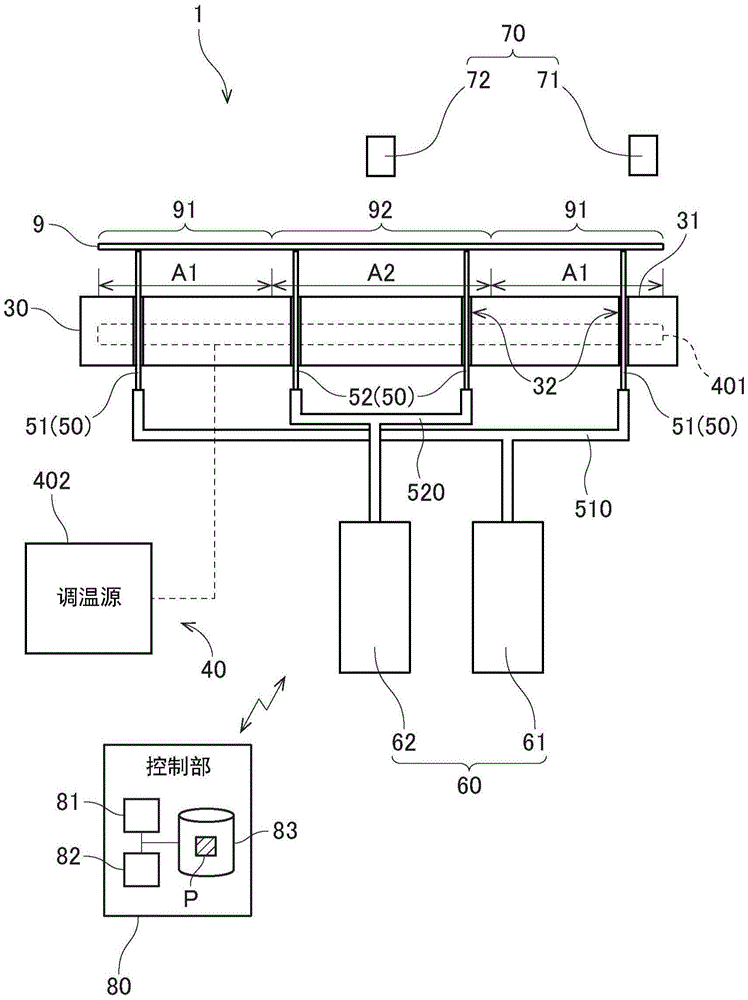

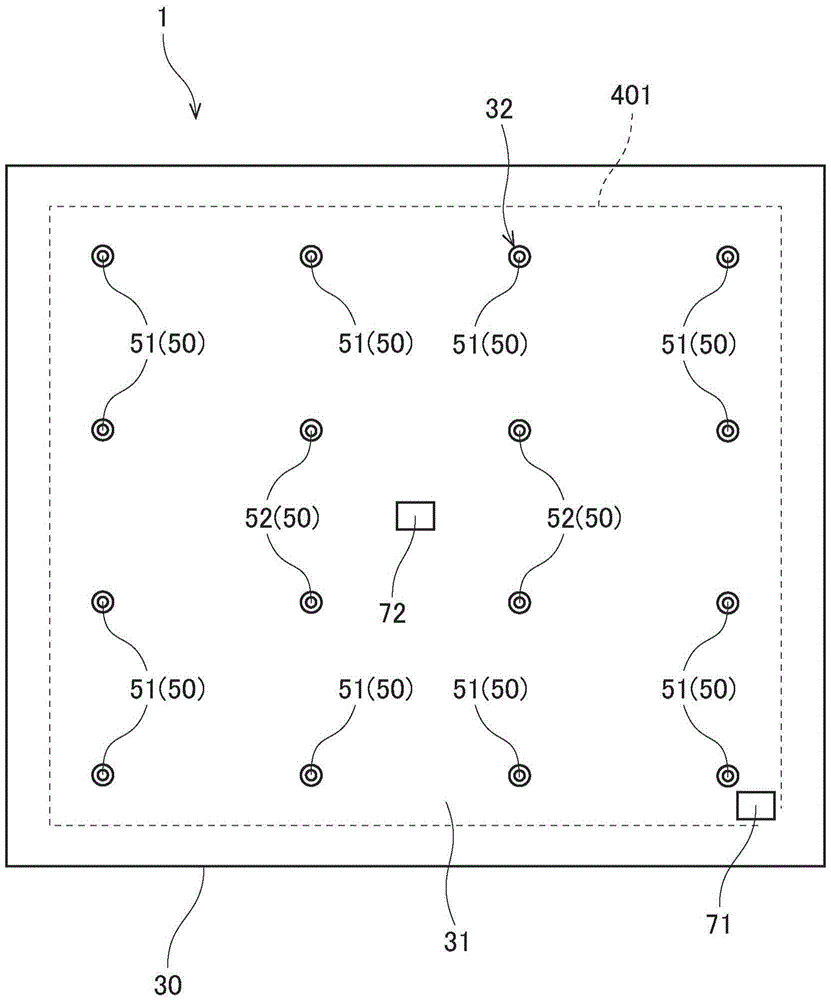

[0109] Image 6 It is a schematic sectional view of the heat processing apparatus 1 of 2nd Embodiment. Figure 7 It is a schematic plan view of the heat treatment apparatus 1 . Such as Image 6 as well as Figure 7 As shown, the heat treatment apparatus 1 of this embodiment has a heat treatment plate 30 , a temperature adjustment mechanism 40 , a plurality of lift pins 50 , a lift mechanism 60 , a temperature measurement unit 70 and a control unit 80 . In the following description, differences from the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com